Introduction – Pulsafeeder Isochem RGT IOM User Manual

Page 6

1

1. Introduction

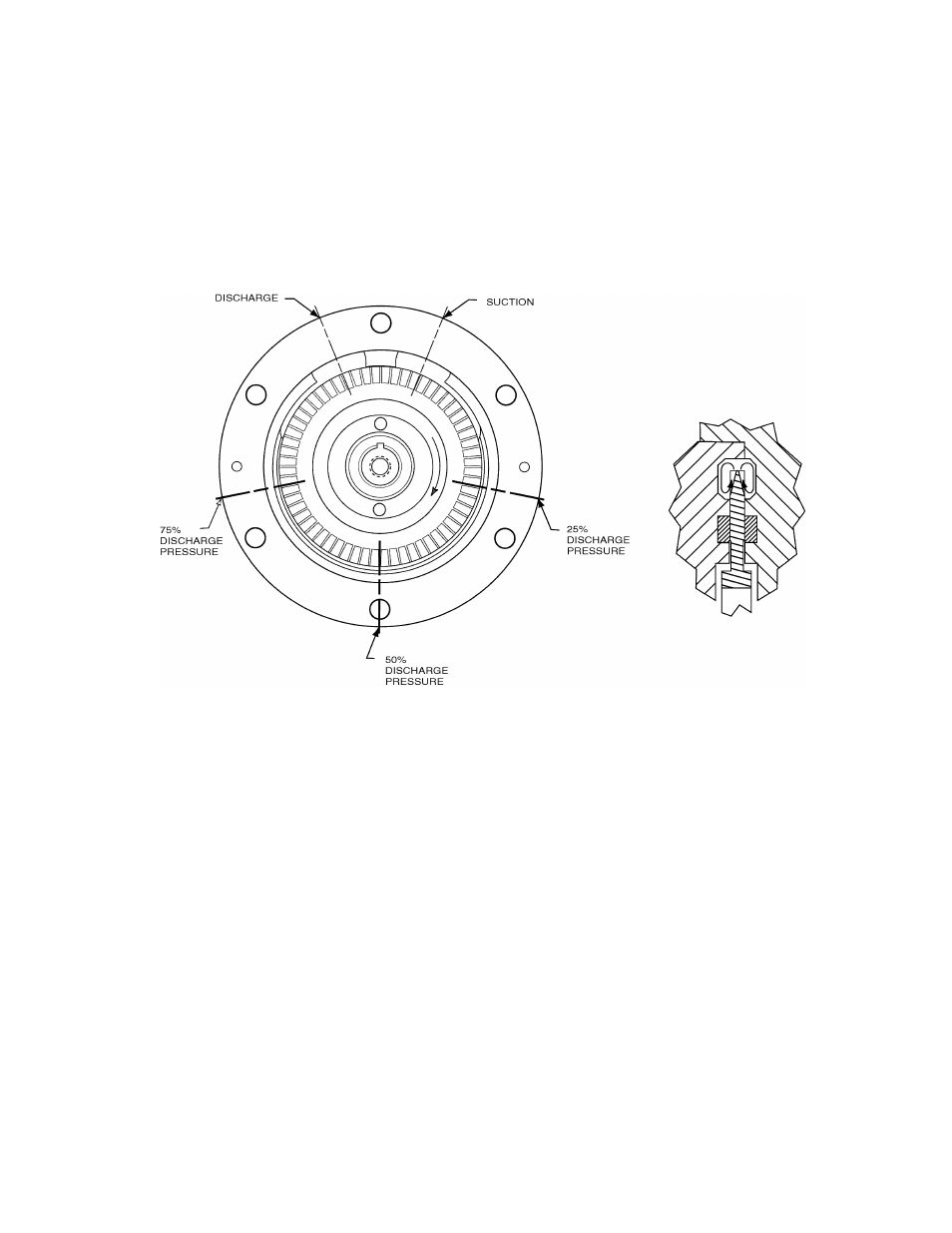

The Isochem® Regenerative Turbine pump (RGT) is uniquely different from the more familiar

types of pumps. As the pumped liquid progresses from suction to discharge, it is continuously

circulated between the impeller vanes and the walls of the flow passage in a helical path, the axis

of which coincides with the flow passage. This process results in a significantly higher buildup

of pressure than that which occurs in the similar but simpler centrifugal pump.

Figure 1

The turbine pump is in many ways an intermediate between the centrifugal and positive

displacement types. As discharge pressure increases, flow decreases and the power required to

drive the pump increases.

Flow is directly controlled by discharge pressure: the greater the pressure, the lower the flow

rate. This can be most readily achieved by throttling the discharge; however care must be taken

to not exceed the power level of the motor. Flow can be regulated using a variable bypass

system, allowing operation at reduced pressure and power draw by dumping excess flow, usually

back to a supply tank.

A very small clearance is maintained between the impeller, wear plates, and other internal

surfaces. Since the impeller floats freely in the axial direction relative to the pump, a film of fluid

is present on either side of the impeller so that there is no contact and negligible wear between

impeller and wear plates.

Isochem RGT pumps use magnetic coupled, sealless technology, which eliminates the need for a

rotary mechanical seal and enables the pump to handle hazardous fluids safely with zero leakage.