Save these instructions, Bwg super jet application recommendations – Balboa Water Group Super (Cyclone) Jet User Manual

Page 2

SAVE THESE INSTRUCTIONS

BWG Super Jet Application Recommendations

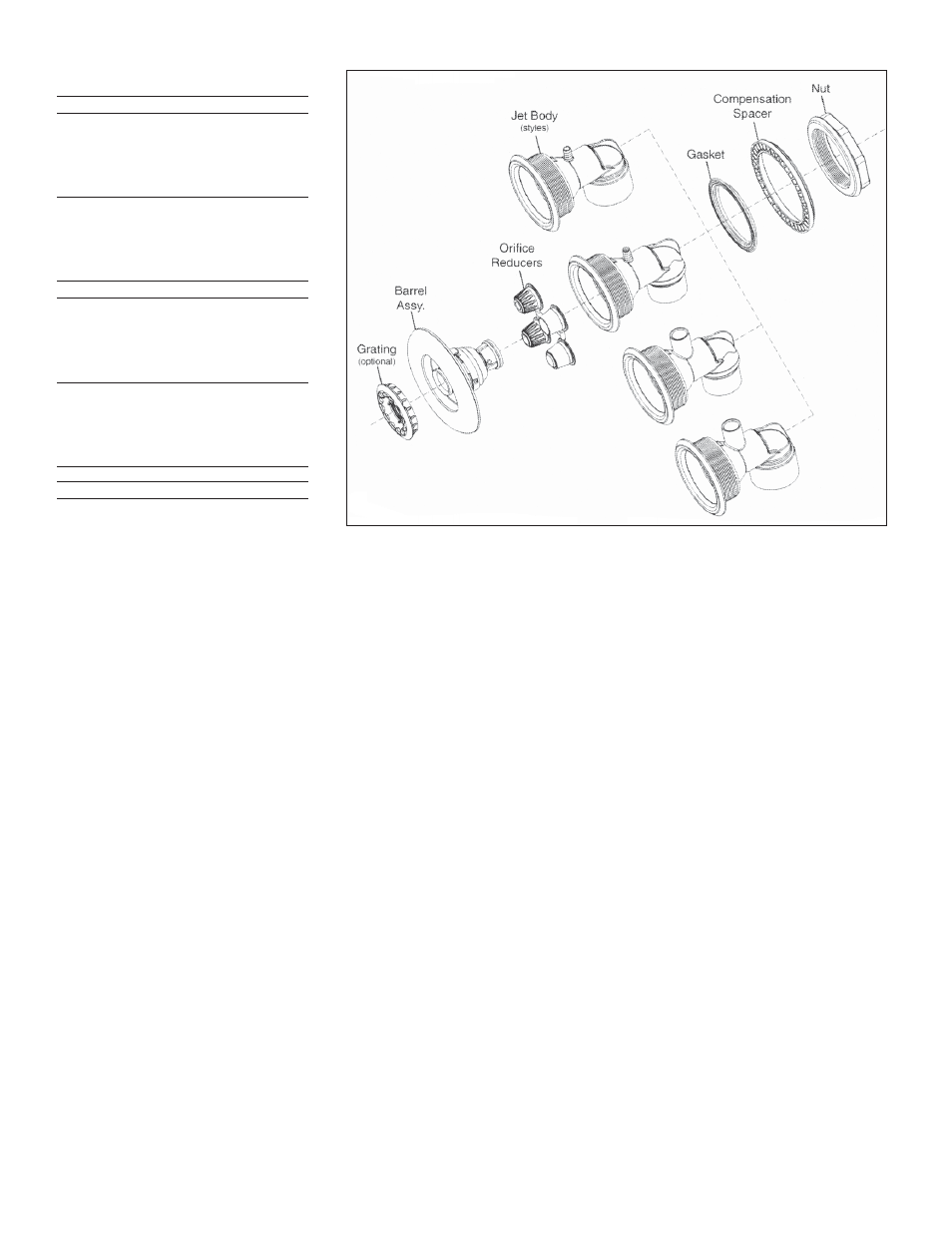

Parts List

Part No. Description

900921XX Grating

Super Jet Regular Barrel Scallop Assy.

900926XX Smooth

900927XX Emerald

900928XX Diamond

900929XX Textured

Super Jet Large Barrel Scallop Assy.

900930XX Smooth

900931 XX Emerald

900932XX Diamond

900933XX Textured

943564 Orifice Reducers

Super Jet Body’s

90093800 3/8” B x 1-1/2” S, 90°

90093900 3/8” B x 2” S, 90°

90094000 1/2” S x 1-1/2” S, 90°

90094100 1/2” S x 2” S, 90°

Super Jet Body’s (with Check Valve)

90093400 3/8” B x 1-1/2” S

90093500 3/8” B x 2” S

90093600 1/2” B x 1-1/2” S

90093700 1/2” B x 2” S

47950000 Compensator

47940000 Nut

946600 “L” Gasket

47930000 Flat Gasket

This state-of-the-art Super Jet technology features several unique installation features.

Thoroughly read and understand these application recommendations before installing this jet.

While installation is simple, there are many variables with each spa manufacturer’s process that are beyond our control.

Therefore we

STRONGLY RECOMMEND that every OEM thoroughly test the application of this jet before using it on their

production line.

The unique design feature of the Super Jet creates a seal at the front (acrylic side) of the spa. There are advantages to sealing

at the front of the spa.

Acrylic is an optimal sealing smooth surface, much better than fiberglass,

UÊ

Potential leaks, or fiberglass delamination can be prevented by preventing possible water migration.

UÊ

To fully gain these advantages, the mounting surface must be flat!

Each OEM should carefully survey every jet recess. A flat sealing area 6 inches in diameter is required. Ensure the cove which

is formed at the bottom of a jet recess is fully drawn down and not allowed to drift into the jet sealing area. The hole must be

drilled in the center of the recessed area. The sealing area must be consistently flat.

Examine the drilling process. The hole must be drilled no larger than 3.90 in.

Do not allow the hole saw to “work or walk” during drilling! This could produce a hole that is off center. or not round. Also.

the walls of the hole could be incorrectly cut on an angle. Ensure the hole saw is sharp. A dull saw will create excessive heat.

Excessive heat will cause the acrylic to curl up at the edge of the hole, leaving a burr. Any of these conditions will impede the

sealing process.

Following these recommendations will provide trouble free operation of the Super jet. If you have application questions,

please call (714) 384-0384.

Figure 1

943584 Rev. B October 12, 2009