Troubleshooting – Karcher HKF 200 K2 User Manual

Page 36

-

16

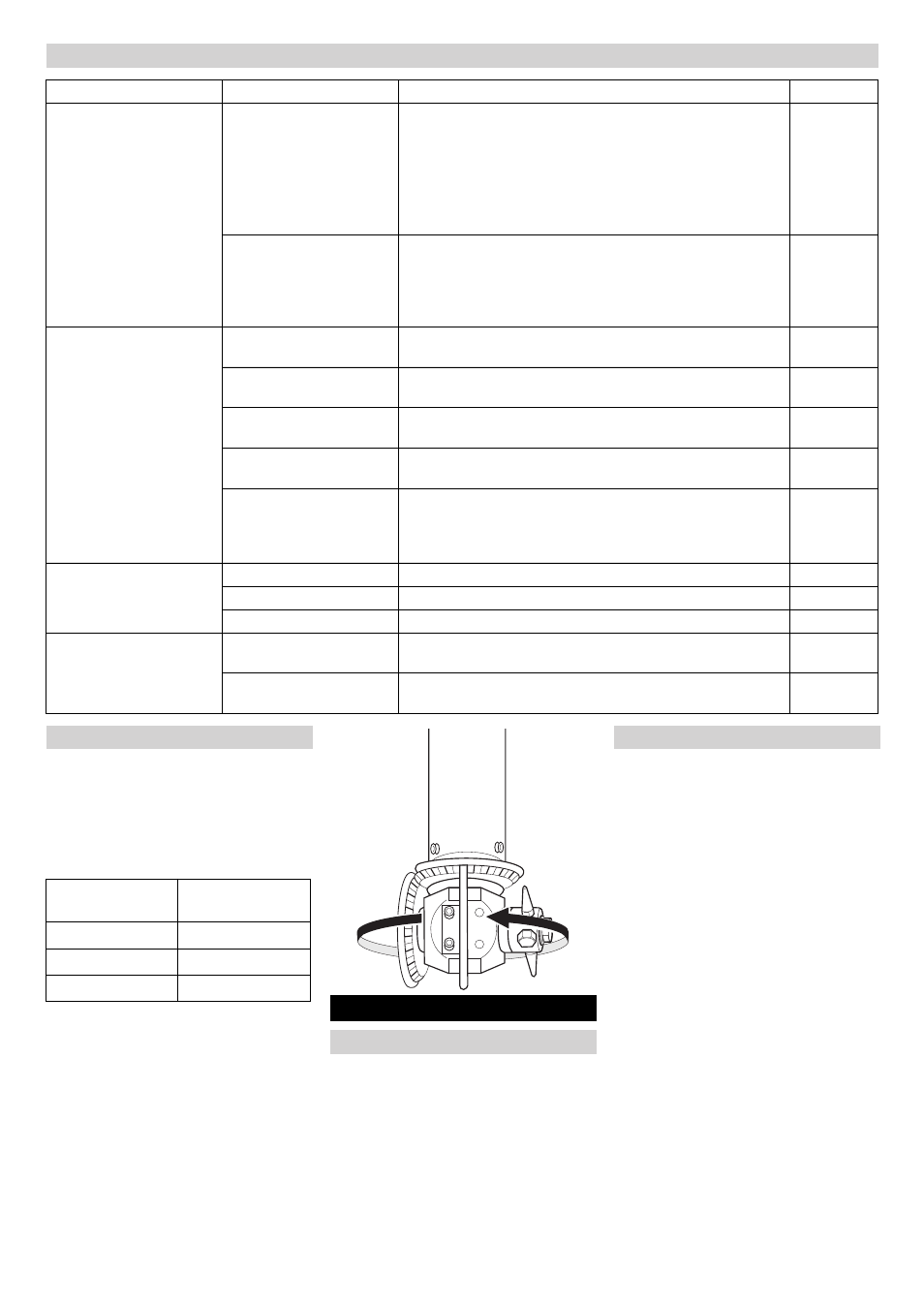

When replacing the compressed air hoses

between the compressed air motor and the

baseplate, the motor and the connections

in the baseplate must be linked as per the

following table:

After replacing defective compressed air

hoses, the rotation direction of the cleaning

head must be checked. The correction ro-

tation direction is indicated in the following:

ƽ

Danger

Risk of accident while working on the unit!

During all tasks:

Remove voltage from and secure high

pressure pump at the main switch.

Shut off the cleaning liquid supply.

Close the steam supply.

Switch off the drive of the cleaning

heads and shut off the compressed air

supply.

Operator

Work designated with the sign “Opera-

tor” may only be carried out by persons

who have been instructed in the safe

operation and maintenance on the high

pressure plant.

Customer Service

Work designated with the sign “Cus-

tomer Service” may only be done by the

fitters of Kärcher Customer Service.

Maintenance schedule

Time

Activity

Performance

of whom

daily

Check the maintenance

unit for compressed air.

ƽ

Danger

Danger through compressed air. Shut off the compressed air

supply and let existing compressed air escape from the main-

tenance unit prior to performing maintenance work.

–

Let off water in the water separator.

–

Fill the proportional oiler with a suitable lubricant. Oil type -

see operating instructions of the compressed air motor.

Operator

Perform a visual inspec-

tion of the seal underneath

the baseplate of the tank

cleaning device and on the

adapter.

ƽ

Danger

Risk of injury and explosion on account of defective seal.

Check the seals for the type of application, contamination,

damage and wear. Replace defective seals.

Operator

weekly or after 40 operat-

ing hours

Visible inspection of the

high pressure hoses

Check the high pressure hoses for damages; replace dam-

aged hoses.

Operator

Check the transport safety

device.

Check the transport safety device for its function and flawless

condition.

Operator

Check the tensioning

units.

Check the tensioning units that fasten the baseplate to the

dome of the tank to be cleaned for ease of movement.

Operator

Visual inspection of the

protective bows.

Check the protective bows of the cleaning heads for damage.

Repair or replace defective protective bows.

Operator

Check the cleaning heads

for ease of movement.

Bring the tank cleaning device into a working position outside

the container, start up the cleaning heads without cleaning liq-

uid and check for proper operation and ease of movement of

the rotational drive.

Operator

monthly or after 160 oper-

ating hours

Check screws for tight fit.

Check that all screws are fitted tightly.

Operator

Check the joint bolt.

Check the joint bolt for wear. Replace defect parts

Operator

Check the folding rack.

Check the ease of movement of the folding rack.

Operator

Every 600 operating hours Service the compressed

air motors.

Maintenance tasks as per the operating instructions of the

compressed air motors.

Skilled per-

sonnel

Check the tooth play of the

bevel wheels.

Check the tooth play of the bevel wheels in the cleaning

heads, adjust if necessary.

Customer

Service

Maintenance Works

Replace the compressed air hoses

Compressed air

motor

Base plate

1

1

2

P2

EXH

EXH

Troubleshooting

Troubleshooting notes

Who may remedy faults?

36

EN