Karcher HKF 200 K2 User Manual

Page 22

-

2

–

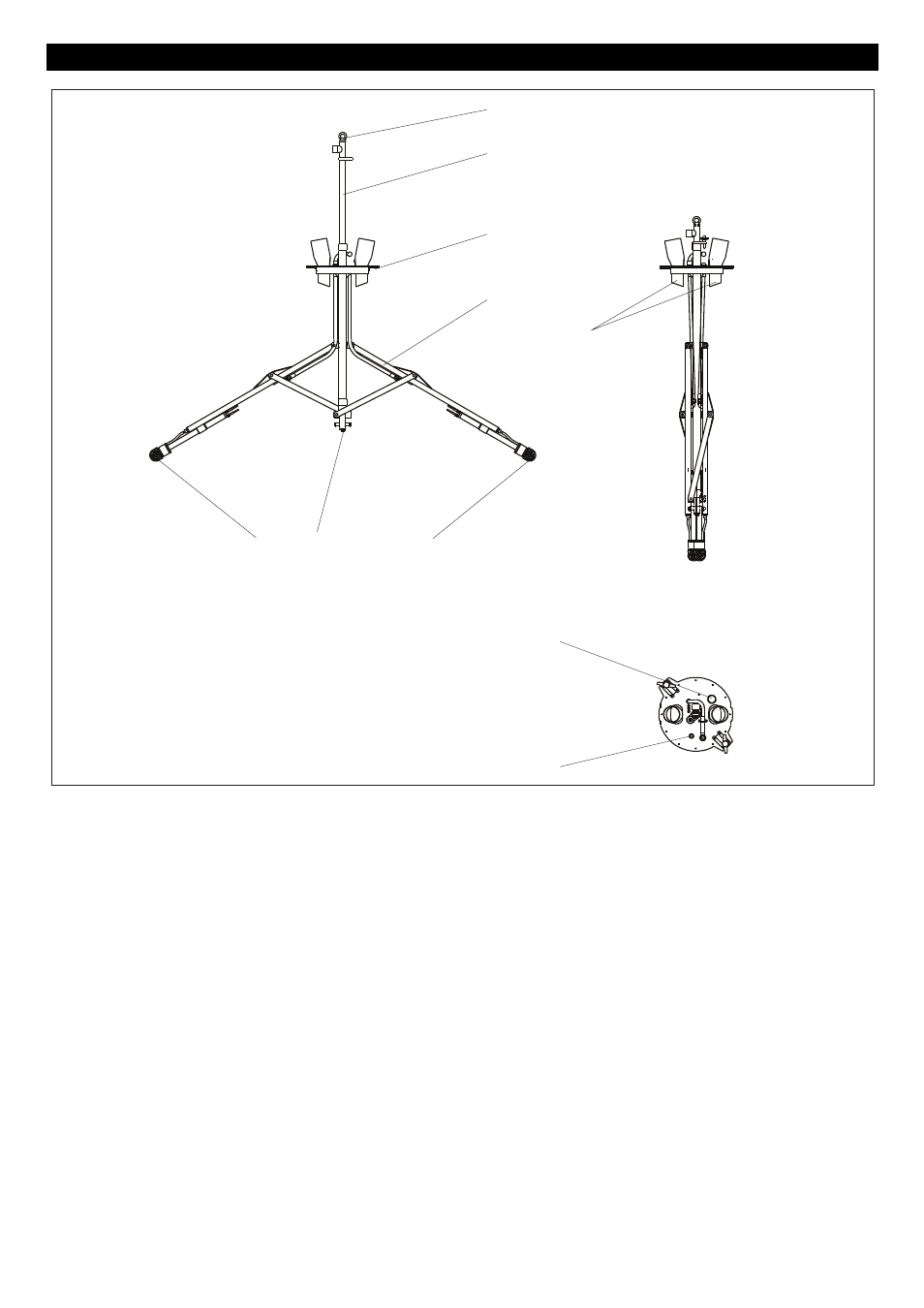

The tank cleaning device consists of a

base plate (1), folding rack (2), draw

pipe (3) and two cleaning heads (4) with

compressed air drive. The tank clean-

ing device is fastened to a lift unit with

the ring screw (5) during operation. The

folding rack moves the cleaning heads

into the extended/rectracted position

(A) or into the working position (B).

–

In the extended/retracted position, the

draw pipe must be slid down and fas-

tened to the base plate by means of the

transport lock. The cleaning heads are

tilted downwards. In this position, the

tank cleaning device is extended into

the tanks and extracted from them.

–

In the working position, the base plate is

tensioned tightly onto the tank dome by

means of the tensioning units. The vac-

uum/high pressure valve (8) equalizes

the pressure between the container and

the atmosphere. The draw pipe is

pulled up to the mark toward the top by

means of the lifting unit. Here, the

cleaning heads are swivelled into the

working position.

–

Steam to heat the tank can be drawn in

via the draw pipe and the steam noz-

zles (6).

–

For containers without floor drain

valves, the remaining liquid can be suc-

tioned off through the suction opening

(9) by means of a site-supplied suction

device.

–

The nozzles on the cleaning heads turn

around two axles and therefore touch

every place in the container. They are

driven by compressed air motors.

–

After the cleaning, air can be chan-

nelled in and out of the tank to dry it via

the two warm air connections (7).

Function

B

A

9

8

7

4

4

6

5

3

1

2

22

EN