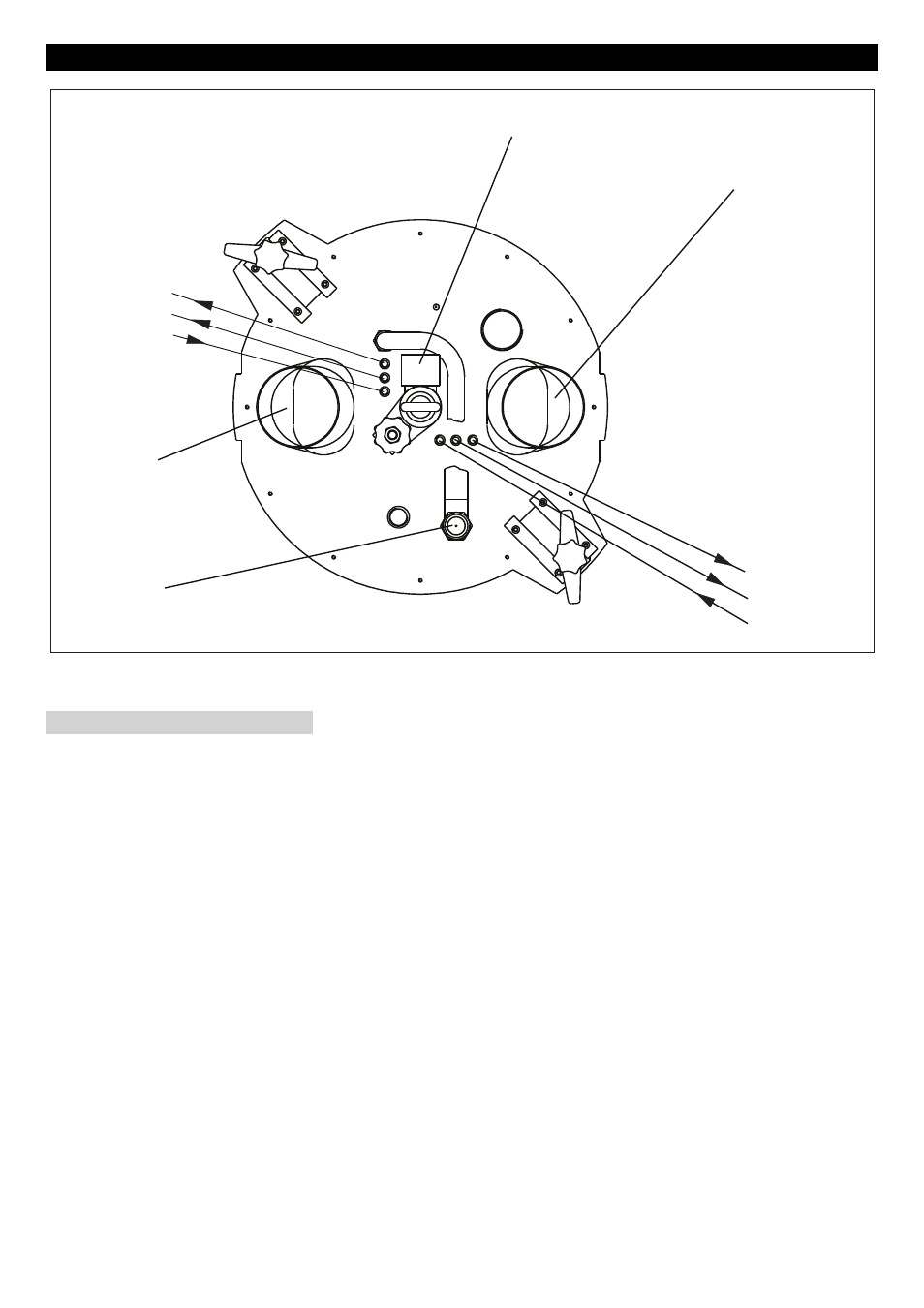

Start up exh 1 p2 exh 1 p2 a b c c – Karcher HKF 200 K2 User Manual

Page 33

-

13

Prior to the initial startup, the supply lines

from the site-supplied supply units must be

connected to the tank cleaning device.

Caution

In order to avoid damage to the com-

pressed air drive by condensation wear

and lack of lubrication, install a mainte-

nance unit into the compressed air supply.

This maintenance unit must be laid out as

follows:

–

Air throughput of 60 m

3

/h (with standard

conditions)

–

Pressures of up to 0.6 MPa (for safety

reasons)

–

The hose line between the mainte-

nance units and the tank cleaning de-

vice must not be longer than 3 m.

The maintenance unit consists of:

–

Filter

–

Water separator

–

Pressure regulator with manometer

–

Proportional oiler

Fill the proportional oiler with a suitable

lubricant. Oil type - see operating in-

structions of the compressed air motor.

Set the oiler to 50 mm

3

oil per standard

cubic meter (mm

3

/m

3

) compressed air,

see operating instructions of the com-

pressed air motor.

–

Hose size for supply air as per DIN 10

Blow the hose clean and connect it to

the compressed air connections (P2).

The exhaust air of the compressed air mo-

tors exits at the connections "1" and "EXH".

Here, you can connect mufflers or exhaust

hoses.

Note: A reflux of the exhaust air causes an

unsafe run of the compressed air motor.

Therefore, you must use large enough muf-

flers or hoses.

Start up

EXH

1

P2

EXH

1

P2

a

b

c

c

Compressed air connection

Maintenance unit

Connect supply air hose

Exhaust air

33

EN