Frost protection transport faults – Karcher BRC 50-70 W Bp User Manual

Page 16

16

English

Î

Set key switch to “0” with the cleaning

head raised.

Î

Unscrew the knurled-head screw.

Î

Remove the vacuum bar.

Î

Pull out the suction hose from the vacu-

um bar.

Î

Rinse the vacuum bar from the top with

water.

Î

Obstructions in the gap between the

slide shoes can be removed with a spat-

ula. If necessary, the slide shoes can be

unscrewed from the vacuum bar for

cleaning.

Î

Repeat the cleaning process on the

second vacuum bar.

Î

Reattach both vacuum bars to the appli-

ance in reverse sequence.

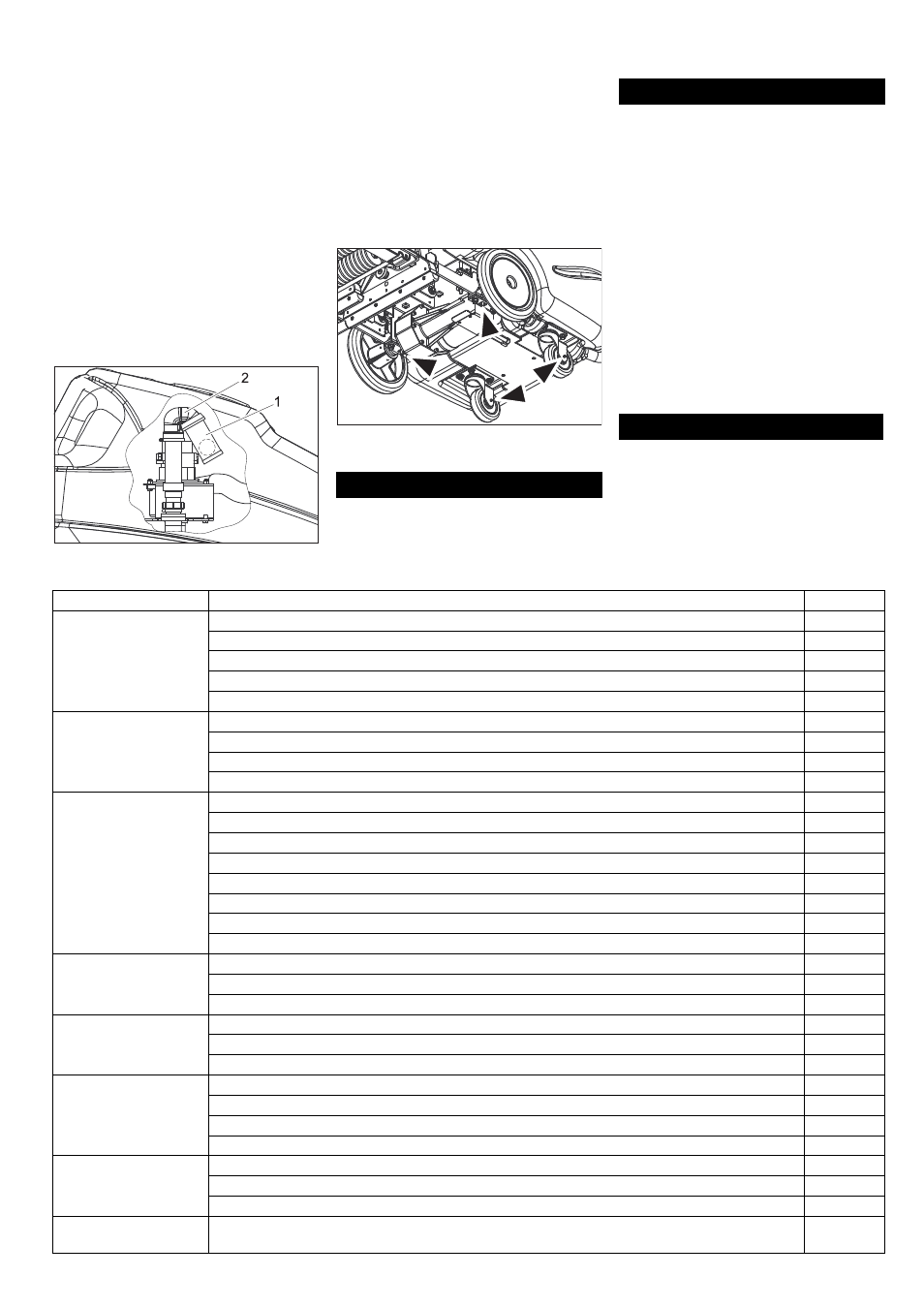

1 Sieve with floater ball

2 Pipe

Î

Clean the sieve from the outside and

rinse it.

Î

Check the mobility of the floater ball.

If it is too dirty:

Î

Hold the pipe firmly and pull out the

sieve from the pipe.

Î

Clean sieve and ball.

Î

Hold the pipe firmly and reinsert the

sieve.

Î

Lubricate the greasing nipple with a

grease press.

In case of danger of frost:

Î

Empty the fresh and dirt water reser-

voirs.

Î

Store the appliance in a frost-protected

room.

ƽ

Danger

Risk of injury! When loading or unloading

the machine, it may only be operated on

gradients of max. 2%. Drive slowly.

ṇ

Warning

Danger of damage to the control. The appli-

ance should only be operated with the drive

motor removed. The pushing speed must

not exceed 8 km/h.

Î

Remove the vacuum bar and lift up the

cleaning head prior to loading the appli-

ance via a ramp.

Î

If you want to transport the machine on

a vehicle secure it from slipping using

belts/ ropes.

Î

Secure the wheels of the machine with

wheel chocks.

ƽ

Danger

Risk of injury! Before carrying out any tasks

on the machine, set the main key to "0" and

remove it. Pull out the battery plug.

Î

Drain and dispose of the dirt water and

the residual fresh water.

In case of faults that cannot be remedied

using the table below please contact the

Cleaning the floater

Lubricating the drive axle and the steer-

ing rollers

Frost protection

Transport

Faults

Fault

Remedy

By whom

Appliance cannot be

started

Insert the battery plug on the device.

Operator

Release emergency-stop button by turning.

Operator

If battery is low, charge the battery.

Operator

Check battery cable for correct sitting.

Operator

Check battery cable for corrosion; clean, if required.

Operator

Device does not drive

or drives only slowly

Reset fuse of traction drive

Operator

If battery is low, charge the battery.

Operator

The appliance was switched on while a drive key was pressed. Release the drive switch.

Operator

Control system overheated; switch off device and let it cool down.

Operator

Insufficient vacuum

performance

Empty the dirt water reservoir.

Operator

Clean the seals between dirt water reservoir and cover and check for tightness, replace if required.

Operator

Check suction hose for blockages; clean if required.

Operator

Check connection between suction hose and vacuum bar and suction hose and the device.

Operator

Check the suction hose for tightness; replace if required.

Operator

Check if the cover on the dirt water discharge hose is closed

Operator

Clean the floater in the dirt water tank.

Operator

Reset fuse of suction turbine.

Operator

Insufficient cleaning re-

sult

Check the brushes for wear, replace if required.

Operator

Check brushes for wear and tear, clean.

Operator

If battery is low, charge the battery.

Operator

Brushes are rotating

slowly or not at all

Reset fuse of brush drive.

Operator

Check the brushes for blockage due to foreign particles, remove them if found.

Operator

If battery is low, charge the battery.

Operator

No or very little deter-

gent solution gets add-

ed

Check level of detergent solution in the fresh water tank; refill, if required.

Operator

Turn on the key Apply detergent solution - the control lamp must illuminate.

Operator

Check nozzles for blockages; clean if required.

Operator

Check fresh water filter; clean if required.

Operator

Do not add detergents

Refill detergent tank.

Operator

Press the ventilation switch for the respective tank for 30 seconds.

Operator

Flush the pipe system for the detergent with water.

Operator

The cleaning head can-

not be raised/lowered

Reset fuse of control system.

Operator