Troubleshooting, Accessories, Installing the unit (only for experts) – Karcher WRP 1000 ECO User Manual

Page 12

-

5

ƽ

Danger

Risk of accident while working on the unit.

During all tasks

Switch off the immersion pump in the

building.

–

Operator

Work designated with the sign “Opera-

tor” may only be carried out by persons

who have been instructed in the safe

operation and maintenance on the

wash plant

–

Customer Service

Work designated with the sign “Cus-

tomer Service” may only be done by the

fitters of Kärcher Customer Service or

fitters who have been authorised by

Kärcher.

Manual switching between processed/

fresh water for using fresh water in the

high-pressure cleaner (for e.g. for rinsing).

Notice

The equipment may only be installed by an

–

mechanic of Kärcher

–

or an from Kärcher authorized individual

The following requirements are necessary

in order to install the equipment:

–

frost-free room with adequate ventila-

tion and exhausts

–

Floor path for collecting sludge

–

Strong wall for fastening the system

Unpack the equpiment and dispose of the

packing material properly.

The water installation depends on the spe-

cific conditions of the existing plant compo-

nents such as

–

Type and model of high-pressure

cleaner or washing system

Note

The processed water outlet of the system is

directly connected to the water inlet of the

high-pressure cleaner. This can lead to

foam formation in the swimmer tank in

high-pressure cleaners with a swimmer

tank. In such a case, the high-pressure

cleaner must be switched to suction opera-

tioins (see separate operating instructions

of the high-pressure cleaner).

–

Type and models of building-side com-

ponents (sludge collector, pump basin,

etc.)

–

Nominal widtht, lengths and type of

channels

Hence, the water installation must be done

according to the specific local conditions.

The immersion pump specifications in the

building must meet the requirements out-

line in the "Technical Data / Immersion

Pump Requirements" section.

ƽ

Danger

Risk of injury on account of tripping and falling.

Lay the hoses of the plant in such a way

that they do not pose a risk for tripping and

falling.

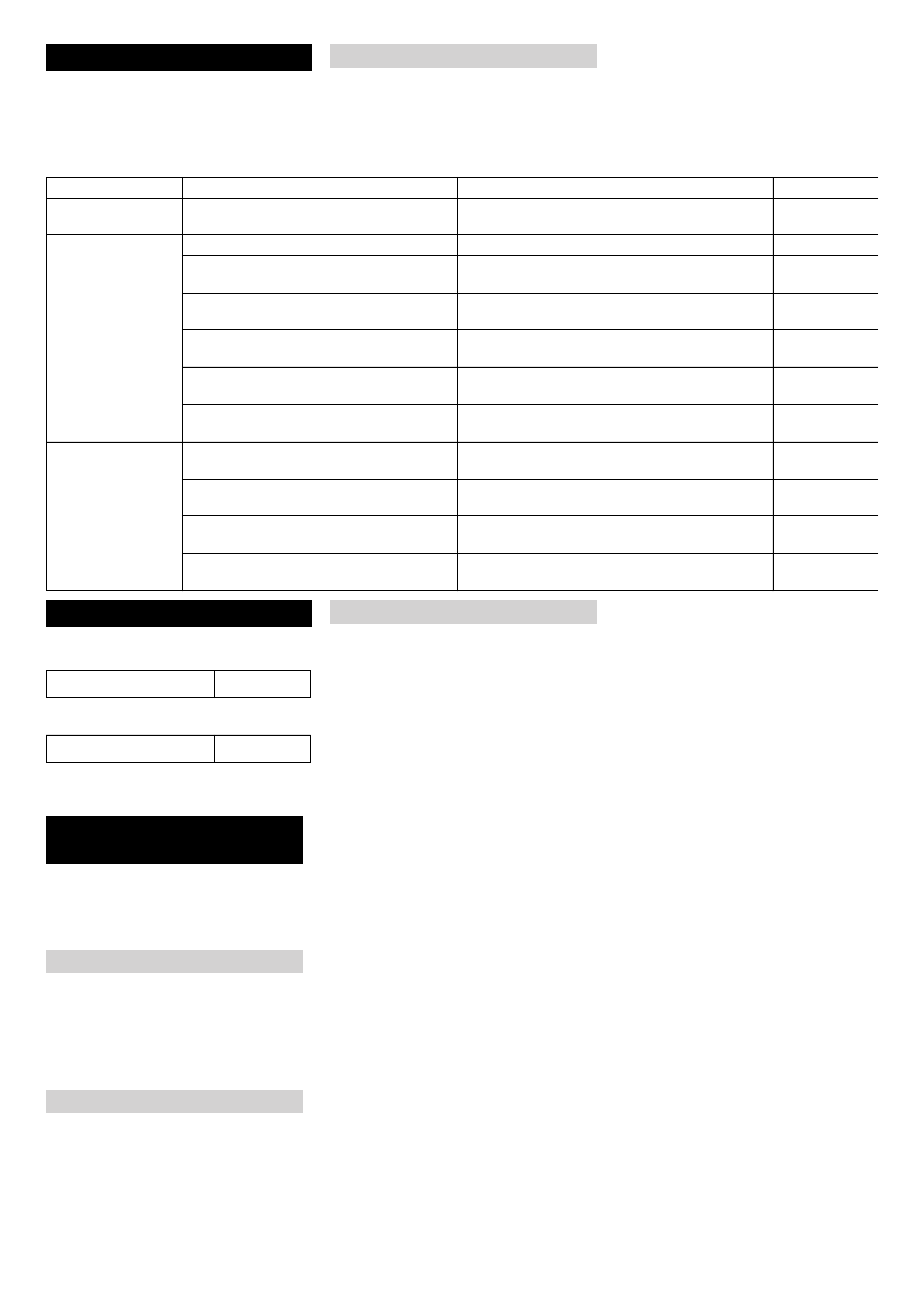

Troubleshooting

Who may remedy faults?

Fault

Possible cause

Remedy

By whom

Plant out of order

Power supply to the pump in the building is

interrupted.

Check power supply and ensure proper supply.

Operator

Processed water is

coloured or is foam-

ing too much

Filter pre-tension is not correct.

Adjust the filter pre-tension

Operator

Filter inlay is defective (leaky)

Replacing filter inlay

Operator, Cus-

tomer Service

Sludge collector or pump basin is dirty

Emptying and cleaning the basins

Operator/ Dis-

posal agency

Improper detergents are used in the wash-

ing unit or washing hall

Use compatible detergents; rinse the system, if

necessary

Operator, Cus-

tomer Service

Detergent dosing in the washing unit is too

high

Check detergent dosing; reset, if necessary

Operator, Cus-

tomer Service

Washing place cleaned with incompatible

detergents

Replace water and rinse the basins

Operator

Filter output is too low Filament filter is blocked

Backwash filament filter; replace filter inlay if re-

quired.

Operator

Immersion pump is of lesser dimension

Install a suitable immersion pump (see require-

ments under "Technical Data")

Operator

Immersion pump is blocked, defective

Clean, repair, replace immersion pump

Operator, Cus-

tomer Service

Pipe or valve is leaky, defective, blocked

Check pipes and valves; clean, repair or replace as

required

Operator, Cus-

tomer Service

Accessories

Filter inlay

Order number

5.033-239.0

Attachment set 'Fresh water switching'

Order number

2.641-521.0

Installing the unit (only for

experts)

Preparing the installation place

Unpack the equipment

Water installation

12

EN