ROTHENBERGER ROPOWER 50 R User Manual

Page 29

ENGLISH

25

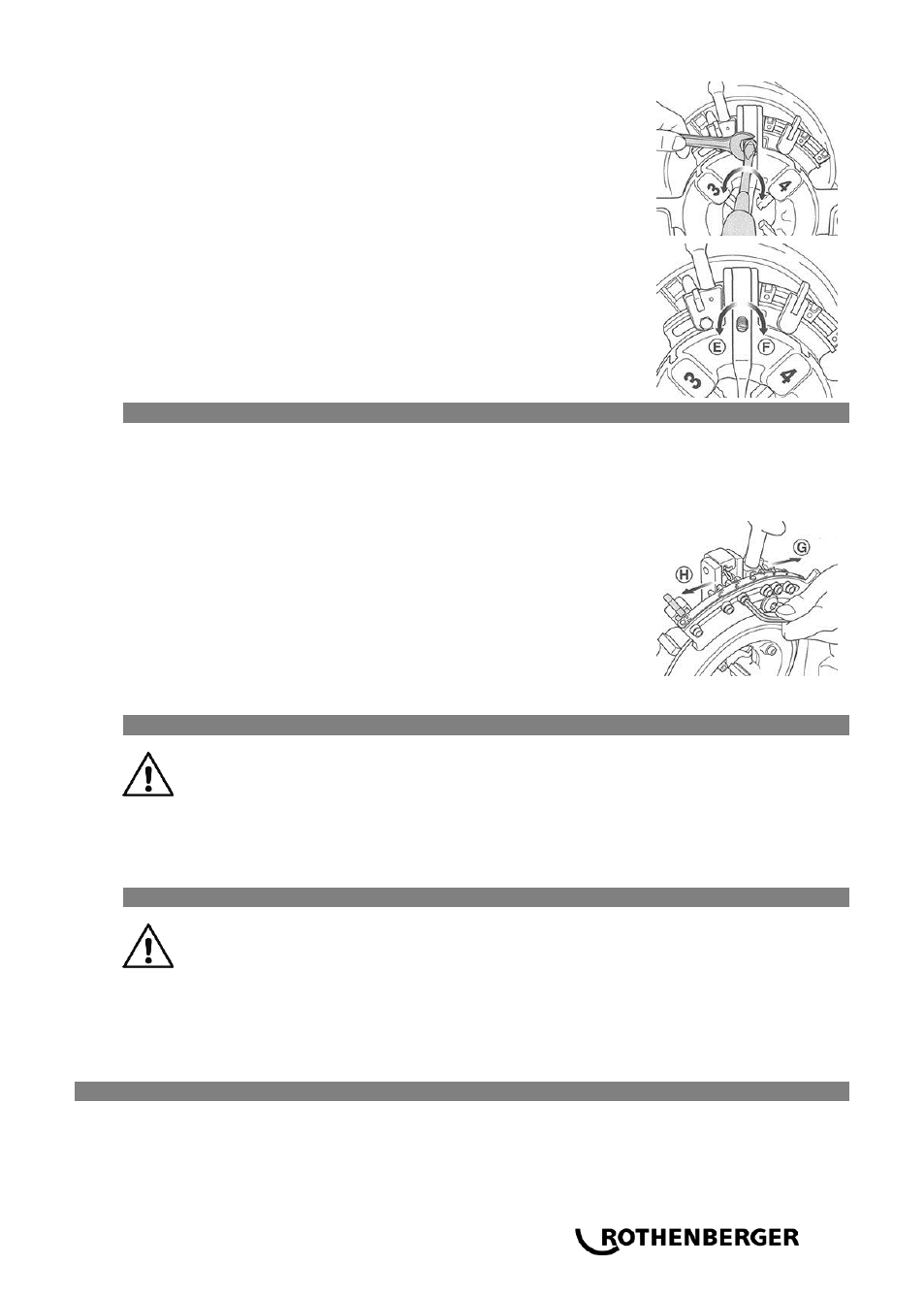

Hold set pin with a slot screwdriver and loosen hex nut.

Turning set pin toward „E“, makes shorter threads and turning

toward „F“ makes longer threads. The thread length will be

changed about 2 mm by half turn.

Hold set pin with a slot screwdriver not to turn it and tighten

hex nut.

5.8

Setting the thread depth

The thread depth of the dies is pre-adjusted as standard at delivery of the threading machine. At

starting with operation of the threading machine the user has to check and control the thread

depth per each thread by using suitable measuring instruments or similar. The correct adjust-

ment has to be done by the user.

Set location plate to location block which is not for the size to

be adjusted.

Loosen the screw and move location block to adjust the thread

depth.

Sliding toward „G“ makes deeper threads and sliding toward

„H“ makes shallower threads The thread depth will change 1,5

to 2 mm threads by one scale.

With the aid of a measuring instrument, check the cut pipe for

a tapered thread etc. and correct the setting if necessary.

5.9

Removing the workpiece

The workpiece is damp and slippery from the thread cutting oil. Carefully en-

sure that it does not slip out of your hands and drop onto your feet when you

remove it from the machine!

Turn the feeder hand wheel clockwise and move back the tool carriage.

Release the clamping chuck.

Release the centring chuck and pull out the workpiece.

5.10

Cleaning after use

Do not remove metal chips using compressed air! There is a risk of eye injuries

and loss of eyesight! Do not pick up sharp-edged metal chips with your bare

hands! Risk of injury! Wear protective gloves!

Remove chips from on and around the machine.

Use a wire brush to remove chips from and clean the clamping chuck, the dies of the die

head and the internal deburrer.

Use a cloth to wipe thread cutting oil splashes from the machine and the workplace.

6

Maintenance and inspection

All machines are subject to natural wear during use.

They must be maintained from time to time and wear parts must be replaced.

This work may only be carried out by an authorised ROTHENBERGER service station. This

gives you a full warranty on the material and workmanship!