Pump operating precautions, Mcres-micro reservoir installation – Swiftech H20 220 ULTIMA XT REV2 User Manual

Page 10

Copyright Swiftech 2010

– All rights reserved – Last revision date: 4-27-10- Information subject to change without notice – URL

Rouchon Industries, Inc., dba Swiftech

– 151 West Victoria Street, Long Beach, CA 90803 – Tel. 310-763-0336 – Fax 310-763-7095 - E Mail: [email protected]

10 of 15

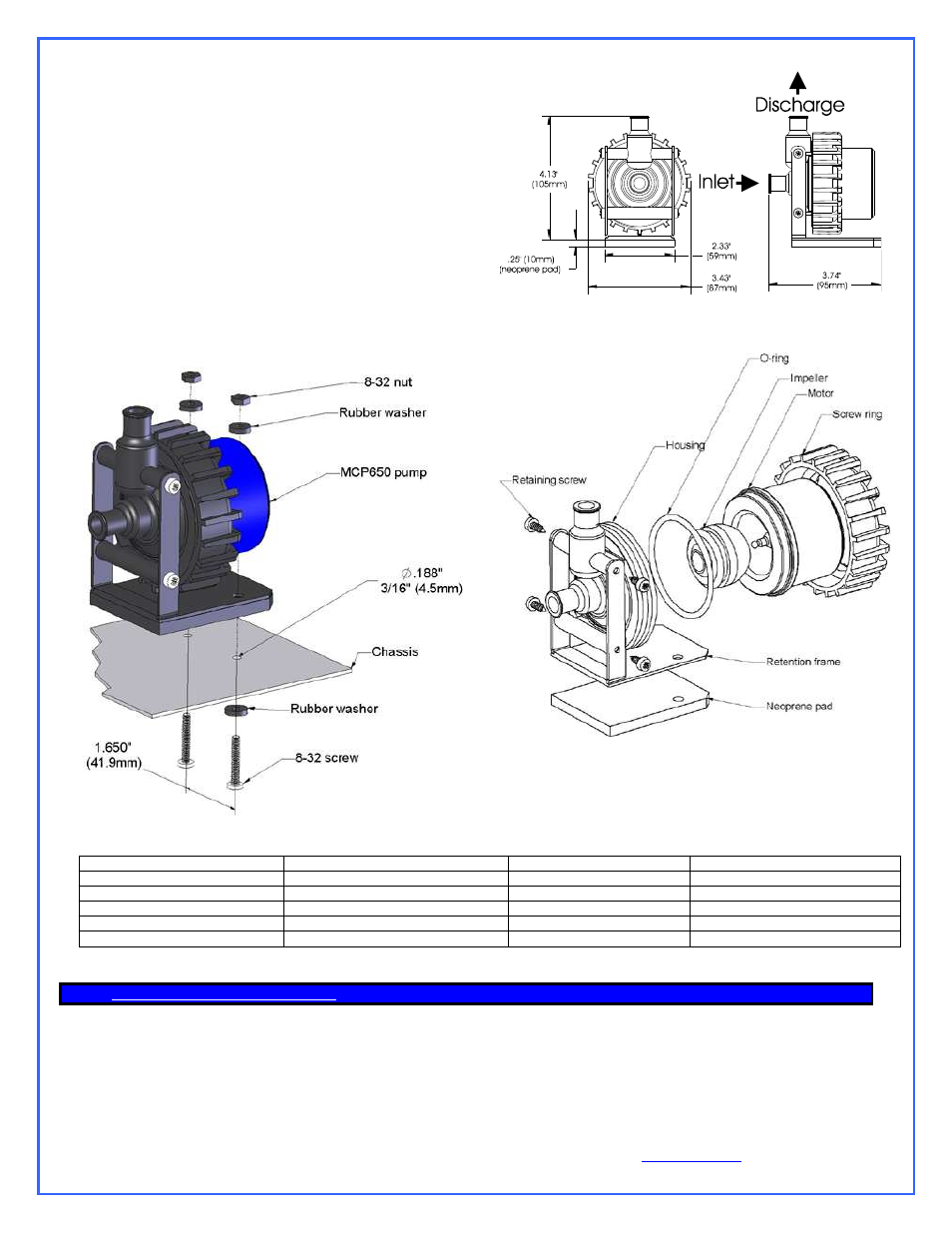

In general, we recommend installation of the pump at the bottom of

the chassis.

The base of the pump features a soft neoprene pad coated with

strong adhesive material. Once the final location for the pump has

been determined, simply peel-

off the pad’s protective paper, and press

the pump against the chassis surface. The surface should be clean,

and non greasy. Thru-bolts are also provided for permanent

installation, and require drilling holes in the chassis.

Pump operating precautions:

The MCP655-B pump should never be run dry, even for a quick test

.

You should always prime the pump with fluid before you start operating it

(see warranty note *).

Use of coloring die or fluorescent additives

containing particulate fillers

will cause excessive wear to the pump’s impeller bearing (see warranty

note **).

Note 1: Always make sure to directly connect the RESERVOIR

DISCHARGE to the PUMP INLET.

Permanent installation to the chassis, and exploded view

4.

MCRES-M

ICRO RESERVOIR

I

NSTALLATION

Nominal voltage / Connector

12 V DC / Molex 4 pin

Maximum pressure

50 PSI (3.5 BAR)

Operating voltage range

8 to 24 VDC

Maximum head

10 ft (3.1 m)

Nominal current (@ 12 V)

2 amps

Maximum discharge

~ 317 GPH (1200 LPH)

Nominal power (@ 12 V)

24 W

Temperature range

32 °F to 140°F (0 °C to 60 °C)

Motor type

Brushless, microprocessor controlled

Weight

1.4 LB (650 gr.)

Impeller Housing material

Noryl®

Connection size

½" barbs