Parts list – Swiftech QPOWER User Manual

Page 5

Swiftech Inc., 1703 E. 28

th

St., Signal Hill, CA 90755 T. (562) 595-8009 F. (562) 595-8769

- 5 -

Parts list

Parts

AMD

INTEL

QTY

PARTS

AMD

INTEL

QTY

Water-block

Common to both

1

6-32 Lock-nuts

Common to both

4

6-32 x 1 ½” screws (for HS)

Common to both

4

Black fiber washers

X

8

Standoffs

Common to both

4

Thermal grease

Common to both

1

Springs

Common to both

4

Tube insert

Common to both

2

.230x.096 Nylon spacers

X

8

P4 brackets

X

2

.220x.046 Nylon spacers

X

4

4-40 socket screws

X

4

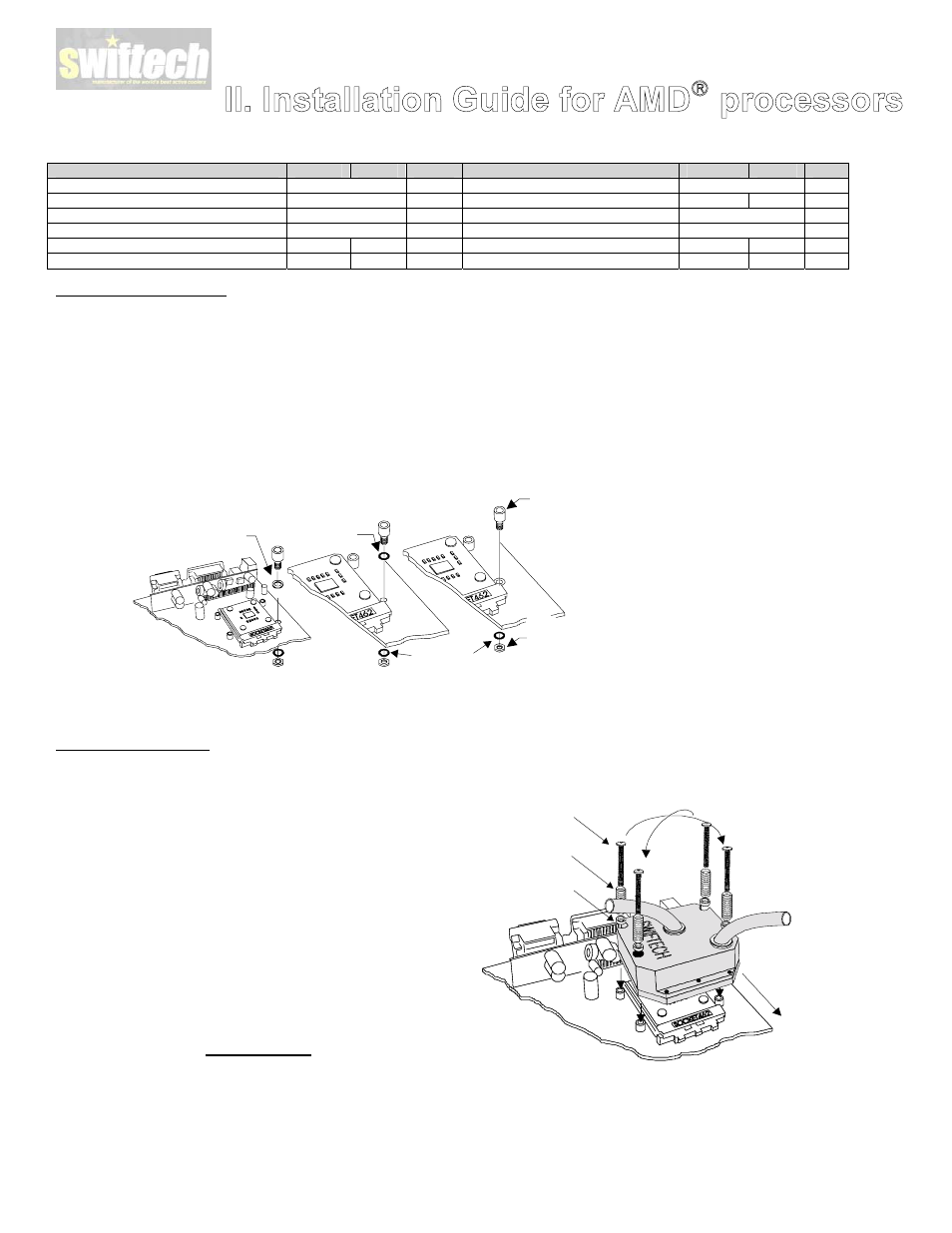

I. Preparing the motherboard

•

Install standoffs in MB

Determine which standoff washers to use, depending on your MB mounting holes:

o

Large holes .230”(5.8mm) diameter : use .220x.046 Nylon spacers. The washers fit inside the MB hole.

o

Small grounded holes .150”(3.8mm) diameter: you can recognize grounding by a silver ring around the holes; no washers needed nor

necessary.

o

Small holes, NOT grounded (bare circuit board): you must use black fiber washers, or damage to the MB may occur.

MB with

large holes

MB with

small holes,

NOT grounded

MB with

small holes,

grounded

Use .220x.046

nylon spacer

(fit inside the hole)

Use black

Fiber washer

No washer

necessary

Standoff

Lock-nut

on back side of

the MB

Fiber washer

Fiber washer

Install standoff in each one of the four holes

surrounding the socket. Keep the standoff &

washer centered over the MB holes, and secure

with a fiber washer and lock-nut on backside of

the MB.

•

Re-install the MB inside the case.

II. Water-block installation

•

The case should be laying flat on a table.

•

Insert the processor into the socket, and lightly coat the

processor core with the included high quality thermal

compound (Arctic Alumina). Only a paper-thin coat is

necessary. It should be applied using preferably a razor blade,

or a credit card, held between thumb and index at a 45-degree

angle. It is critical to ascertain that the entire core is covered

with a uniform coat of thermal compound.

•

Prepare 4 assemblies composed of a 1 ½” screw, 1 nylon

spacer, and 1 spring as shown in Figure 2. Drop each

assembly into the MCW462-U mounting holes.

•

Install the MCW462-U block on the CPU. The copper base of

the MCW462-U features a large step for clearance with the

socket cam box. Make sure to respect this orientation. Keep

the heat sink mounting holes lined up with the standoffs. Avoid

twisting the block to prevent smearing the thermal compound.

•

Gradually tighten the screws in a crisscross pattern until you

feel that they reach the bottom of the standoff. A “finger-tight”

lock is sufficient. Adjustments such as tightening the screws

only partially are strictly prohibited. Such attempts will result

in improper contact between the CPU core and the heat sink,

and result in CPU overheating.

Large step side

over cam box

Crisscros

tightening

pattern

1 1/2“ Philips

screw

Spring

.230x.096

Nylon spacer