Installation – Blodgett SC-E Series User Manual

Page 9

OM-SC-E 7

A. Electrical Supply Connection

1. Access for Connection, Panel Removal

Open the wiring and control panel by removing screws from the front

panel. Lift the panel, and swing its bottom toward you. Set the panel aside.

2. Supply Voltage

The unit must be operated at the rated nameplate voltage. A temporary

fluctuation of plus or minus 10 percent is acceptable.

3. Phase Selection

Refer to the steamer schematic (at the back of this manual) for wiring

information.

4. Terminal Block

The terminal block for incoming power is located at the back of the control

compartment. The ground terminal is located in the wiring compartment

next to the terminal block. The unit must have a separate ground wire for

safe operation. Minimum size for the ground wire is 10 AWG.

5. Supply Wire

To determine the type of wire you need for the power supply, find the

operating voltage and number of phases on the unit data plate. Refer to the

table provided on the next page or to the label on the unit’s back for the

correct wire size and insulation temperature rating. The “Electrical Supply

Connection” label inside the unit gives directions for proper connection

of the terminal block jumpers. The wire specified has to be used, or the

unit will not meet Underwriters Laboratories and National Electrical Code

requirements.

6. Branch Circuit Protection

Each conductor must have over-current protection. Refer to the label on

the back of the unit for the proper wire type and size. Connections to the

unit must be watertight. We strongly recommend that the steamer have its

own branch circuit protection. Current and power demands for the different

units are as follows:

WARNING

THE UNIT MUST BE INSTALLED BY

PERSONNEL WHO ARE QUALIFIED TO

WORK WITH ELECTRICITY AND PLUMBING.

IMPROPER INSTALLATION CAN CAUSE

INJURY TO PERSONNEL AND/OR DAMAGE

TO THE EQUIPMENT. THE UNIT MUST BE

INSTALLED IN ACCORDANCE WITH

APPLICABLE CODES.

CAUTION

DO NOT INSTALL THE UNIT WITH THE RIGHT

SIDE VENTS BLOCKED OR WITHIN 12 INCHES

OF A HEAT SOURCE (LIKE A BRAISING PAN,

DEEP FRYER, CHAR BROILER, OR KETTLE).

TO AVOID DRAIN PROBLEMS, LEVEL THE

UNIT FRONT TO BACK.

Installation

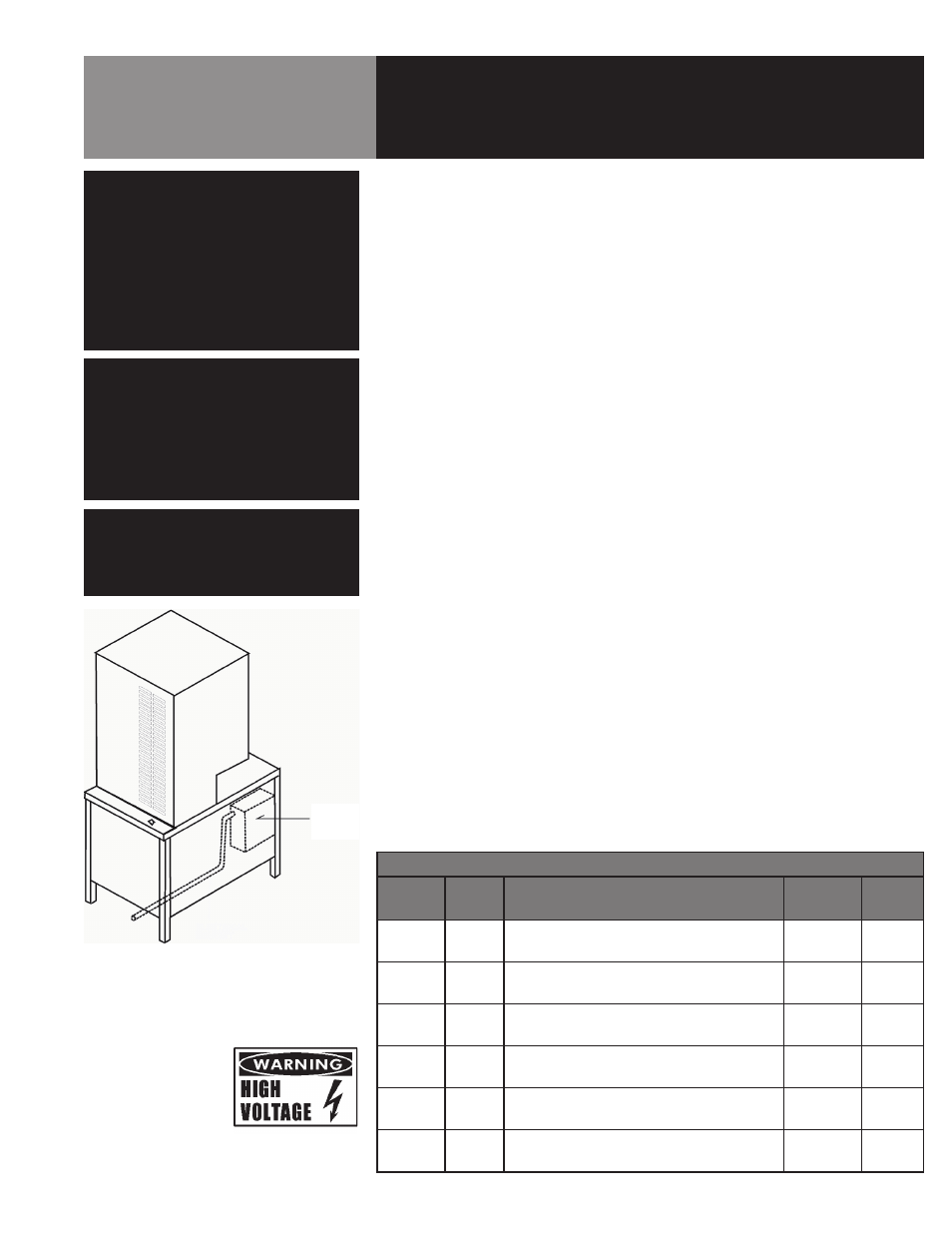

Control

Box

UNIT

FRONT

The knockout hole is sized for a one inch

conduit fitting. Pass the wire up the back

through this knockout hole to the front. Make

the connections from the front.

WARNING

TO AVOID DAMAGE OR INJURY, FOLLOW THE

ELECTRICAL SCHEMATIC EXACTLY WHEN

CONNECTING THE UNIT.

ELECTRICAL SUPPLY CONNECTIONS

VOLTAGE PHASE

WIRING REQUIRED

MAXIMUM

CURRENT

POWER

208

1

#2 AWG copper only, at least 75

°C

#3 AWG copper only, at least 90

°C

92 AMP

19 Kw

208

3

#4 AWG copper only, at least 75

°C

#6 AWG copper only, at least 90

°C

53 AMP

19 Kw

240

1

#3 AWG copper only, at least 75

°C

#4 AWG copper only, at least 90

°C

80 AMP

19 Kw

240

3

#6 AWG copper only, at least 75

°C

#8 AWG copper only, at least 90

°C

46 AMP

19 Kw

480

3

#10 AWG copper only, at least 75

°C

#10 AWG copper only, at least 90

°C

23 AMP

19 Kw

480

1

#10 AWG copper only, at least 75

°C

#10 AWG copper only, at least 90

°C

40 AMP

19 Kw