Inspection, installation and transporting – U.S. Products TREADMASTER User Manual

Page 19

13 - TreadMaster Information and Operating Instructions

EN

INSPECTION, INSTALLATION AND

TRANSPORTING

INSPECTING ASSEMBLIES

After receiving your TreadMaster, carefully unpack the boxes and inspect the housing

assembly, brush and head assembly for shipping damage.

No matter which TreadMaster configuration you order (see Table 1 and Table 2 on

34), you can receive up to three major assemblies in your shipment unless you specify

otherwise:

1. Soft Brush for Painted Escalators

2. Housing Assembly

3. Head Assembly

Each machine is tested and inspected before being shipped. Any shipping damage incurred

is the responsibility of the carrier. You should notify the carrier immediately if you notice

damage to the box, to the machine or any parts.

INSTALLING NEW HEAD ASSEMBLY

For the initial setup, install the head assembly by:

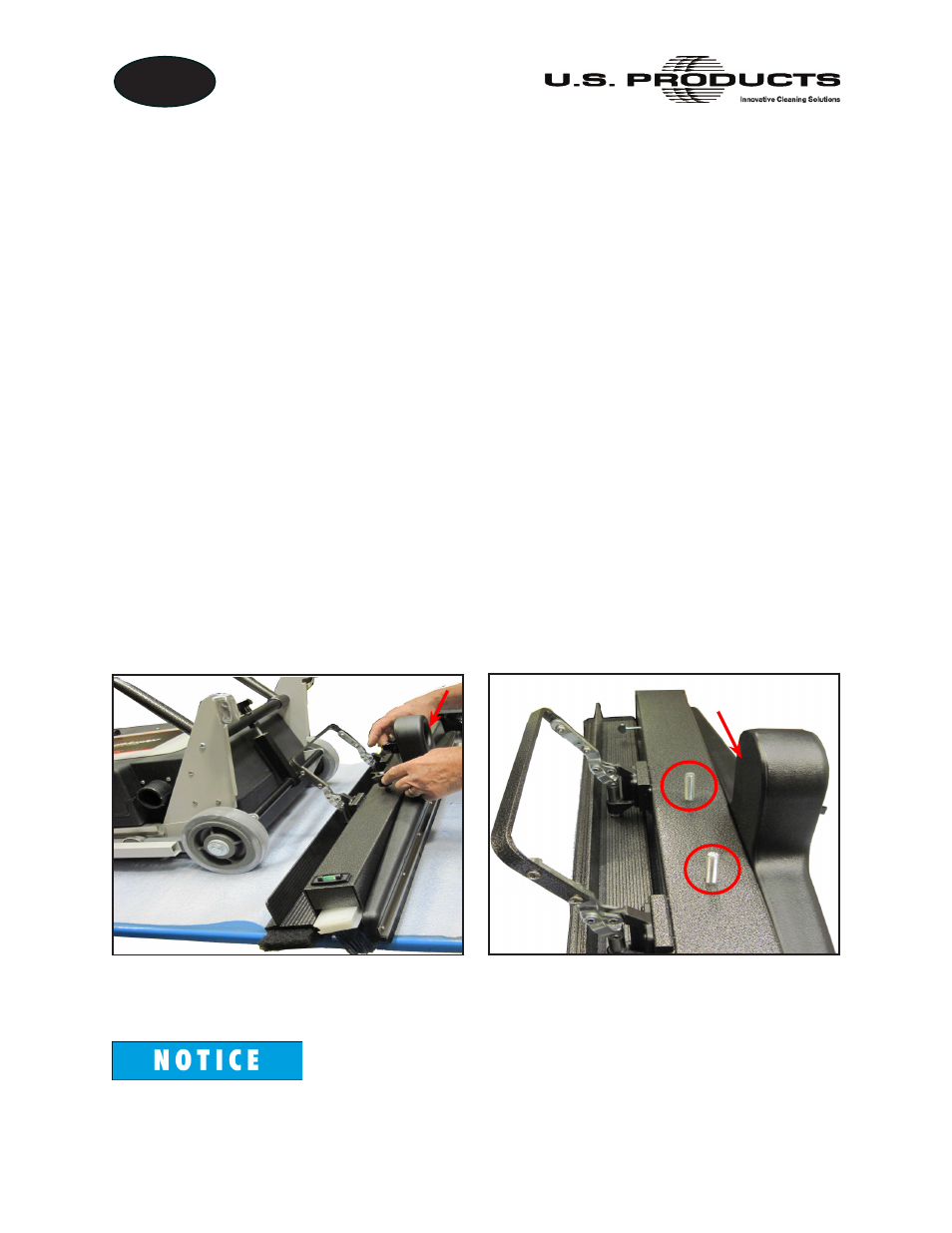

1. Placing the head assembly and housing assembly on a flat surface (see Figure 2).

2. Unfastening the two fluted knobs on the head assembly (see Figure 2 and Figure 3).

Note that the nozzle opening is facing outward during installation.

Figure 2. Position Assemblies

Together, on Flat Surface

Figure 3. Fluted Knobs Removed

from Head Assembly; Nozzle Facing

Outward

Nozzle