Double wheel pivot installation (mbzm0002), Connector exit orientation adjustment – Red Lion ZMH - HEAVY DUTY User Manual

Page 4

4

LIMITED WARRANTY

The Company warrants the products it manufactures against defects in materials and workmanship

for a period limited to two years from the date of shipment, provided the products have been stored,

handled, installed, and used under proper conditions. The Company’s liability under this limited

warranty shall extend only to the repair or replacement of a defective product, at The Company’s

option. The Company disclaims all liability for any affirmation, promise or representation with

respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against

damages, claims, and expenses arising out of subsequent sales of RLC products or products

containing components manufactured by RLC and based upon personal injuries, deaths, property

damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be

to any extent liable, including without limitation penalties imposed by the Consumer Product Safety

Act (P.L. 92-573) and liability imposed upon any person pursuant to the Magnuson-Moss Warranty

Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except

those expressly contained herein. The Customer acknowledges the disclaimers and limitations

contained herein and relies on no other warranties or affirmations.

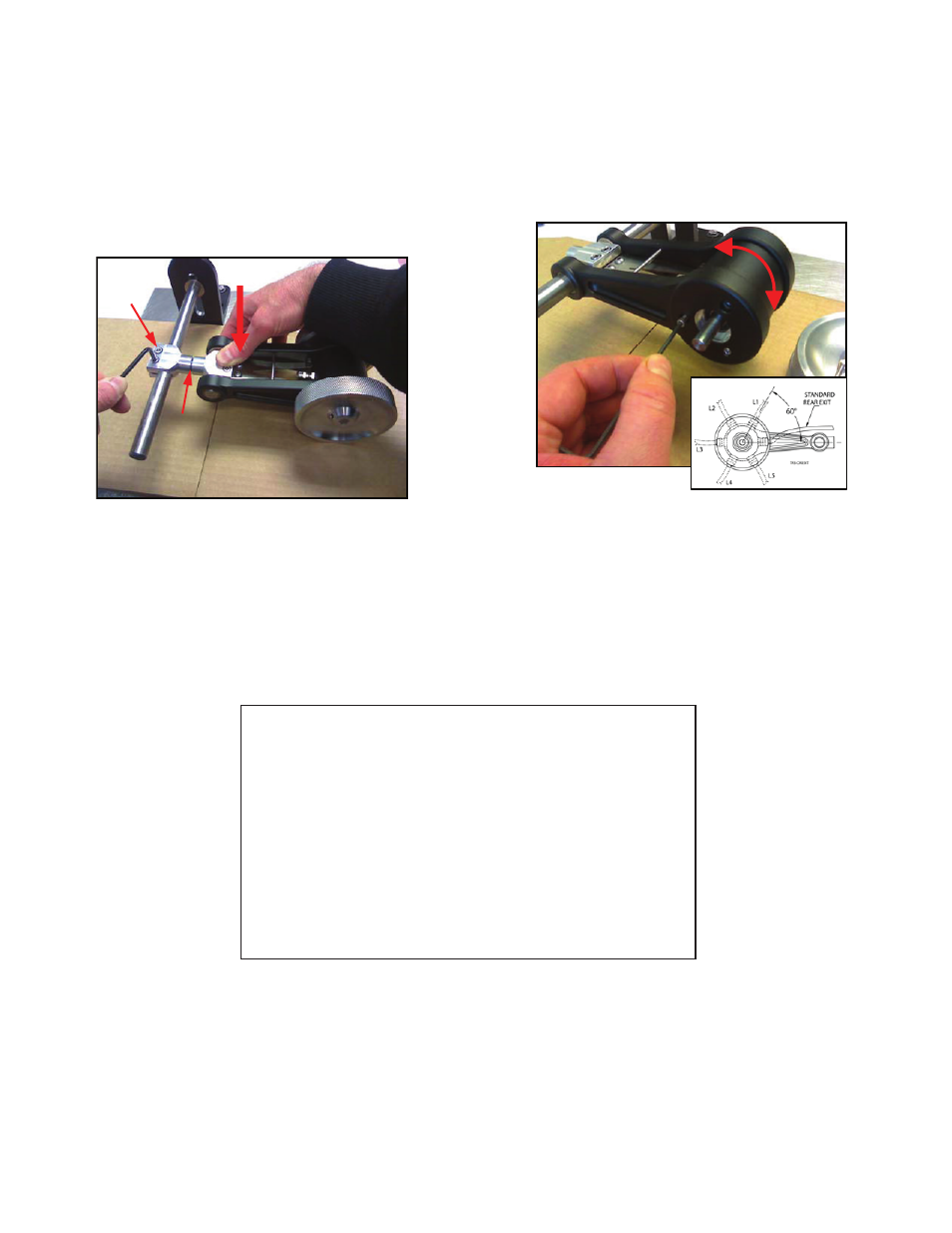

DOUBLE WHEEL PIVOT INSTALLATION

(MBZM0002):

Note: It is recommended that double wheel ZMH’s be installed with the optional

Double Wheel Pivot. The pivot allows the unit to rotate freely to maintain

equal pressure on both wheels, accommodating uneven/angled surfaces and

mounting misalignment.

1. Thread the pivot clamp into the end of the ZMH’s clamp by hand until the

threads just bottom out then back out approximately 1 revolution to allow for

rotation after installation.

2. Slide the pivot clamp over a fixed Ш5/8" (Ш0.625 +0/-0.005") shaft. The

optional ZMH Mounting Bracket (MBZM0001) is shown in the picture.

3. While applying a load to the spring, securely tighten the two clamp bolts with

a 5/32" (supplied) or 4mm hex “L” key.

CONNECTOR EXIT ORIENTATION ADJUSTMENT:

1. Slide the ZMH over a Ш5/8" (Ш0.625 +0/-0.005") shaft and tighten the clamp

bolts with the supplied 5/32" hex “L” key.

2. Remove the measuring wheel(s) using the supplied 3/32" hex “L” wrench to

loosen the set screws.

3. Remove 6 screws (3 on each side) from the side plates using the supplied

7/64" hex “L” key.

4. Rotate body of encoder to desired orientation, aligning bolt pattern with one

of six unique positions (see inset drawing).

5. Replace side plate screws and measuring wheel(s), making sure to tighten

screws securely.

Apply Load

Pivot

Clamp

Threaded

Joint

Rotate

Body

Red Lion Controls

Headquarters

20 Willow Springs Circle

York PA 17406

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

Red Lion Controls

China

Unit 302, XinAn Plaza

Building 13, No.99 Tianzhou Road

ShangHai, P.R. China 200223

Tel +86 21 6113 3688

Fax +86 21 6113 3683

Red Lion Controls

Europe

Softwareweg 9

NL - 3821 BN Amersfoort

Tel +31 (0) 334 723 225

Fax +31 (0) 334 893 793

Red Lion Controls

India

201-B, 2nd Floor, Park Centra

Opp 32 Mile Stone, Sector-30

Gurgaon-122002 Haryana, India

Tel +91 984 487 0503