Mot or drive, Ordering information follower mode application, Mo tor – Red Lion MDC User Manual

Page 4: Master mode application, Operator access, User settings, Program diagnostics, Program security

4

OPERATOR ACCESS

This is used with the program disable DIP switch or an external user input

that is selected for the program disable function. When a setpoint is selected as

NO, it can be viewed, but NOT changed from the front panel keypad. The

following setpoint values can be disabled from front panel access programming:

Speed/Ratio Setpoint 1 and 2

Jog Speed

Ramp Rate 1 and 2

Jog Ramp

Alarm Setpoint 1 and 2

Gain

Setpoint Scroll Menu

USER SETTINGS

The operator can reset ALL parameters to the factory settings if desired.

PROGRAM DIAGNOSTICS

This allows testing of the various MDC inputs and outputs. It is especially

useful after unit installation to independently test the operation of external

switches, relays, the feedback transducer, and the motor drive system.

Inputs - The MDC displays an alphanumeric character to indicate a Dedicated

Function Input or a User Input is active. This allows the user to check switch

operation and wiring connections to the Inputs.

Alarm Outputs - The up and down arrow keys are used to select an alarm

output and set it to the active or inactive state. This allows the user to check

the operation of devices wired to the alarm outputs and the wiring

connections.

Drive Output - This function allows the user to test the Drive System. A %

Output value is entered through the front panel keypad causing the motor to

run at the corresponding open loop speed. The display indicates the motor’s

feedback frequency.

PROGRAM SECURITY

The programmable code number is used in conjunction with the program

disable DIP switch and/or a user input programmed for the program disable

function to limit operator access to programming.

ORDERING INFORMATION

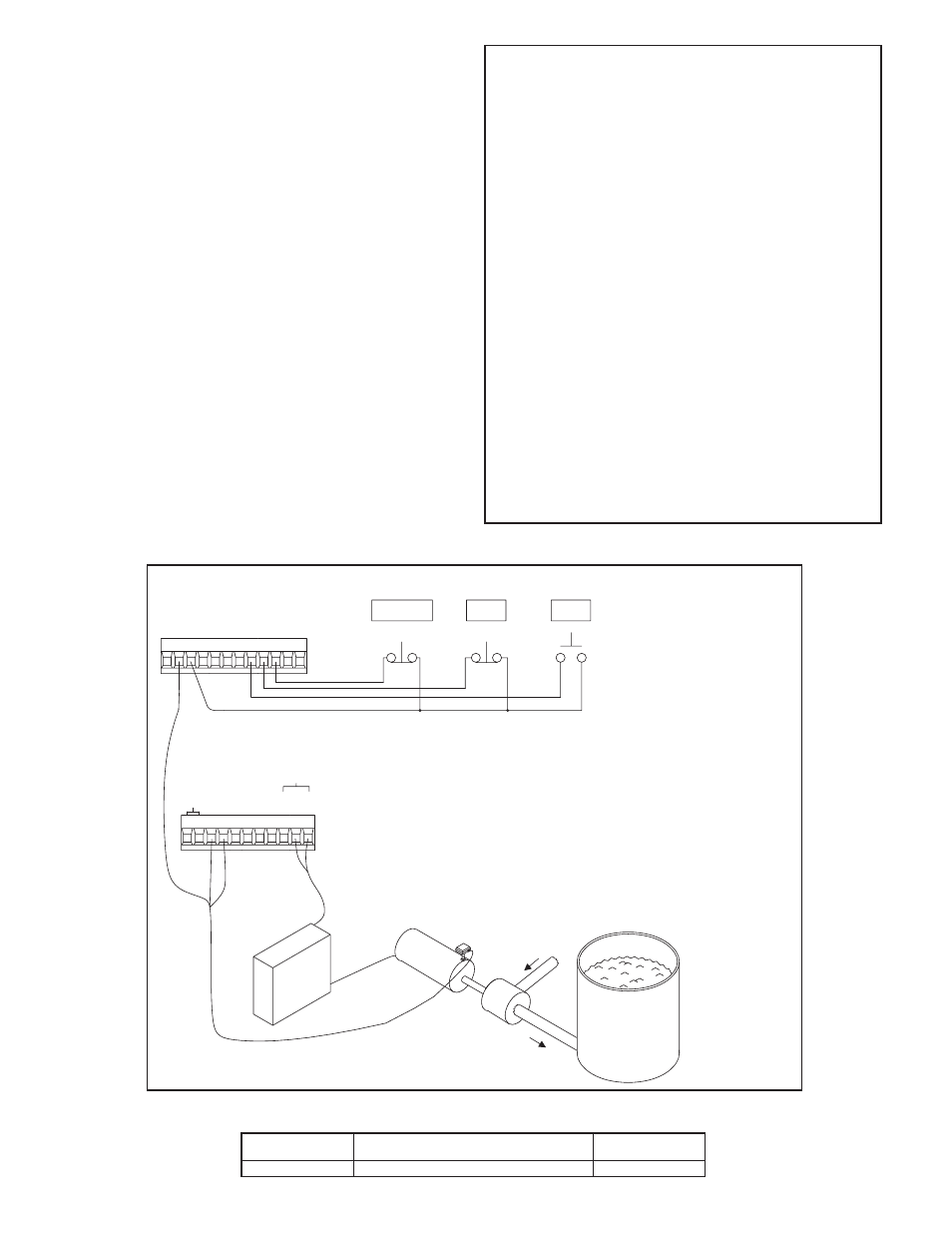

FOLLOWER MODE APPLICATION

A fertilizer production facility is mixing pellets containing Nitrogen with

pellets that contain Phosphorus. A chemical ratio of 1:1 is determined by the

speed of two different conveyors. Because of differences in the gearing of

the conveyor and concentration of the pellets, the Nitrogen conveyor motor

must run at 3 times the speed of the Phosphorus conveyor motor in order to

produce a 1:1 mixture. The maximum speed of both motors is 2000 RPM.

Set the follower MDC scaling to produce a 1:1 mixture of Nitrogen and

Phosphorus when a setpoint of 1.0000 is entered. Display speed units are in

RPM’s. Both the lead and feedback frequency are taken from 60 tooth gears

on each motor shaft.

1) Choose the Phosphorus conveyor motor for the follower MDC. It runs

slower than the Nitrogen conveyor motor.

2) Set the Pulses per revolution feedback to 60.

3) Set the MAX RPM feedback to 2000. This is the conveyor motor’s

maximum operating speed.

4) Set display decimal point to 0.

5) Set display unit to 2000. The display speed unit maximum is 2000 at a

MAX RPM FB of 2000. If the display units wanted were conveyor feet/

minute or Phosphorus pellets in lbs/sec, the equivalent display value for

2000 RPM would be entered.

6) Set the pulses per revolution lead to 60.

7) Setting the MAX RPM Lead:

This is the Lead RPM that would be necessary to have a 1:1 mixture if

the Follower Speed was MAX RPM FB (2000 RPM). Since the Nitrogen

conveyor motor must run 3 times as fast as the Phosphorus motor, MAX

RPM LD = 3 * 2000 = 6000 RPM. Set MAX RPM LD = 6000 RPM. This

is the correct value, even though the Nitrogen conveyor motor would never

actually run at 6000 RPM. A ratio setpoint of 1.0000 on the MDC is now

equal to a 1:1 mixture of Phosphorus and Nitrogen.

OPEN LOOP

JO

G

F-ST

OP

R-ST

OP

RUN

USR.IN

P.

4

USR.IN

P.

3

USR.IN

P.

2

COMM.

FEEDBACK IN

P

LEAD IN

P

4

3

2

1

12

11

10

9

8

7

6

5

-

+

RE

F.

COMM.

DRIVE ENABLE OU

T

AL-2 SN

K

RE

D

AL-1 SN

K

COMM.

+12VDC OU

T

LABEL

)

(SEE SIDE

AC PW

R

10 11

6 7 8 9

4

3

2

1

5

ISOL

AT

ED

DRIVE OUTPUT

USR.IN

P.

1

MO

TOR

WHITE

BLAC

K

EMERGENCY

STOP

STOP

MOTOR

START

MOTOR

MOT

OR

DRIVE

MASTER MODE APPLICATION

A pump delivers a maximum of 30.0 gallons per minute with a shaft speed of

1750 RPM. A shaft pulse encoder generates 60 pulses/revolution. Set the MDC

scaling to control and display pumping speed in tenths of a gallon/minute. In the

Program Scaling Module:

1) Set the pulses per revolution feedback to 60.

2) Set the maximum RPM feedback to 1750. This is the pump shaft’s maximum

operating speed.

3) Set display decimal point to 0.0. Display units are in 0.1 gpm.

4) Set max display units to 30.0. The display speed unit maximum is 30.0 at a MAX

RPM FB of 1750.

MODEL NO.

DESCRIPTION

PART NUMBERS

115/230VAC

MDC

Motor Drive Controller with Red Backlighting

MDC00100