Description (cont’d), Safety summary, Specifications – Red Lion MDC User Manual

Page 2: Programming

2

DESCRIPTION (Cont’d)

The unit is factory configured for an isolated 0 to 10 VDC drive output

signal. The output drive signal can be adjusted to span from 0 to 15 VDC via an

accessible potentiometer. The drive output is jumper selectable for an external

reference. To use the external reference, the MDC is connected to the drive in

place of an external potentiometer.

The Motor Drive Controller has a light weight, high impact plastic case with a

clear viewing window. The sealed front panel meets NEMA 4X/IP65 specifications

for wash-down and/or dusty environments, when properly installed. Plug-in style

terminal blocks simplify installation and wiring change-outs.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Do not use this unit to directly command motors, valves, or other actuators

not equipped with safeguards. To do so, can be potentially harmful to persons

or equipment in the event of a fault to the unit.

SPECIFICATIONS:

1. DISPLAY: 2x8, 0.3" (7 mm) high characters, negative image transmissive

LCD, with red LED backlighting.

2. POWER: 115/230 VAC ±10%, 50/60 Hz, 10 VA, switch selectable.

3. MEMORY: Non-volatile E

2

PROM retains all programming information and

values when power is removed or interrupted.

Power Cycles(ON/OFF): 100,000 min.

Data Retention: 10 years min.

4. SENSOR POWER: +12 VDC ±25% @ 100 mA.

5. INPUTS (LEAD AND FEEDBACK): DIP Switch selectable to accept input

pulses from a variety of sources including outputs from CMOS or TTL

circuits and all standard RLC sensors.

Input Freq:

1 Hz to 20 KHz (Master Mode), 1 Hz to 12 KHz (Follower Mode).

Logic: Input trigger levels V

IL

= 1.5 V

MAX

; V

IH

= 3.75 V

MIN

.

Current Sinking: Internal 7.8 KΩ pull-up to +12 VDC, I

MAX

= 1.6 mA.

Current Sourcing: Internal 3.9 KΩ pull-down, 7.3 mA @ 28 VDC

MAX

.

Magnetic Pickup:

Sensitivity: 200 mV PEAK.

Hysteresis: 100 mV.

Input impedance: 3.9 KΩ @ 60 Hz.

Maximum input voltage: ±50 V PEAK.

Note: For magnetic pickup input, the Sink/Source DIP switch must be in the

SRC position.

6. CONTROL LOOP RESPONSE: 10 msec (Master Mode), 20 msec

(Follower Mode).

7. CONTROL ACCURACY:

0.01% of Speed Setpoint (Master Mode)

0.02% of Ratio Setpoint (Follower Mode)

Minimum Frequency Resolution: 0.00125 Hz

8. ERROR TRIM: ±4095 BITS.

9. ERROR GAIN: 0 to 99%.

10. RAMP RATE: (Ramp 1, Ramp 2, and Jog Ramp)

1 Hz to 20 KHz/sec, set in user units/sec.

0.0001 to 1.9999 ratio units/sec (Ramp 1 & 2 in Follower Mode).

11. CONTROL INPUTS:

Internal 10 KΩ pull-up to +5 VDC. V

IL

= 1.0 V

MAX

, V

IH

= 4.0 V

MIN

.

Response time = 10 msec nominal, 30 msec max.

INPUTS

SWITCH CONNECTIONS

RUN

Momentary N.O.

FAST STOP

Momentary N.C.

RAMP STOP

Momentary N.C.

JOG

Sustained N.O.

OPEN LOOP

Maintained

USER INPUTS(4)

Function Specific

12. OUTPUTS:

Drive Enable, Alarm 1, and Alarm 2:

Solid state, current sinking NPN Open collector transistor.

V

CE

= 1.1 V

SAT

@ 100 mA max.,

V

OH

= 30 VDC max.

(Internal zener diode protection.)

Response Time:

Drive Enable: 10 msec nominal; 30 msec max.

Alarm 1&2: Programmable

Normal: 1 sec nominal, 2 sec max.

Fast: 20 msec nominal, 40 msec max.

Isolated Drive Output: Jumper selectable internal/external reference 5 mA max.

Internal Reference: Pot adjustable from 0 to 5 VDC min. through 0 to 15

VDC max. span.

External Reference: 15 VDC max. (positive polarity only).

Isolation: 2300 Vrms for 1 minute

250 V working

13. ENVIRONMENTAL CONDITIONS:

Operating Temperature: 0 to 50°C

Storage Temperature: -40 to 70°C

Operating and Storage Humidity: 85% max. RH (non-condensing) from

0°C to 50°C.

Altitude: Up to 2000 meters

14. CONSTRUCTION: High impact plastic case with clear viewing window.

The front panel meets NEMA4 X/IP65 requirements for indoor use when

properly installed. Installation Category II, Pollution Degree 2. Panel gasket

and mounting clips included.

15. WEIGHT: 1.5 lbs. (0.68 Kg).

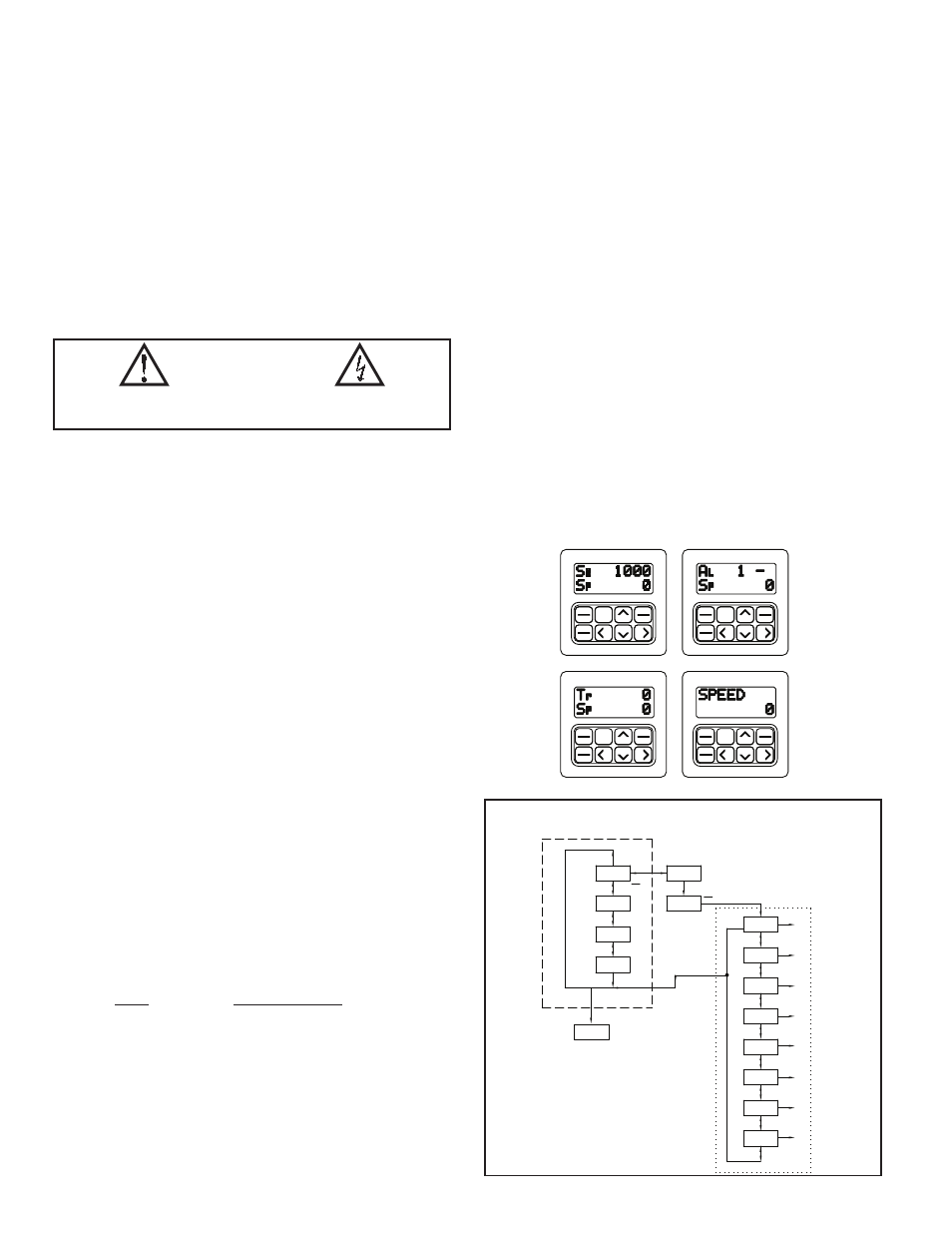

PROGRAMMING

Programming the MDC unit is accomplished through the front panel keypad,

which allows the user to enter into Main Menus, Sub-Menus, and Edit Menus.

The English language prompts, the flashing parameter values, and the front panel

keypad aid the operator during programming. In the normal run mode, the main

display loop allows the user to scroll through the four programmable indication

displays, using the direction keys. From the main loop, setpoints, alarm values

and a gain value may be accessed directly for changes, without entering the

programming loop. All other parameters are accessed through the pro-gramming

loop, which can be set to require an access code number for loop entry. In the

programming loop, parameters can be viewed or changed and the operator can

exit anywhere in the loop.

SET

PGM

ENT

RUN

F1

SEL

ESC

F2

STP

STP

F2

ESC

SEL

F1

RUN

ENT

PGM

SET

STP

F2

ESC

SEL

F1

RUN

ENT

PGM

SET

STP

F2

ESC

SEL

F1

RUN

ENT

PGM

SET

102

Sp

RUN

- -

Sp

500

p

S

1 1

>

>

>

>

>

>

>

ENT

PGM

ENT

ALARMS

4

3

2

1

0

** *

>

>

>

>

>

>

>

>

SET

ESC

<

>

PGM

>

>

>

>>

>

>

>

>

SEL

>

SEL

>

SEL

>

SEL

>

SEL

>

SEL

>

SEL

>

SEL

>

SEL

OPTIONS

SECURITY

PROGRAM

DIAGNOST

PROGRAM

DISPLAY

PROGRAM

PROGRAM

USER

PROGRAM

PROGRAM

SCALING

PROGRAM

MODE

MASTER

0000

PRO.CODE

500

Tr

PROGRAM

MODE

AL

S R

500

500

SPEED

USER

SETPOINTS

>

>

*** - ACTIVE ONLY WHEN THE PROGRAM

DISABLE FUNCTION IS ENABLED.

1-4 - THE FOUR INDICATION DISPLAYS

--DASHED LINE:

MAIN DISPLAY LOOP

... DOTTED LINE:

PROGRAMMING LOOP

<

ESC

INDICATION DISPLAY

PROGRAMMING

MODULE

MODULE

CAUTION: Risk of Danger.

Read complete instructions prior to

installation and operation of the unit.

CAUTION: Risk of electric shock.