Iring, Eter, Nstalling – Red Lion PAXLTC User Manual

Page 4

4

2.0 W

IRING

THE

M

ETER

1.0 I

NSTALLING

THE

M

ETER

Installation

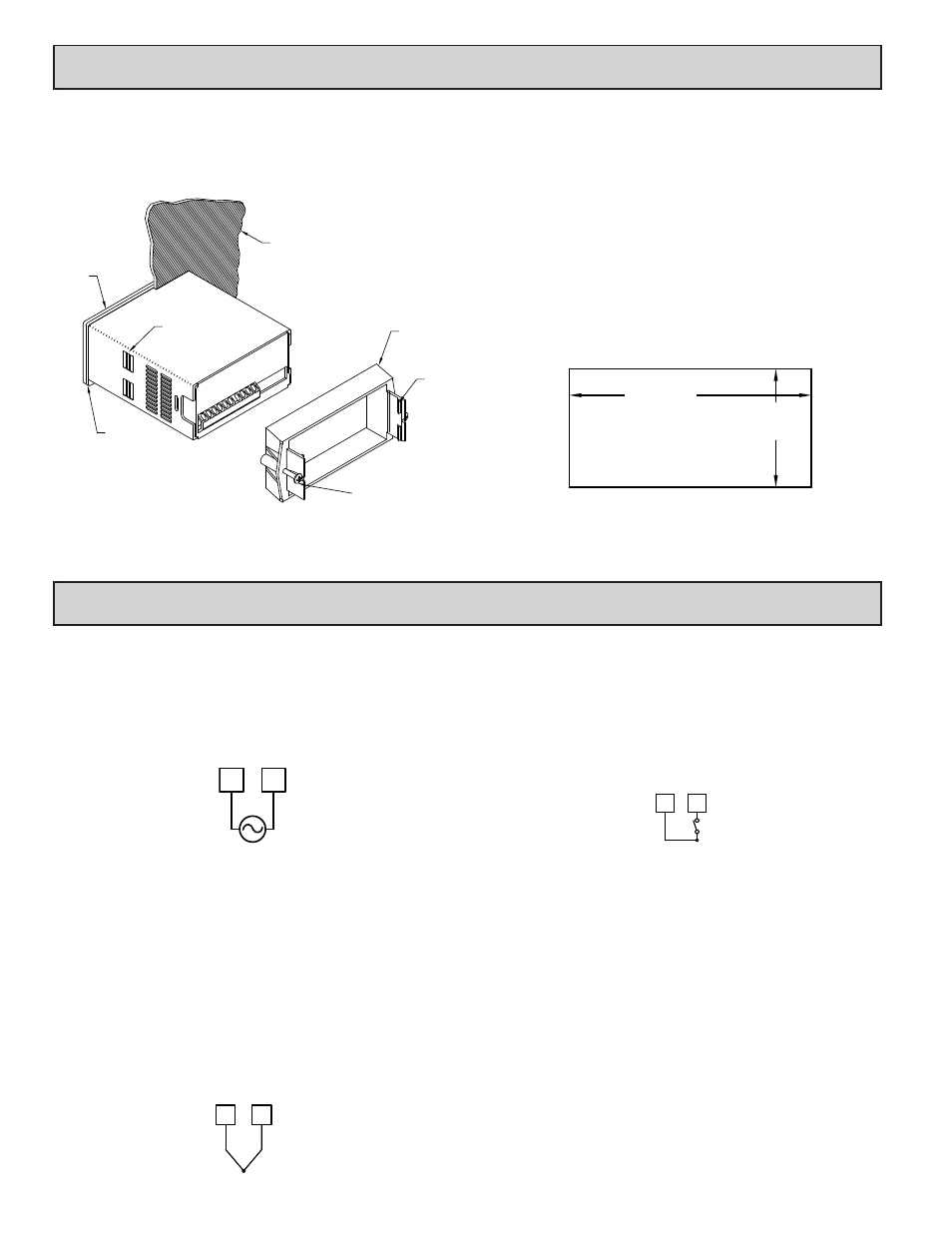

The PAX meets NEMA 4X/IP65 requirements when properly installed. The

unit is intended to be mounted into an enclosed panel. Prepare the panel cutout

to the dimensions shown. Remove the panel latch from the unit. Slide the panel

gasket over the rear of the unit to the back of the bezel. The unit should be

installed fully assembled. Insert the unit into the panel cutout.

While holding the unit in place, push the panel latch over the rear of the unit

so that the tabs of the panel latch engage in the slots on the case. The panel latch

should be engaged in the farthest forward slot possible. To achieve a proper seal,

tighten the latch screws evenly until the unit is snug in the panel (Torque to

approximately 7 in-lbs [79N-cm]). Do not over-tighten the screws.

Installation Environment

The unit should be installed in a location that does not exceed the maximum

operating temperature and provides good air circulation. Placing the unit near

devices that generate excessive heat should be avoided.

The bezel should be cleaned only with a soft cloth and neutral soap product.

Do NOT use solvents. Continuous exposure to direct sunlight may accelerate the

aging process of the bezel.

Do not use tools of any kind (screwdrivers, pens, pencils, etc.) to operate the

keypad of the unit.

-.00

(92 )

-.0

+.8

3.62

+.03

(45 )

1.77

-.0

+.5

-.00

+.02

PANEL CUT-OUT

LATCHING

TABS

PANEL

LATCH

PANEL

MOUNTING

SCREWS

LATCHING

SLOTS

PANEL

GASKET

BEZEL

PANEL

POWER WIRING

Primary AC power is connected to Terminals 1 and 2. To reduce the chance of

noise spikes entering the AC line and affecting the indicator, the AC power should

be relatively “clean” and within the specified limits. Drawing power from heavily

loaded circuits or circuits which also power loads that cycle on and off,

(contactors, relays, motors, machinery, etc.) should be avoided.

SIGNAL WIRING (TC SENSOR)

Remove power and connect the negative thermocouple lead (always red) to

TC- (Terminal 6) and the positive lead to TC+ (Terminal 5). Be certain that

connections are clean and tight. If the thermocouple probe is to be mounted

away from the meter, thermocouple extension grade wire must be used (copper

wire will not work). Use the correct type and observe the correct polarity.

Always refer to the sensor manufacturer’s instructions for probe wiring

connections, if available. For multi-probe temperature averaging applications,

two or more thermocouple probes may be connected at the meter. (Always use

the same type.) In order to minimize the chances of coupling noise into the

wires and subsequently causing bouncy and erroneous readings, proper

guidelines for thermocouple wire routing must be followed.

PROGRAM DISABLE INPUT WIRING

PGM.DIS. (Terminal 3) is a digital input that is active when connected to

Comm (Terminal 4). Any form of mechanical switch or current sinking logic with

less than 0.7 V saturation may be used. The use of shielded cable is recommended.

Follow the EMC Installation Guidelines for shield connection.

WIRING OVERVIEW

Electrical connections are made via screw-clamp terminals located on the

back of the meter. All conductors should conform to the meter’s voltage and

current ratings. All cabling should conform to appropriate standards of good

installation, local codes and regulations. It is recommended that the power

supplied to the meter be protected by a fuse or circuit breaker.

When wiring the meter, compare the numbers embossed on the back of the

meter case against those shown in wiring drawings for proper wire position. Strip

the wire, leaving approximately 0.3" (7.5 mm) bare lead exposed (stranded wires

should be tinned with solder). Insert the lead under the correct screw-clamp

terminal and tighten until the wire is secure. (Pull wire to verify tightness.)

1

2

AC

AC

AC Power

Terminal 1: VAC

Terminal 2: VAC

5

6

+

-

TC+

TC-

COMM

PGM.DIS.

3

4

Thermocouple