Pplications – Red Lion PAXLPV User Manual

Page 8

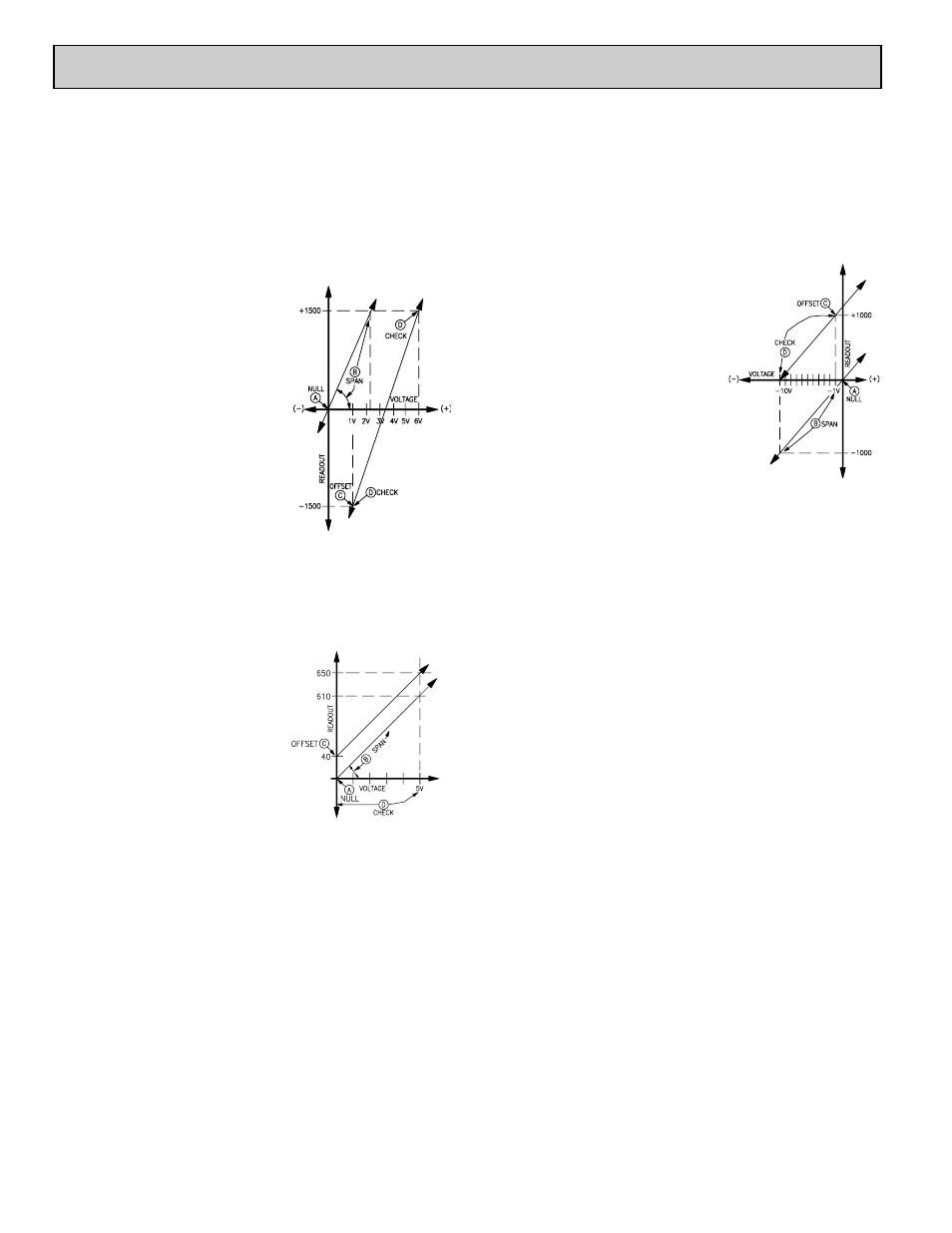

Example 1 (± Display):

A differential pressure transducer has a range of ±15 PSI with a 1-6 V

output (-15 @ 1 V, +15 @ 6 V)

READOUT SPAN (Rs) = +1500 - (-1500) = 3000

SWING VOLTAGE (Vs) = 6 V (max) - 1 V (min) = 5 V

SPAN PER VOLT (Rs/Vs) = 3000 / 5 V = 600

Note: Since the display readout is limited to 1999 numerical indication, the

full READOUT SPAN of 3000 cannot be obtained during zero based span

adjustment. However, dividing both the READOUT SPAN and SWING

VOLTAGE by two, i.e. 1500 readout @ 2.5 V, allows the span adjustment

to be made for the proper transfer curve slope.

ADJUSTMENTS

Null the unit to zero readout @ 0 V per

Steps 1 to 4 of the calibration steps.

Set transfer curve slope with span

adjustments per Steps 5 and 6 to get a

readout of +1500 @ 2.5 V (SPAN PER

VOLT = 600).

Apply (-) offset per Step 7 to get a

reading of -1500 @ 1 V.

Check min. and max. extremes and tweak

if required to get desired readout @ 1 V

and 6 V per step 8. Set D.P. switch S2

and replace unit in case.

Example 2 (Positive Offset):

PAXLPV is to be calibrated to match a flow transducer whose output is 0

V @ 40 GPM and 5 V @ 650 GPM.

READOUT SPAN (Rs) = 650 - 40 = 610

SWING VOLTAGE (Vs) = 5 V (max) - 0 V (min) = 5 V

SPAN PER VOLT (Rs/Vs) = 610 / 5 V = 122

ADJUSTMENTS

Null the unit per Steps 1 to 4 of the

calibration steps.

Set the coarse and fine span adjustments

to get a readout of 610 @ 5 V (SPAN PER

VOLT = 122) per Steps 5 and 6.

Set offset to readout 40 @ 0 V per Step 7.

Check the readout @ max. (5 V) and min.

(0 V) and fine tune (tweak) as required

per Step 8.

Example 3 (Negative Slope):

A liquid level sensor puts out 1 V when a storage tank is full and 11 V

when the tank is empty. The PAXLPV is to read out 100.0 when the tank is

full and zero when the tank is empty.

READOUT SPAN (Rs) = 1000 - 0 = 1000

SWING VOLTAGE (Vs) = 1 V (max) - 11 V (min) = -10 V

SPAN PER VOLT (Rs/Vs) = 1000 / -10 V = -100

In this case, the signal voltage is reversed [Term. 3 (+) with respect to Term.

4 (-)] causing the readout to go “down” (increasingly negative) as the

negative voltage increases (hence, the negative (-) SPAN PER VOLT).

ADJUSTMENTS

Null the unit per Steps 1 to 4 of the

calibration steps.

Set the slope of the transfer curve with the

span adjustments to get a readout of -1000

@ -10V

(SPAN PER VOLT

=

-100) per Steps 5 and 6.

Move the transfer curve up by applying (+)

offset per Step 7 until readout is +1000 @

-1 V.

Check extreme readings per Step 8 0

readout @ -11 V and +1000 @ -1 V. Set

D.P. switch S1 ON and replace unit in case.

6.0 A

PPLICATIONS

Red Lion Controls

20 Willow Springs Circle

York PA 17406

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

Red Lion Controls AP

Unit 101, XinAn Plaza

Building 13, No.99 Tianzhou Road

ShangHai, P.R. China 200223

Tel +86 21 6113-3688

Fax +86 21 6113-3683

Red Lion Controls BV

Printerweg 10

NL - 3821 AD Amersfoort

Tel +31 (0) 334 723 225

Fax +31 (0) 334 893 793