Alibrating, Eter, Calibration procedure – Red Lion PAXLCL User Manual

Page 7: Calibration steps, Troubleshooting

7

5.0 C

ALIBRATING

THE

M

ETER

Direct calibration in the signal loop is usually not practical due to the

difficulty in varying the measured parameter and the confusing interaction that

occurs between span and offset adjustments. However, the PAXLCL can be

quickly and easily bench calibrated using a commercially available current

calibrator or the calibration set-up shown below.

CALIBRATION PROCEDURE

The procedure outlined below minimizes span/offset interaction and

simplifies calibration. In Steps 1 to 4 the unit is “nulled” to zero readout with

zero input signal current. In Steps 5 and 6, the span adjustments are made to

establish the required slope of the transfer curve. Then in Step 7, the transfer

curve is shifted up or down as required by setting the offset adjustments. In Step

8, the final “tweaking” adjustments are made at minimum and maximum signal

current. Setting the decimal points in Step 9 completes the calibration.

Before calibrating, the READOUT SPAN (Rs) and SWING CURRENT (Is)

must be determined.

WHERE:

Rs = (Max. Numerical Display) - (Min. Numerical Display) (Disregard Decimal Points)

Is = (Current @ Max. Display) - (Current @ Min. Display)

Example:

Readout is to be 0.00 @ 4 mA and 10.00 @ 20 mA.

READOUT SPAN (Rs) = 1000 - 0 = 1000

SWING CURRENT (Is) = 20 mA - 4 mA = 16

CALIBRATION STEPS

1. Power down the meter and remove it from its case. Turn off all offset and

span adjustment switches (S2-S10 down). S1 has no effect when zeroing

and can be in either position.

2. Turn the span control pot fully counter-clockwise (20 turns max.).

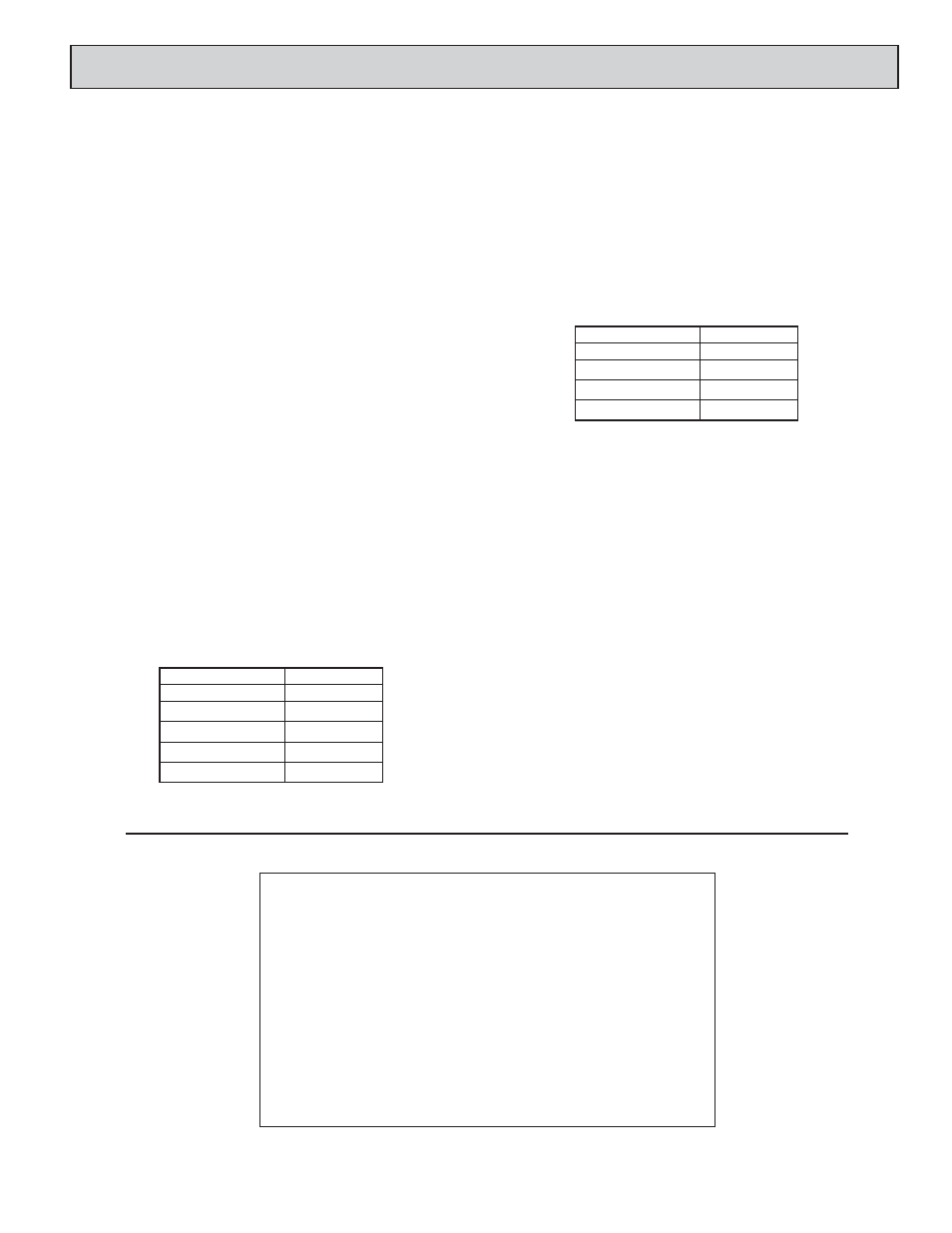

3. Turn on a combination of span adjust switches (6-10) to obtain a total value

closest to (but not greater than) the READOUT SPAN (Rs) desired (1000

in this example). The following chart gives an approximate span

adjustment value for each switch:

4. Place unit in its case and apply power. Apply zero current. Adjust the

indicator to read zero using the offset adjustment pot.

5. Apply the SWING CURRENT (Is) (16 mA in the example) to the input.

Set the exact READOUT SPAN value (1000) with span adj.pot.

6. Apply zero current to see if the zero value has shifted. If it has, re-zero with

the offset pot, then repeat Step 5.

7. After the span has been adjusted, set the signal current to the minimum

level (4 mA in the example). Record the meter reading (in this example the

reading will be 250). Subtract the desired reading at minimum current

value (0 in the example) from the recorded reading (0-250 = - 250). Power

down the meter and remove it from its case. Set the offset add/subtract

switch S1 (subtract = on), and the offset switches (S2-S5) to obtain a total

value closest to (but no more than) the difference between the desired

reading at minimum current value and the observed reading The following

chart gives an approximate offset adjustment value for each switch:

Place the meter in its case and apply power. Using the offset adjust pot,

adjust the readout to equal the desired reading at the minimum current

value (0 in the example).

8. Adjust the input signal current to its maximum value to see if the proper

readout is obtained (1000 @ 20 mA in the example). If the readout is

slightly off, adjust the span pot to obtain the true reading. Then, recheck

the reading at the minimum input current (4 mA) and readjust the offset

pot if necessary. Repeat the maximum and minimum readout adjustments

until the unit displays the proper readout at both extremes.

9. Set decimal points as desired using the three decimal point switches. The

unit can now be installed.

TROUBLESHOOTING

For further assistance, contact technical support at the appropriate company

numbers listed.

SWITCH NUMBER

SPAN VALUE

6

2100

7

1050

8

525

9

260

10

130

175

5

350

4

700

3

1400

2

OFFSET VALUE

SWITCH NUMBER

LIMITED WARRANTY

The Company warrants the products it manufactures against defects in materials and workmanship

for a period limited to two years from the date of shipment, provided the products have been stored,

handled, installed, and used under proper conditions. The Company’s liability under this limited

warranty shall extend only to the repair or replacement of a defective product, at The Company’s

option. The Company disclaims all liability for any affirmation, promise or representation with

respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC

against damages, claims, and expenses arising out of subsequent sales of RLC products or products

containing components manufactured by RLC and based upon personal injuries, deaths, property

damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be

to any extent liable, including without limitation penalties imposed by the Consumer Product Safety

Act (P.L. 92-573) and liability imposed upon any person pursuant to the Magnuson-Moss Warranty

Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except

those expressly contained herein. The Customer acknowledges the disclaimers and limitations

contained herein and relies on no other warranties or affirmations.