Typical dual counter application, Typical counter/rate application, Ordering information – Red Lion GEMINI 42 User Manual

Page 4

4

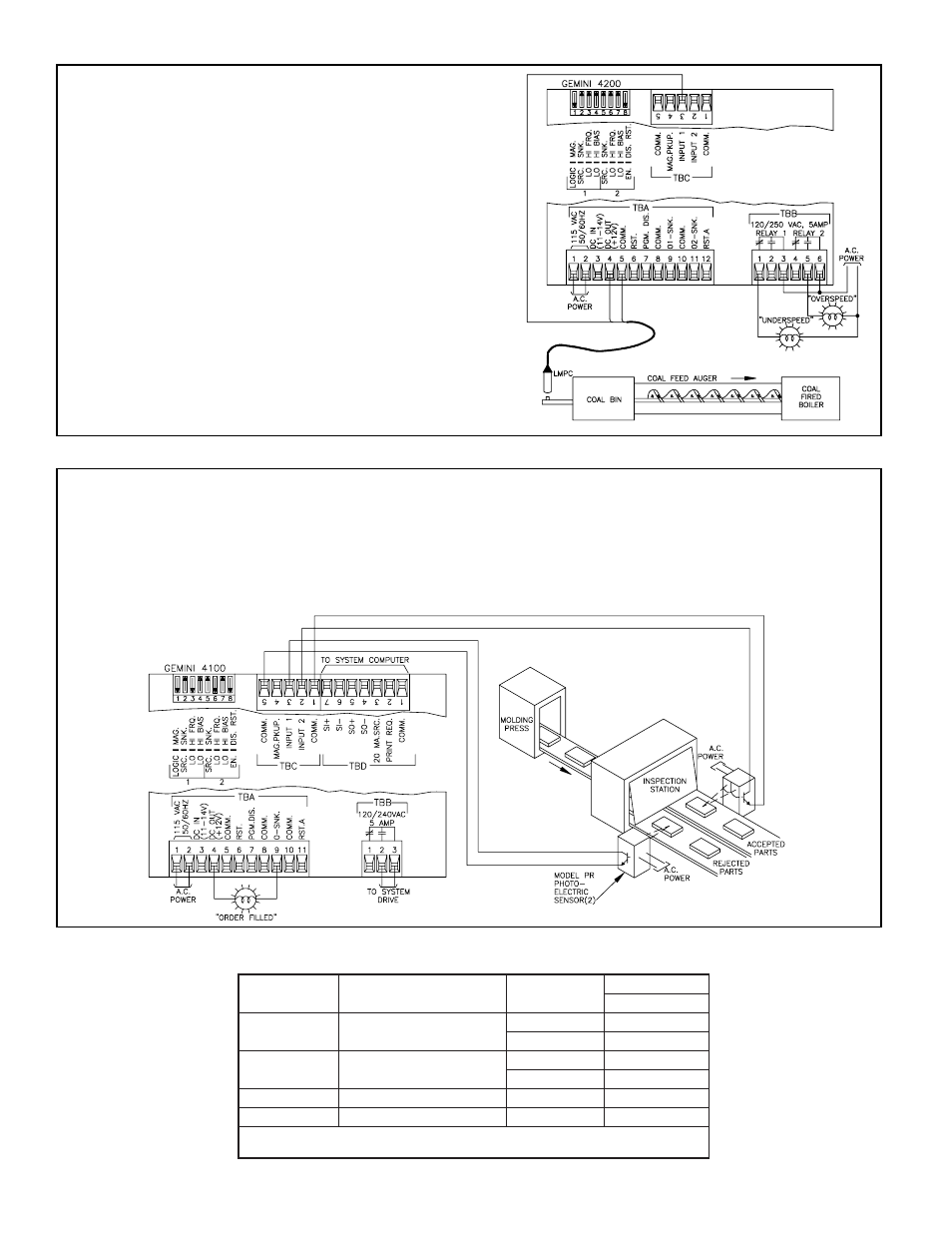

TYPICAL DUAL COUNTER APPLICATION

A manufacturer of molded plastic parts wants to track the percentage of usable

parts versus parts produced to determine if a defect has developed in the mold or

some other malfunction is occurring which requires corrective action.

From the molding press, parts pass through an inspection station and exit on

one of two conveyors depending on whether the part is accepted or rejected. A

Gemini 4100 programmed as a dual counter is used in the separate inputs

mode. Count Channel B tabulates the number of acceptable parts via a photo

sensor mounted on the conveyor. Likewise, count Channel A tabulates the

number of rejected parts from a second photo sensor. A system computer

constantly monitors the two count values through the Gemini Serial

Communications Loop and performs the percentage calculation required.

The single preset output of the Gemini 4100 is assigned to count Channel B

and is set for the number of acceptable pieces required to fill the order. The preset

value could be entered by the operator through the front panel pushbuttons or

could be entered into the system computer and down loaded to the Gemini.

TYPICAL COUNTER/RATE APPLICATION

COAL FEED RATE & USAGE INDICATION

An industrial plant has an in-house coal fired boiler which provides heating

and powers an electric generator used for secondary power. An auger feeds the

coal into the boiler furnace. The actual pressure of the boiler is controlled by

the feed rate of the auger. An indication is required when the feed rate falls

below or exceeds the desired RPM levels. The plant manager also wants an

indication of the amount of coal that is used. The normal desired auger

revolution rate is between 30 and 40 RPM. A shaft rotation speed of 30 RPM

is equal to a feed rate of 1.8 tons of coal per hour. Rate and usage indication

is to be in 10ths of tons per hour.

Since the application requires two presets (upper and lower limits) the

Gemini 4200 programmed as a Counter/Rate indicator is used. An LMPC can

be used to sense a bolt head located on the auger shaft. Both outputs of the

Gemini 4200 are assigned to the Rate channel. First the scaling required for

the counter will be calculated. At 30 RPM the pulse rate per minute is the same

since a single bolthead is being sensed once each revolution. Since it takes one

hour at 30 RPM to use 1.8 tons of coal, the number of pulses accumulated in

that hour will be 1800 (30 PPM x 60 min/hr = 1800). The Scale Factor needed

is 0.01 (SF = desired reading/# of pulses = 18/1800= 0.01). Since the same

information rate and desired reading applies to the rate indication, the same

Scale Factor value will be used. It is then only necessary to program the Rate

Conversion Factor for Rate per Hour. Both Presets are programmed for

boundary operation and the Relay outputs are connected to overspeed and

underspeed indicator lights.

PERCENTAGE OF USABLE PARTS VERSUS PARTS PRODUCED

ORDERING INFORMATION

-

PART NUMBERS

-

MODEL NO.

DESCRIPTION

w/20 mA

CURRENT LOOP

No

GEM41060

GEM42

Yes

GEM41160

115/230 VAC

Gemini 4100

No

GEM42060

GEM41

Yes

GEM42160

Gemini 4200

Gemini 4100 Relay Board

N/A

RLYBD001

Gemini 4200 Relay Board

N/A

RLYBD002

For more information on Pricing. Enclosures, & Panel Mount Kits, refer to the RLC Catalog or

contact your local RLC distributor.