Programming, Typical counter applications – Red Lion GEMINI 2 User Manual

Page 3

3

12. ENVIRONMENTAL CONDITIONS:

Operating Temperature: 0 to 50°C

Storage Temperature: -40 to 80°C

Operating and Storage Humidity: 85% max. relative humidity (non-

condensing) from 0 to 50°C.

Altitude: Up to 2000 meters

13. CONSTRUCTION:

Metal die-cast bezel, plastic case. This unit is rated for NEMA 4/IP65 indoor

use. Installation Category II, Pollution Degree 2

14. WEIGHT: 2.1 lbs. (0.9 kg)

PROGRAMMING

The Gemini 1000/2000 input circuit set-up is programmed using DIP

switches on the rear of the unit. All other functions are programmed through the

front panel pushbuttons.

To program or interrogate a function, the user first enters a two-digit function

code. The unit will then display that function code along with a single-digit

representing the present mode of operation. Programming changes are made by

changing the single-digit mode identifier.

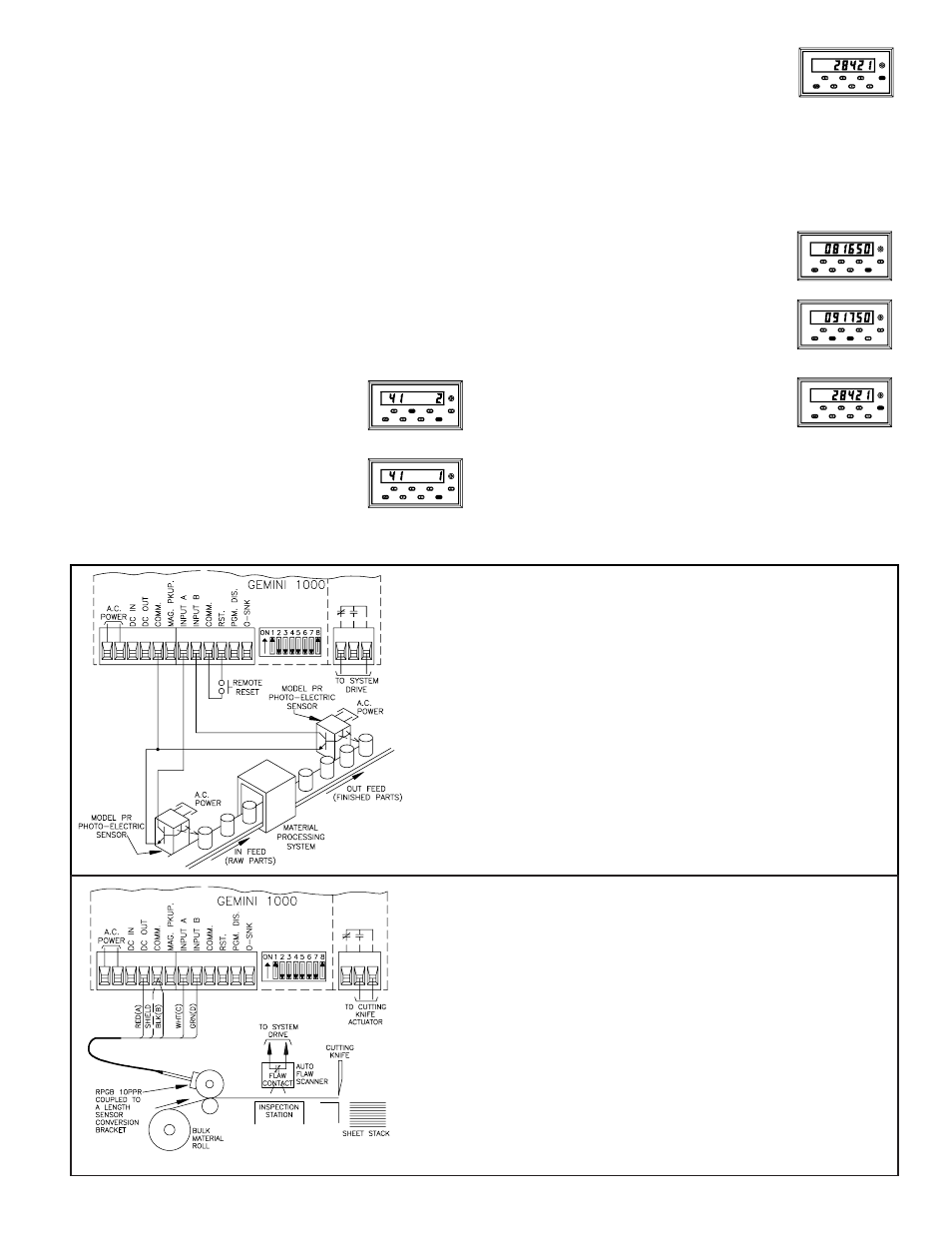

EXAMPLE: The function code representing the “Unit Personality” is 41. The

mode identifiers for this function are:

Counter (1) and Rate Indicator (2).

To interrogate the Unit Personality, Press “41”:

Unit displays function code along with mode identifier

(Rate Indicator).

To change the Unit Personality to Counter mode,

Press “1”:

Unit displays the new mode identifier (Counter).

Press “E”:

Unit enters new mode and returns display to the present

count value.

The most commonly used functions, Preset(s) and Scale Factor, are initialized

through single front panel pushbuttons rather than a two-digit function code.

Pressing the “1” or “3” pushbuttons will immediately display the current Preset

or Scale Factor value for the selected display. To change any digit, the user

presses the pushbutton directly below that particular digit, which is then scrolled

until the desired value is obtained. Each digit is changed, if necessary, in the

same manner until the complete Preset or Scale Factor value is registered on the

display. Pressing the “E” pushbutton completes the entry sequence.

To interrogate the Preset value, Press “1”:

Unit displays current Preset value.

To change the Preset value:

Any digit may be changed by pressing the pushbutton

directly below it. Release the pushbutton when the digit

reaches the desired value.

Press “E”:

Unit enters new Preset value and returns display to the

present count.

“IN PROCESS” MONITORING SYSTEM

Some applications require continuous monitoring of items “in-process”. In this example, a

material processing system is equipped with an in-feed photo-electric scanner to count raw parts

going into the system, and an out-feed scanner to count finished parts leaving the machine. The

number of parts between the in-feed and out-feed is displayed by the GEMINI 1000 operating

in the Anti-Coincidence Add/Subtract mode. In this mode, counts applied to INPUT A are

added while counts applied to INPUT B are subtracted.

Before start-up, the system is completely empty of parts and the counter is reset to zero.

When the operation begins, raw parts move through the in-feed scanner field of view with each

part generating an “up” count. After processing, finished parts appearing at the out-feed scanner

generate “down” counts so the counter continuously displays the number of “in-process” parts.

The GEMINI 1000 preset value is set to the maximum system capacity and the output is used

to control power to the system drive. Therefore, if a jam-up occurs within the system and the

maximum capacity is reached, the counter output will shut down the system drive until the

problem can be corrected.

Conversely, the counter could be used in the Reset-to-Preset mode which delivers an output

at zero. If the supply of raw parts is interrupted, the system will eventually empty and the

counter will reach zero. At this point, the counter output will shut down the system drive until

the supply of raw parts is replenished.

TYPICAL COUNTER APPLICATIONS

“CUT-TO-LENGTH” WITH FLAW DETECTION

In this application, sheets of material are to be cut to length as per customer order with any

flaws being corrected by the vendor. Sales are both domestic and foreign and require lengths to

be measured in either yards or meters.

A rotary pulse generator (RPG) with a 10 pulse/revolution (PPR) quadrature output is

coupled to a length sensor conversion bracket with a 4/10 yard wheel. The GEMINI 1000 is set

up in the Quadrature x4 mode which effectively increases the RPG output to 40 PPR. With the

4/10 yard wheel, the information rate becomes 100 pulses/yard and allows the material to be cut

to the nearest 1/100 yard. The counter display is programmed for two decimal places to provide

a readout in 1/100 yard increments.

The Preset value on the GEMINI 1000 is set to the desired length of material and the output

is used to control power to the cutting knife. The counter is programmed to automatically reset

to zero at the preset value which allows the process to run continuously without losing counts.

If a flaw is detected, a contact in the flaw detector is used to shut down power to the system

drive allowing the material to be “backed-up” to the point at which the flaw occurred. As the

material is rewound, the counter will count “down” to maintain a readout of the total length of

material “in-process”.For metric orders, the scale factor on the GEMINI 1000 is set to 0.9144

which provides the conversion from yards to meters (1 yard = 0.9144 meters). Otherwise, all

equipment and settings remain as above.