Typical batch counter applications (cont’d), Ordering information – Red Lion GEMINI 33 User Manual

Page 4

Gemini 3300

4

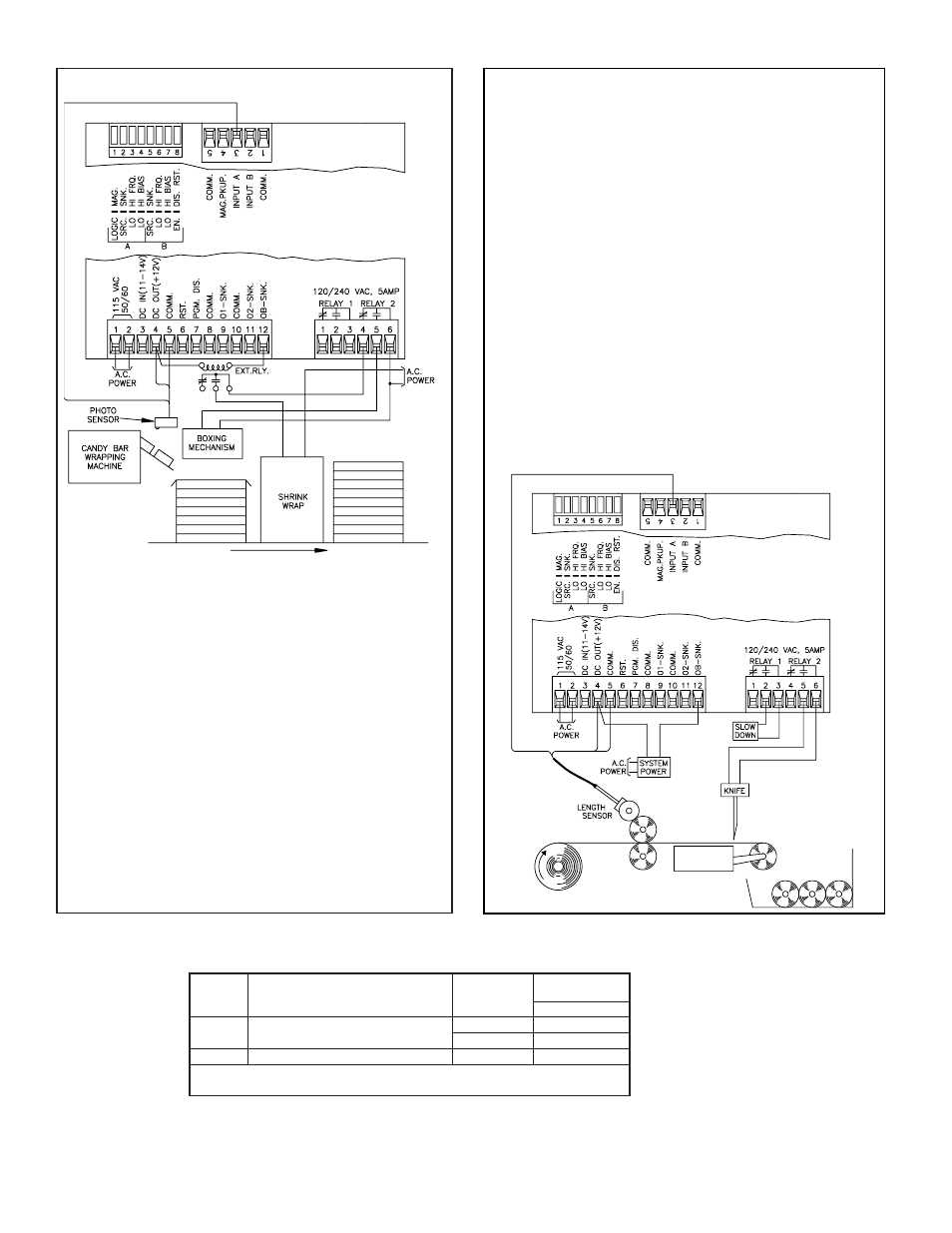

LENGTH PROCESSING UTILIZING SCALE FACTOR

Many times in web type processes it is necessary to scale the input to

reflect the desired engineering units. In this application, a plastic bag

webbing process is being measured with a 10 pulse LSC sensor (length

sensor and one foot circumference wheel). The output of the LSC is the input

to the GEMINI 3300. The requirements are for a readout and control in 10ths

of yards. Thus for every additional yard, the display must increment by 10

counts. A decimal point in the 10ths position will be programmed to provide

the desired display of 1.0 for each yard the process advances. In order to

scale the existing input of 30 pulses per yard to the desired display reading

of 10 (without decimal point), the scale multiplier is programmed as 0.1 and

the scale factor is programmed to 3.3333. After this has been accomplished,

the process control Output 2 is programmed to energize every 40.5 yards to

cut the web in proper lengths. Ten yards before cut, process control Output 1

is to activate to provide a slow-down output. The Batch counter, which

advances 1 count for each cut, can be set to stop the entire process at a

desired production run limit. In this system, the production records require

total yards produced every 24 hours regardless of the particular run in

progress. The totalizing counter of the GEMINI 3300 solves the requirement.

The unit can be programmed so that the Reset Button resets only the Process

and Batch Counters and not the Total Count. This would prevent reset of the

Total Count when setting up for each new production run. The daily tally of

the total can be accomplished by a manual reading. To reset the total count,

a count value of zero can be loaded into the Total Counter (using “Counter

Load Value”), or a reset command can be issued if using the serial

communication capability of the GEMINI 3300.

TYPICAL BATCH COUNTER APPLICATIONS (Cont’d)

CANDY BAR PACKAGING SYSTEM

A typical batching application, shown above, requires two separate

control functions. The first counts the production items in process (candy

bars) and then provides a relay control output to the sealing mechanism

(when 24 candy bars are to be sealed in a distribution box and placed on a

stack). The Batch Counter of the GEMINI 3300 advances each time a

distribution box is sealed. Another packaging mechanism is required to

activate when 10 distribution boxes are stacked, ready to be shrink-wrapped

with clear plastic. Both the Process and Batch Counters are programmed to

reset and Run at the two preset numbers. For the shrink-wrap mechanism

system to operate properly, it must not activate until the Process relay

deactivates after the 24th bar of the 10th box. To achieve this, the power is

fed to the Process Relay 2 common and the normally closed contact is

connected to the common of the Batch Relay. When the process Output 2

fires, it disconnects power to the Batch relay which fires simultaneously

with the Process Relay at the end of a batch. The batch timed output must

be equal to the amount of time required for the shrink-wrap process plus the

time required for the Process Output 2. The Process Output 2 energizes for

0.50 seconds and the required shrink-wrap process time is 4 seconds, so the

batch timed output required is 4.50 seconds. The times are easily

programmed via the front panel. The GEMINI 3300 allows the operator to

maintain a watch on the Process, Batch, or Total Counts by simply pressing

the “+/-” button to sequence the display to the desired count.

ORDERING INFORMATION

PART NUMBERS

DESCRIPTION

MODEL NO.

115/230 VAC

W/20 mA

CURRENT LOOP

RLYBD002

N/A

Gemini 2000/3300 Relay Board

_

GEM33160

Yes

GEM33060

No

Gemini 3300

GEM33

For more information on Pricing, Enclosures, & Panel Mount Kits, refer to the RLC

Catalog or contact your local RLC distributor.