Programming, Typical batch counter applications – Red Lion GEMINI 33 User Manual

Page 3

3

PROGRAMMING

The GEMINI 3300 input circuit set-up is programmed using DIP switches

on the rear of the unit. All other functions are programmed through the front

panel pushbuttons.

To program or interrogate a function, the user first enters a two-digit function

code. The unit will then display that function code along with a single digit

representing the present mode of operation. Programming changes are made by

changing the single-digit mode identifier.

EXAMPLE: The function code representing the “Inputs A and B Response

Modes” is 43. The mode identifiers for this function are:

1) Count (A) with Inhibit (B)

2) Count (A) with Up/Down Control (B)

3) 2-Input Anti-Coincidence Add (A)/Subtract (B)

4) 2-Input Anti-Coincidence Summing

5) Quadrature

6) Quadrature X 4

To interrogate the counting modes, press 43:

Unit displays the function code along with mode

identifier 1 (Count with inhibit).

To change the counting mode to “Count with UP/DN

control”, press 2:

To enter and save the new mode, Press “E”:

Unit enters new mode and returns display to the present

count value.

The GEMINI 3300 can display any of the three count values: The Process

(P) Count, the Batch (B) Count, or the Total (T) Count.

Three indicator LEDs along the left side of the window

indicate which count is currently being displayed.

To display a different count value:

Press the “+/-” pushbutton repeatedly until the

indicator corresponding to the desired count turns on.

The most commonly used functions, Presets and Scale Factor, have

dedicated pushbuttons associated with them. When the Process Count is on the

display, pressing “1” or “2” will display Preset 1 or 2. When the Batch Count

is on the display, pressing “1” will display the Batch Preset. Pressing the “3”

key when viewing any count value, will display the Scale Factor. To change

any digit of that value, the user presses the pushbutton directly below that

particular digit, which is then scrolled until the desired value is obtained. Each

digit is changed, if necessary, in the same manner until the complete Preset or

Scale Factor value is registered on the display. Pressing the “E” pushbutton

completes the entry sequence.

To interrogate the Batch Preset value, Press “+/-” if

necessary, until the Batch Count value is on the display

(B annunciator is lit);

Press “1”:

Unit displays the current Batch Preset value.

To change the Batch Preset value:

Any digit may be changed by pressing the pushbutton

directly below it. Release the pushbutton when the digit

reaches the desired value.

Press “E” to enter new Batch Preset value:

The GEMINI 3300 will then return to displaying the

count value.

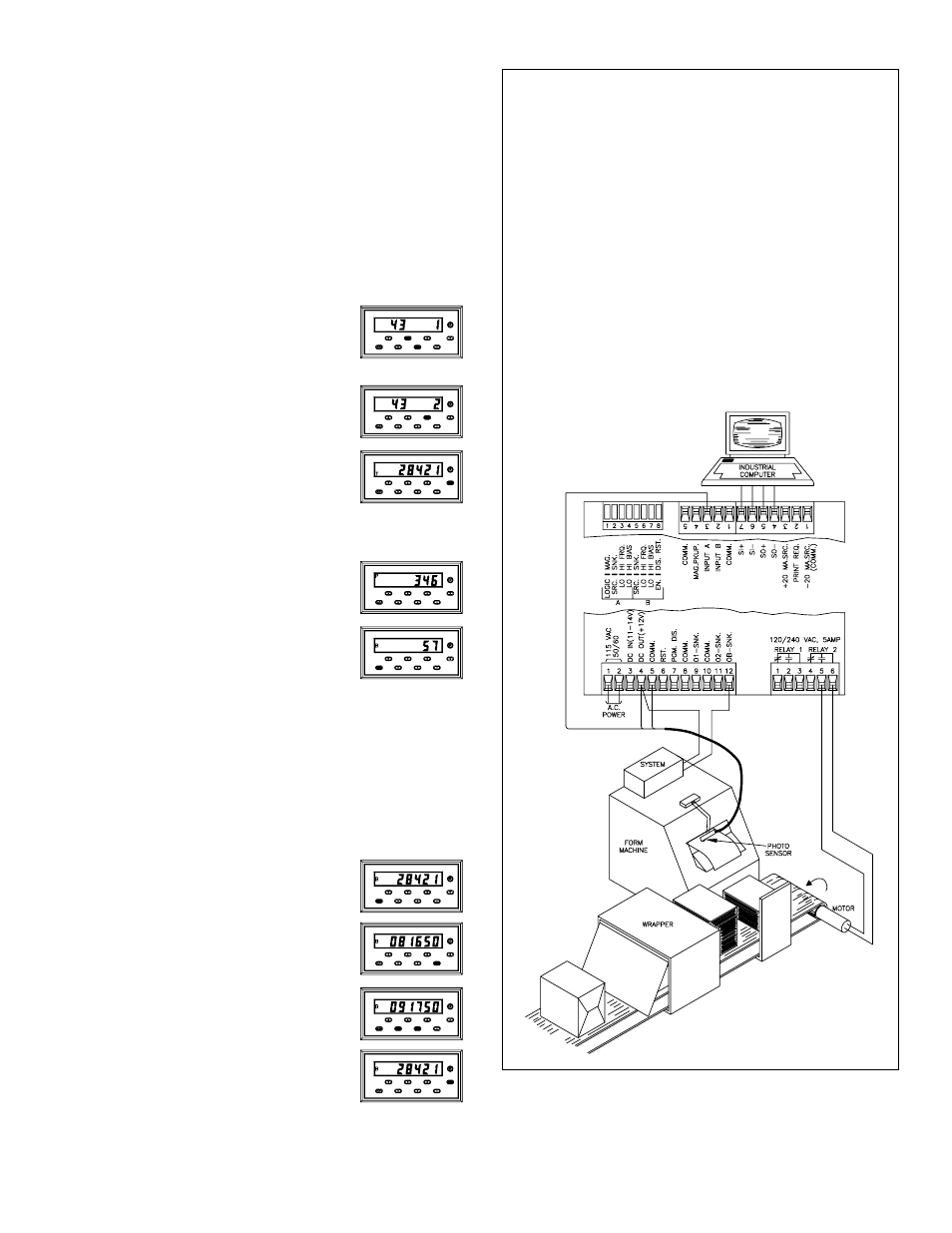

FORMS PACKAGING WITH COMMUNICATIONS

The system depicted below is an excellent example of the

communications capability of the GEMINI 3300. The GEMINI is being

employed to update an existing Process, in order to add indication, control,

and monitoring of the machinery. The machine in question prints and packs

business forms. The requirement exists for a control output when a specific

number of forms are packaged. Another control output is needed when a

specified number of packets have been manufactured. It is necessary to be

able to change the two quantities via the central control system. The

GEMINI’s Process Counter counts input pulses from the form counting

photo sensor. When Preset 2 is reached, Relay 2 and Solid-state Output 2

activate. The Form C relay contacts are used to signal the packaging

mechanism that the desired number of forms have been accumulated. The

GEMINI’s Batch Count output is used in the same manner to stop the entire

process when the desired amount of packages being produced in the line

have been completed. The number of forms in each packet and the number

of packets produced seldom remain the same for two consecutive runs. The

capability to load the desired process and Batch presets remotely by an

external control system is made possible by the optional 20 mA current loop

of the GEMINI. The communications allow for remote monitoring and

control of the GEMINI count and presets. Both of these factors account for

a much improved production capability for this process.

TYPICAL BATCH COUNTER APPLICATIONS