Vibration influence factors – Sandvik Coromant Silent tools - application guide User Manual

Page 75

73

4. Boring

Vibration influence factors

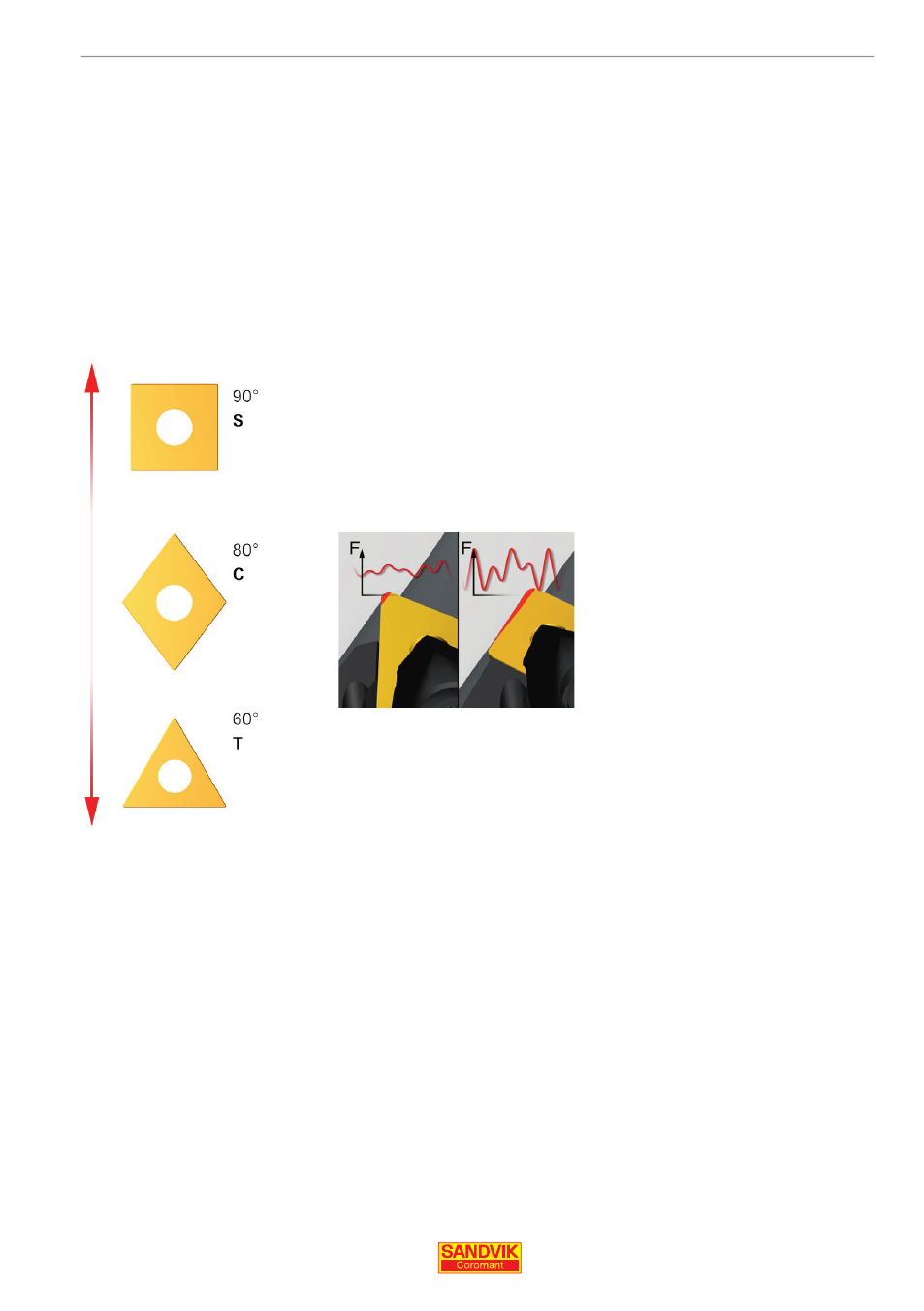

To reduce vibrations, choose a light cutting insert with a positive

cutting geometry and small nose radius. T-style inserts are first

choice for boring operations.

High vibration tendency

– Heavy feeds

– Large depth of cut

– Strong edge security

Less vibration tendency

– Ideal for small depth of cut

– Reduces vibration

Information about other vibration influence factors such as the fol-

lowing can be found in the application guide on page 41-47.

• Insert point angle

• Positive geometries

• Wiper inserts

• Edge rounding

• Cutting data and cutting speed.