Factors that influence vibration – Sandvik Coromant Silent tools - application guide User Manual

Page 43

41

3. Turning

Factors that influence vibration

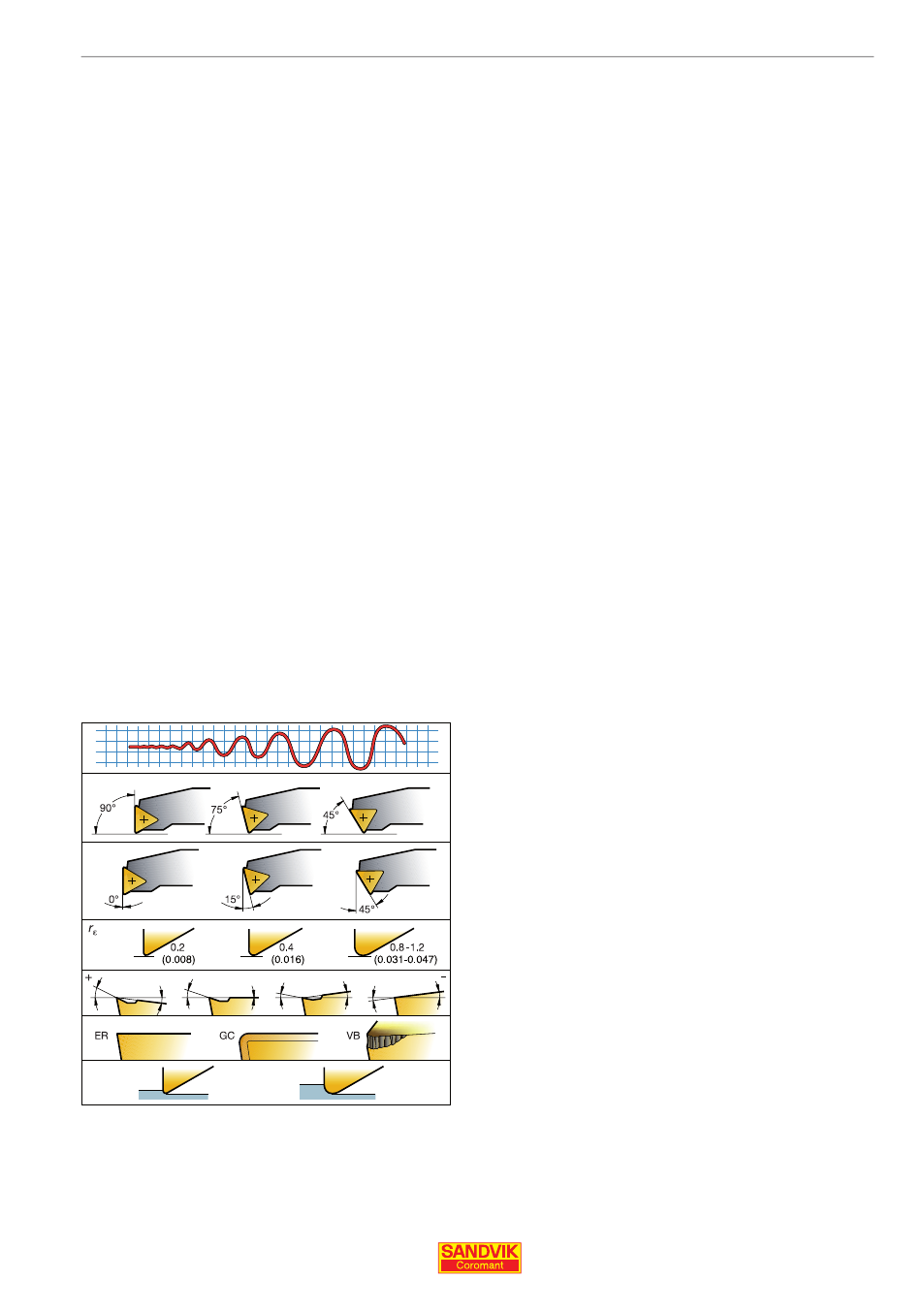

To minimize vibration tendencies:

• Use a large entering angle and positive rake angle

• Use big nose radii and point angle

• Use a positive macro geometry

• Control the wear pattern and ER-treatment on the micro geometry

• Depth of cut should be larger than the nose radius.

Lower radial force gives less radial deflection and fewer problems

with vibration. For best results; use a radial depth of cut that is

larger than the nose radius when using a 90° entering angle

(0° lead angle). If the radial depth of cut is smaller, a 45° entering

angle will give you equal results.

Vibration tendency

Entering/lead angle and rake angle

Nose radius and point angle, mm (inch)

Macro geometry

Micro geometry

Depth of cut related to nose radius