Nose radius in relation to depth of cut – Sandvik Coromant Silent tools - application guide User Manual

Page 71

69

4. Boring

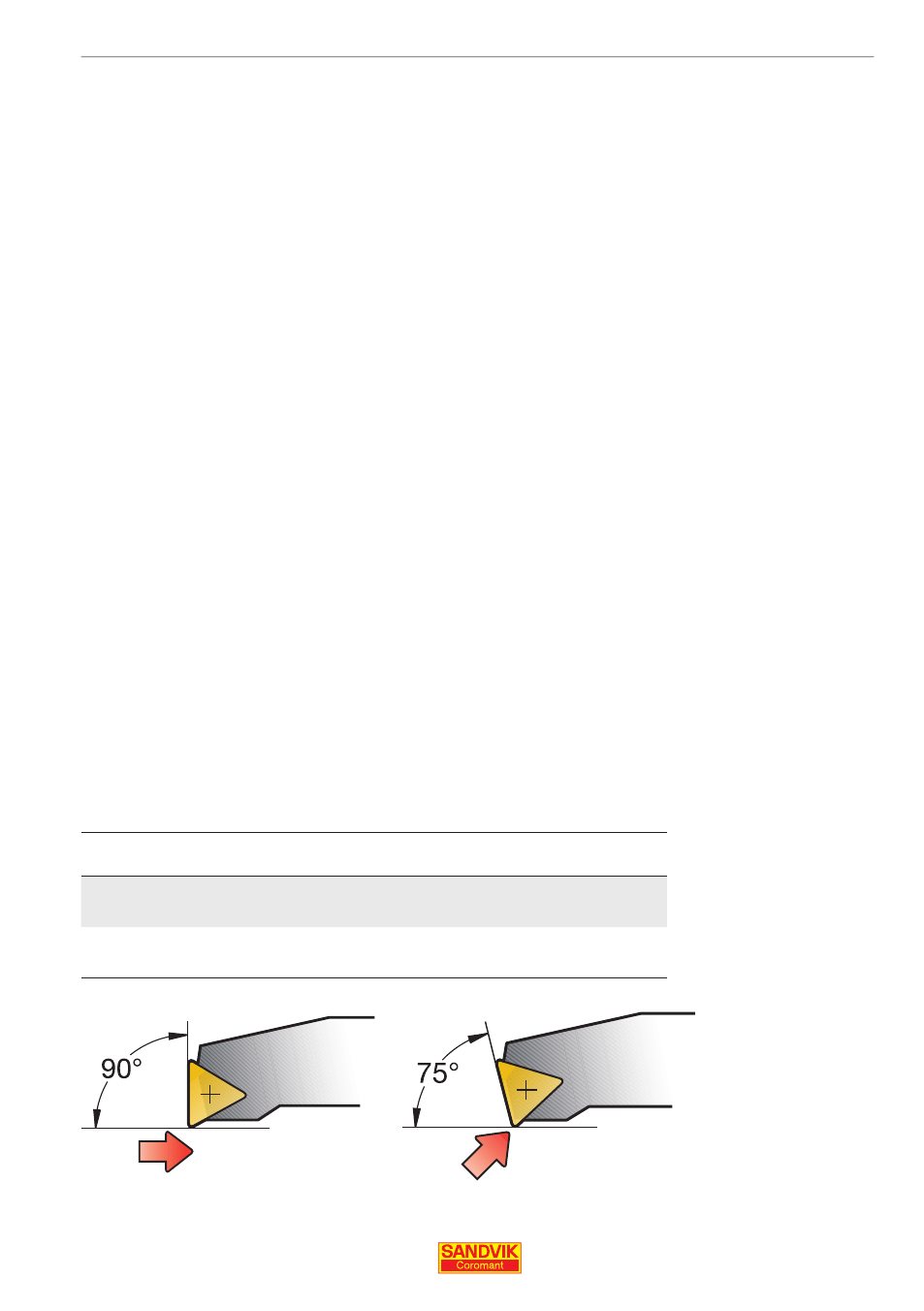

Force direction mainly axial

Force direction both axial and radial

Nose radius in relation to depth of cut

The radial forces that push the insert away from the cutting surface

become more axial as the depth of cut increases. The nose radius

also affects the chip formation. Generally, chip breaking improves

with a smaller radius. As a general rule of thumb, the depth of cut

should be greater than or equal to 2/3 of the nose radius or half

the nose radius in the feed direction.

Feed starting values depending on nose radius

Nose radius size

(mm)

0.4

0.8

1.2

Feed

(mm/r)

0.17

0.22

0.27