Mk f π 2 1 – Sandvik Coromant Silent tools - application guide User Manual

Page 10

8

m

k

f

π

2

1

=

1. Introduction

In summary:

1. Reduce cutting forces by choosing the right cutting tool and

insert

2. Minimize deflection by increasing the static stiffness through

largest possible shank diameter and minumum length

3. Reduced weight on cutting units will minimize the kinetic energy

in a potential vibration

4. When extending modular tools, build large diameters

5. For engineered products, consider optimized shapes and

material reinforcements

Vibration basics

Mechanical structures tend to vibrate with one or more resonance

frequencies determined by geometry and material. Each resonance

frequency corresponds to a ”vibration mode”. The dampening deter-

mines how fast the vibration settles after being triggered. With increased

deflection, the energy in the oscillation increases.

The force variations in machining will trigger the self-induced vibration

at the natural frequencies of the machine tool. Once the vibration is

triggered, it will feed on the forced vibration and grow larger and larger,

unless you can reduce the force variations.

Variations in machining forces can depend on a number of things, and if

nothing is done to reduce the cutting forces, the vibration will increase.

•

Chip segmenting process

•

Interrupted cut

•

Inclusions in the material

•

Ovality in the workpiece

•

Formation of built-up edge

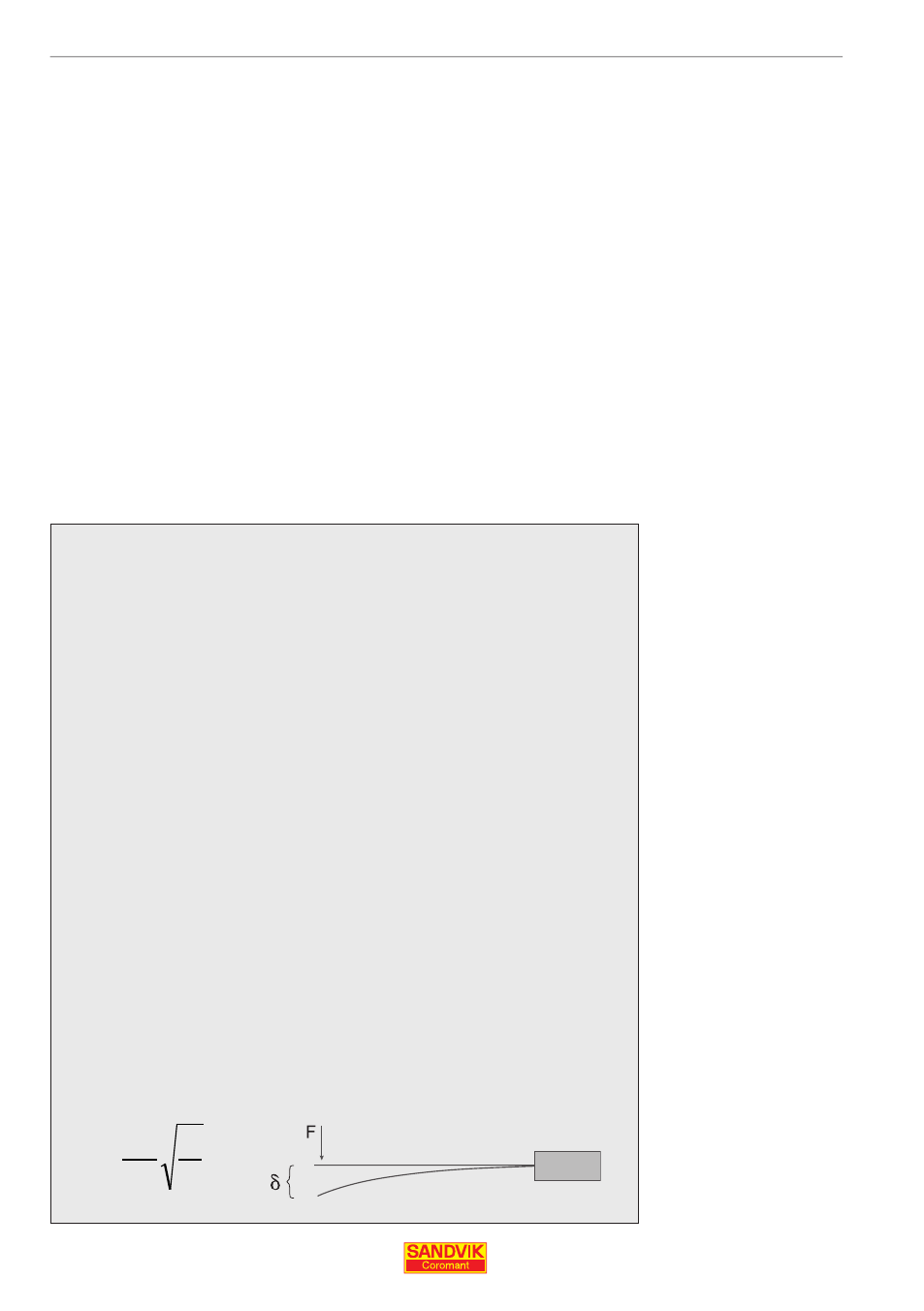

k = spring constant

m = object mass

f = vibration frequenzy

δ = tool deflection

F = force on the tool