Achieve maximum q, Chip evacuation, Entry and exit – Sandvik Coromant Silent tools - application guide User Manual

Page 34

32

2. Milling

Achieve maximum Q

Choose a

e

between 60%–80% as a starting value if possible.

Reduce the number of inserts to maximize Q. This is particularly

important when using full slot engagement.

Chip evacuation

Use compressed air to prevent re-cutting of the chips. This is

especially important in deep-cavity milling. Notice that a coarse

pitch cutter will have more space to evacuate the chips.

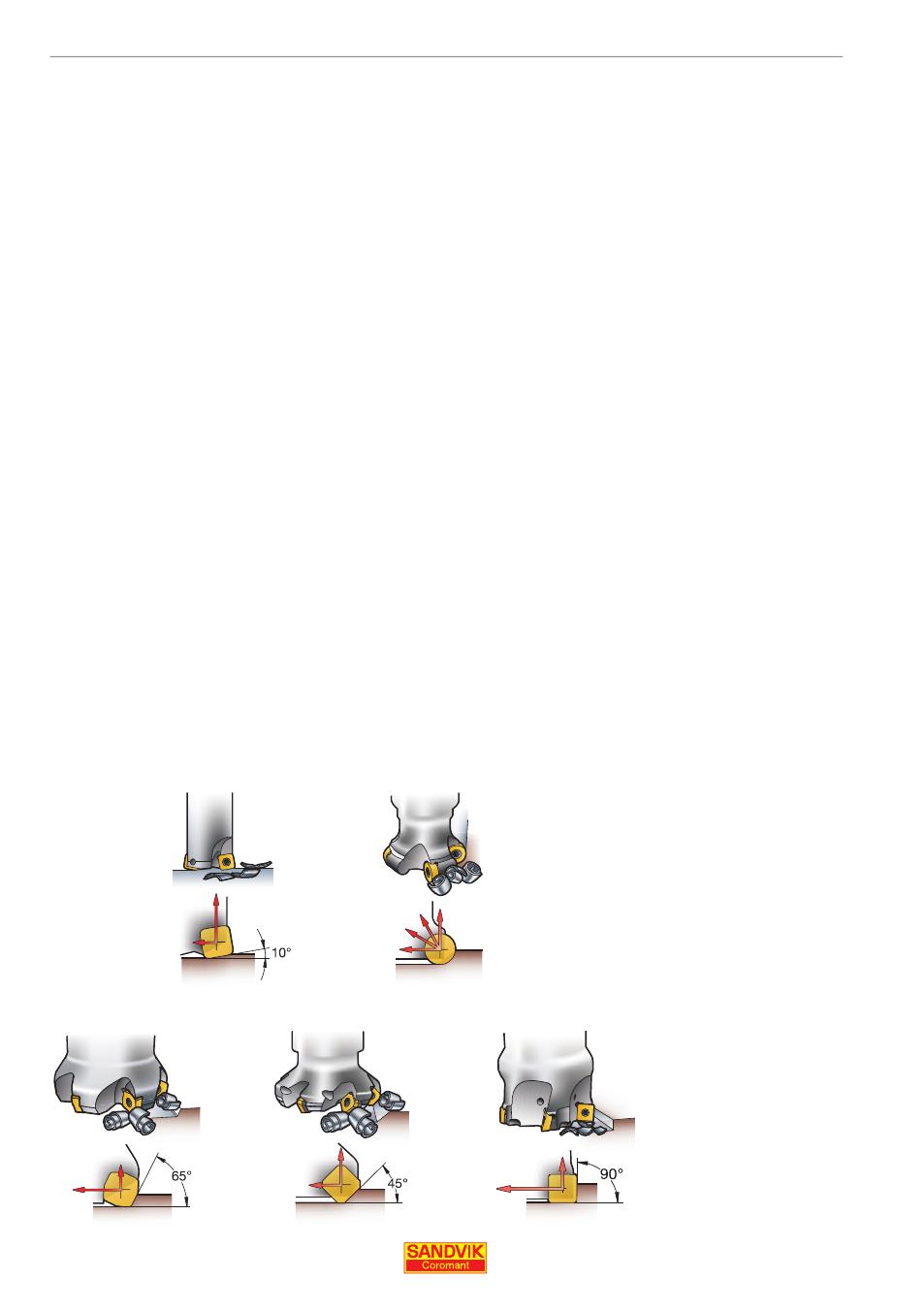

Entry and exit

Avoid situations where the centre line or the cutter is in line with

the workpiece edge. In situations like that, the insert is leaving cut

when the chip thickness is at its maximum, which gives very high

shock-loads at entry and exit.