Sandvik Coromant Silent tools - application guide User Manual

Page 31

29

2. Milling

The valve housing has a total length of 850 mm (33.46 inch) and a

production volume of 300 units per year. In January 2012 the valve

housing underwent a small process change. The length of the valve

housing demanded processing from both sides and the modifica-

tion involved finishing of the internal diameter of 140 mm (5.51

inch) with a maximum cutting length of 425 mm (16.73 inch).

The process was rationalized from two rough boring cuts, followed

by a flushing operation to remove chips before the final finishing to

Ø140 H7, to one circular interpolation and the final boring finish.

The milling adaptor, C8-391.05CD-27 360 was combined with a

basic holder and an oversized CoroMill 390, acquiring an assembly

length of 480 mm (18.9 inch).

By changing the process the customer saves EUR 22,000 per year.

This equals a payback time of nine weeks, or 64 produced

components. Another great bonus was that tool life increased

from two produced units to ten!

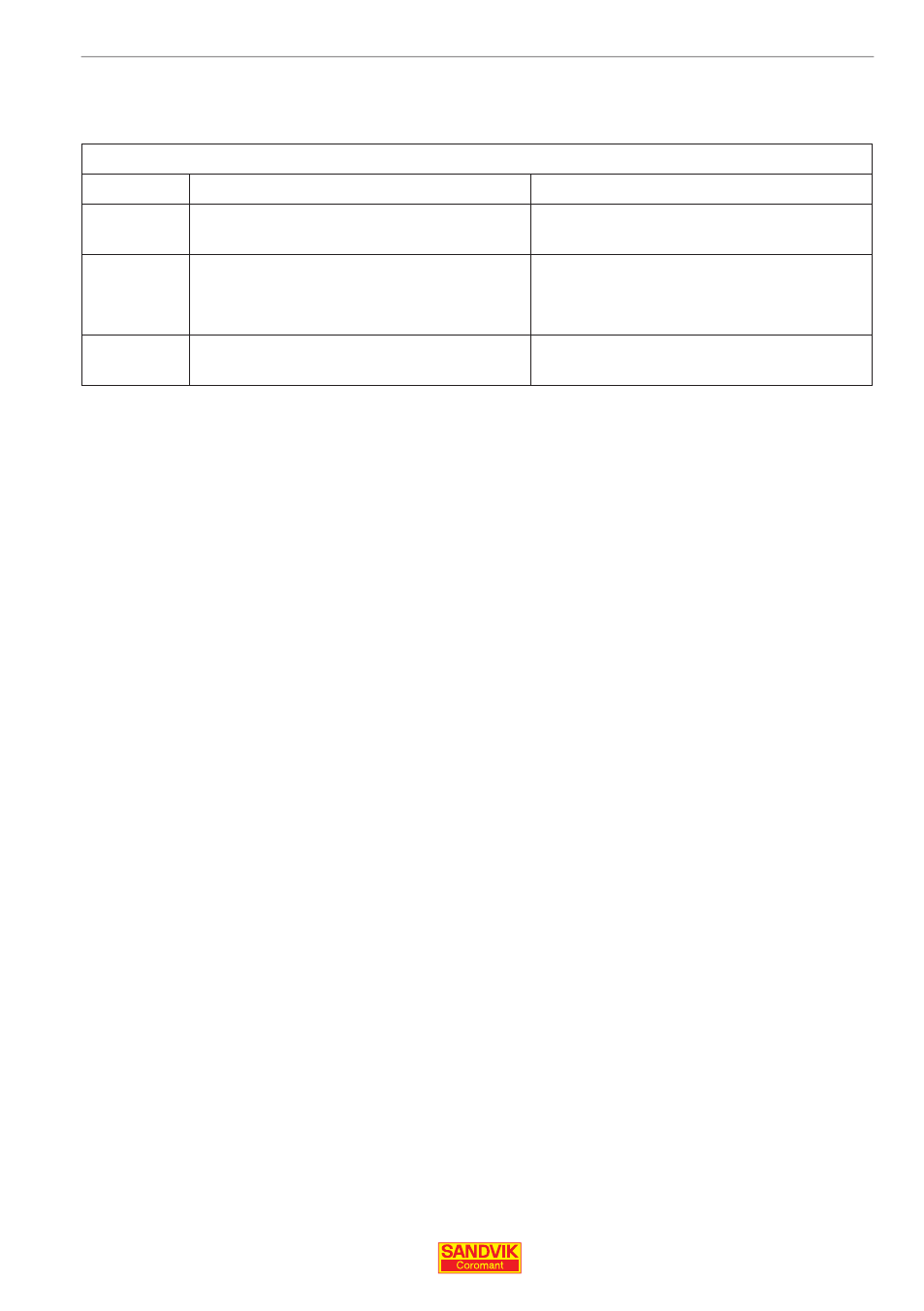

Step machining from one side

Reference

Recommended

Step 1

Rough boring to diameter 135 mm

(5.31 inch)

Circular interpolation to diameter

139.8 mm (5.50 inch)

Step 2

Rough boring to diameter 139.8 mm

(5.50 inch)

Finishing boring to diameter 140 mm

(5.51 inch) H7

Step 3

Flushing

Step 4

Finishing boring to diameter 140 mm

(5.51 inch) H7