Grounding, Wiring – Outback Power Systems GS Load Center Installation Manual User Manual

Page 25

Wiring

900-0123-01-00 Rev B

23

Wiring

Table 2

Terminal Bus Bar (TBB) Wire Size and Torque Requirements

Conductor Size

Torque Requirements

AWG mm2

In-lb Nm

#14 – #10

2.5 – 4

20

2.3

#8

6 – 10

25

2.8

#6 – #3

16 – 25

35

4.0

#2 35

40 4.5

#1 – 1/0

50

50

5.7

Grounding

WARNING: Shock Hazard

The unit must be connected to a grounded, permanent wiring system. If a bond is made

between neutral and ground, make sure only one bond is present in the AC system at any

time. The GSLC comes equipped with a neutral-ground bond. This bond may need to

be disconnected. Some codes require the bond to be made at the main panel only.

WARNING: Shock Hazard

For all installations, the negative (–) battery conductor should be bonded to the

grounding system at only one point. The GSLC comes equipped with a negative-

ground bond. This bond may need to be disconnected. If the OutBack GFDI is present, it

can provide the bond. See page 24.

IMPORTANT:

Most OutBack products are not designed for use in a positive-grounded system. If it is

necessary to build a positive-grounded system with OutBack products, contact OutBack

Technical Support at +1.360.618.4363 before proceeding. Additionally, consult the

online forum at www.outbackpower.com/forum/, where this subject has been

discussed extensively.

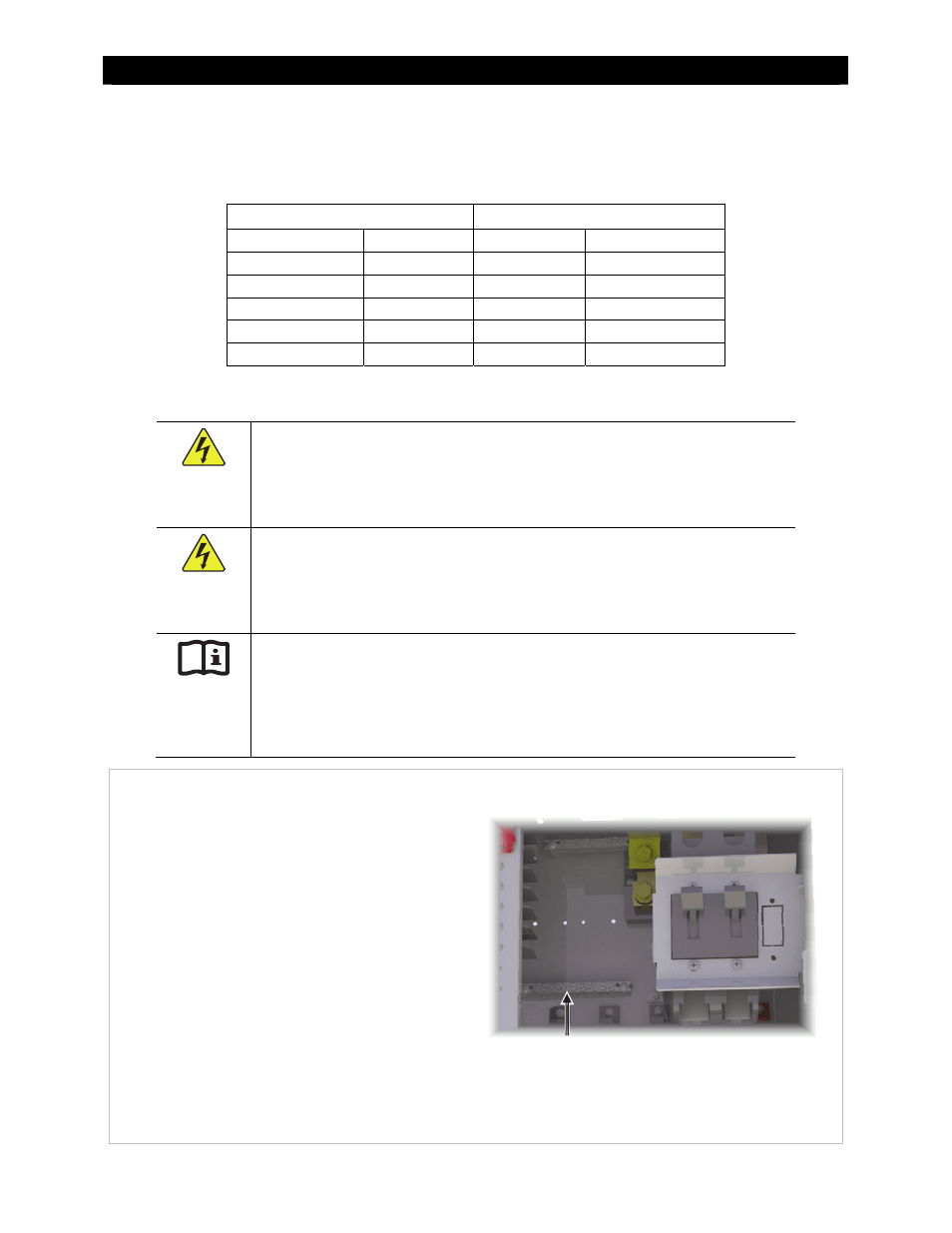

Figure 23

Grounding

The GSLC’s grounding TBB, which is bonded to

the GSLC chassis, is located to the lower left of

the main inverter disconnect. It accepts

conductor sizes from 1/0 to #14 AWG (50 mm

down to 2.5 mm).

This TBB accepts ground connections from the

Radian inverter, FLEXmax charge controllers, the

OutBack GFDI, the Grounding Electrode Conductor

(GEC) or external earth ground, and other

equipment.

See the Radian Series Inverter/Charger Installation

Manual for recommendations on ground

conductor sizing. Once the size is determined,

see Table

2 for required torque values.

Ground TBB