Drive belt removal and replacement, Warning – Alliance Laundry Systems HX User Manual

Page 74

72

9001900

Section 4 Service Procedures

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

To reduce the risk of electrical shock, fire, explosion, serious injury or death:

• Disconnect electrical power to the washer-extractor before servicing it.

• Close the gas shut-off valve to the washer-extractor (when applicable) before servicing it.

• Never start the washer-extractor with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer-extractor is properly grounded.

W461R1

WARNING

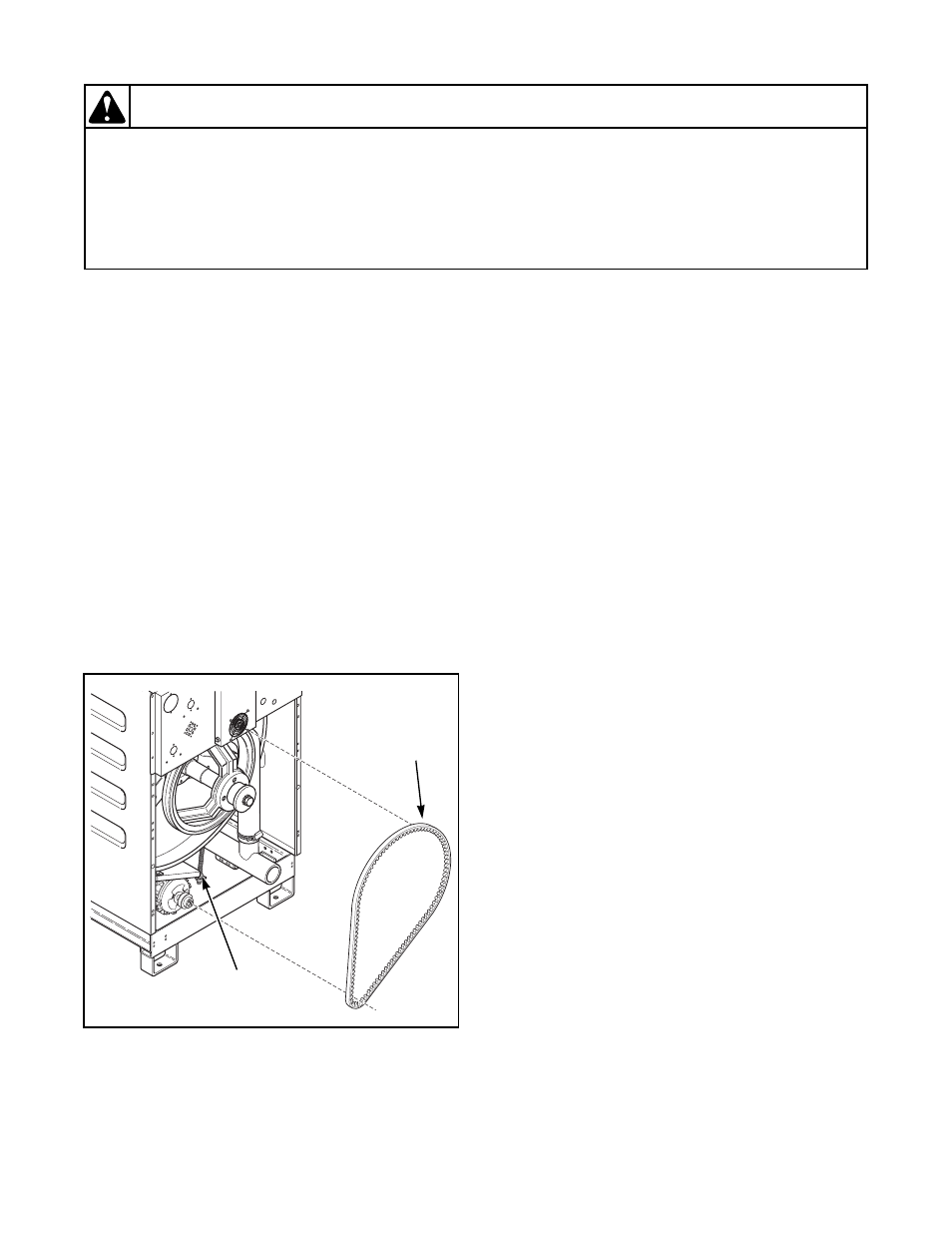

26. DRIVE BELT REMOVAL AND

REPLACEMENT

Refer to Figure 10.

If the drive belt is generating noise or if the AC

drive is generating faults because of excessive

hertz fluctuations, first inspect the belt for wear. If

the belt has uneven wear or frayed edges, replace

it. Refer to the Removal and Replacement

sections, below. If the drive belt isn’t noticeably

worn, check the belt’s tension and deflection.

Refer to the Drive Belt Re-Tensioning section,

below.

REMOVAL

a. Turn off power to the machine.

b. Remove the rear panel. Refer to Paragraph 24.

c. Relieve the belt’s tension by loosening the nuts

on the motor mounting plate bolt.

d. Remove the belt from the motor and basket

pulleys.

REPLACEMENT

a. Install the belt onto the motor and basket

pulleys.

b. Re-tension the belt. Refer to Drive Belt Re-

tensioning, below.

c. Replace the rear panel. Refer to Paragraph 24.

DRIVE BELT RE-TENSIONING

Refer to Figure 11.

a. Turn off power to the machine.

b. Remove the rear panel. Refer to Paragraph 24.

c. Check drive belt tension.

(1) Using a tension gauge, check the drive belt

tension. Belt tension should be between 70

and 90 pounds (± 5 pounds). Set the initial

belt tension toward the high end of the

range.

(2) To adjust the drive belt tension, loosen or

tighten the nuts on the motor mounting

plate bolt. Refer to Figure 10.

d. Check the belt deflection.

(1) Belt deflection measurements should be

taken as close to the center of the belt span

as possible.

(2) For every inch of span length, the drive belt

should deflect 1/64 inch (.4 mm). For

example, a belt with a span length of 50

inches should deflect 50/64 inch (19.84

mm).

(3) An initial (run-in) force of 5.25 pounds

should be used to set the belt tension. An

operating (normal) force of 3.5 pounds

should be used after the washer-extractor

has been operated for a few hours.

e. Replace the rear panel. Refer to Paragraph 24.

Figure 10

CFD14S

Motor Mounting

Plate Bolt

Belt