Lokar Automatic Trans Mount Shifter Ford AOD, 4R70W, and AODE User Manual

Page 5

INS0087 Rev. 06/03/14

Page 5

© 2005 Lokar, Inc.

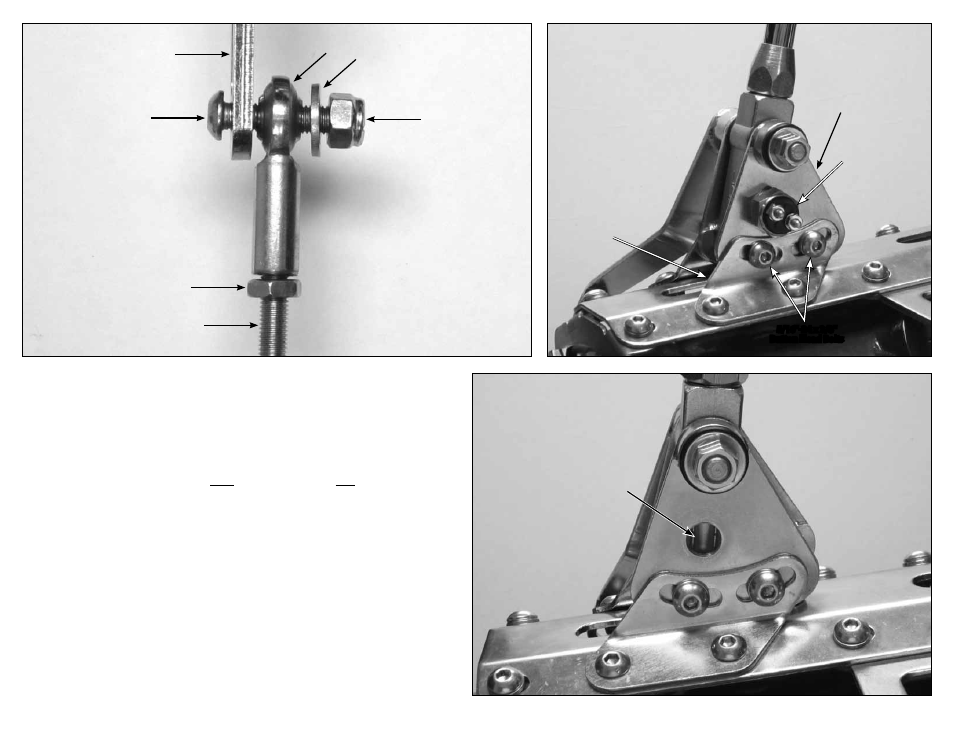

Step 13: The threaded rod will connect the quad lever to the trans arm. Check to make sure that nothing will interfere with

the travel of the threaded rod. If there is any interference, the threaded rod can be bent slightly as needed. On a

4R70W or AODE it may be necessary to adjust the threaded rod to clear the MLPS (manual lever position switch

or neutral safety switch).

Verify that both the shifter and the transmission are in the Park position. Measure center-to-center between the

1/4" holes in the trans arm on the transmission and the quad lever on the shifter. Subtract 1-3/4".

Fig. 8 This is

the length you will cut the threaded rod to. Use a hacksaw or other metal-cutting saw to shorten the threaded rod.

Step 14: Verify that both 1/4"-28 jam nuts are on the threaded rod, and install a rod end onto each end of the threaded

rod. Attach the threaded rod assembly to the

outside of the quad lever and to the inside of the trans arm using

the 1/4"-28 x 1" button head bolts, flat washers, and nylock nuts as shown in

Fig. 9 and Fig. 10. The button head

bolts can be installed from either direction, but make sure the rod end is sandwiched between the flat washer and

the quad lever or trans arm.

Step 15: Check the adjustment of the shifter by placing the shifter all the way forward into the Park position. Make sure

that the release button still moves up and down freely. The release button should be flush with the knob in Park

and Neutral. In the Reverse position, you cannot pull the lever back into Neutral without depressing the release

button.

While the shifter is in the Park position, make sure the transmission is firmly in the "Park" detent, with no

tension on the threaded rod. You can verify this by removing the 1/4"-28 x 1" button head bolt with nylock nut

that attaches the rod end to the quad lever or trans arm at either end of the threaded rod. Make sure the hole in

the rod end exactly aligns with the hole in the quad lever or trans arm. The bolt should pass freely through both

holes at the same time without binding. Do not force the holes to line up.

If the holes are not aligned, screw the rod end in or out just enough to be able to slide the bolt in and out without

putting tension on the threaded rod. Make sure that the quad lever and trans arm do not move during the

adjustment procedure. Use this adjustment routine until the bolt will pass freely in and out of both the rod end

and the quad lever or trans arm. Reinstall the 1/4"-28 nylock nut and the flat washer in its proper position onto

the bolt, and tighten.

Once you have the shifter adjusted correctly, tighten the jam nuts on the threaded rod.

Fig. 10

Fig. 11

Fig. 12

1/4"-28 x 1"

Button Head Bolt

Switch Plate

Neutral Safety

Switch and

Washer

Center Groove

in Shifter Body

Rod End

NOTE: Bolt can be installed from

either side. Make sure the Rod

End is sandwiched between the

Flat Washer and Trans Arm.

Threaded Rod

1/4"-28 Jam Nut

Trans Arm

1/4"-28

Nylock Nut

Flat Washer

Right Side

Banana

Bracket

5/16"-24 x 3/8"

Button Head Bolts