Lokar Ford AOD, AODE, and 4R70W Selector Shaft, Flange, & Arm User Manual

Lokar For the car

Building American Quality… With A Lifetime Warranty!

TOLL FREE 1-877-469-7440 • [email protected] • www.lokar.com

®

Ford AOD, AODE, and 4R70W Selector Shaft, Flange, & Arm

Installation Instructions

Ford AOD, AODE, and 4R70W Selector Shaft, Flange, & Arm

Installation Instructions

INS0030 Rev. 07/26/13 RPD 05/23/14

Page 1

© 2007 Lokar, Inc.

General Installation Notes:

Please read instructions completely before beginning installation. If

you have any questions please call.

Before starting installation, use wheel chocks to block the vehicle's

wheels. Disconnect the negative battery cable before beginning

installation.

The Ford AOD Selector Shaft, Flange and Arm also requires installation of a

Lokar Kickdown Kit, available separately.

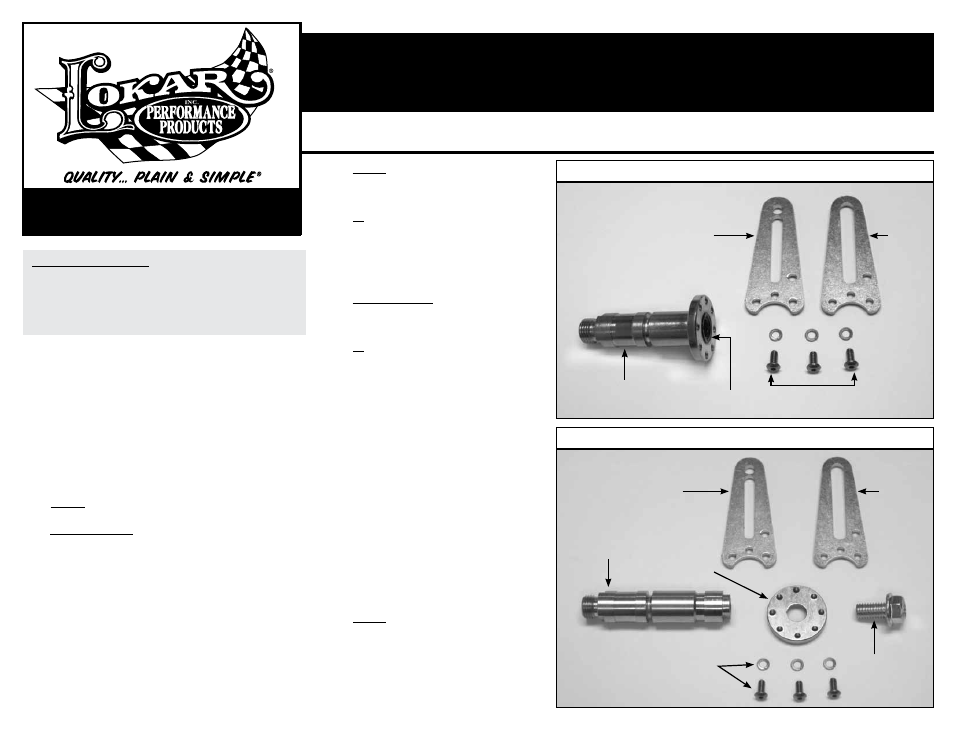

Refer to Fig. 1 and Fig. 2 for the component names.

NOTE: It will be much easier to install this product before the transmission is

installed in the vehicle, if possible.

The AOD (non-computer controlled) transmission has a Throttle Valve

(T.V.) shaft that passes through the center of the selector shaft. Parts

of these instructions and some of the photos will refer to the T.V. shaft,

a T.V. lever, and a T.V. spring.

These parts are not present in an AODE or

4R70W transmission.

Step 1: Put the transmission in Park by rotating the original trans arm

clockwise as far as it will go.

Step 2: AOD Only: Remove the nut and T.V. lever from the T.V. shaft in the

center of the selector shaft.

AODE and 4R70W Only: Remove the bolt or nut from the center

of the selector shaft, and remove the original trans arm.

NOTE: If

the new Lokar flange fits on your existing selector shaft, it is not

necessary to replace the selector shaft. If you are only installing

the Lokar Selector Shaft Flange and Arm and are not replacing the

selector shaft, skip to

Step 13.

Step 3: Drain the transmission fluid and remove the transmission pan and

filter.

Step 4: Remove the 1/8" diameter roll pin that is located just inside the

pan rail on the boss that the selector shaft slides through. The pin

protrudes about 1/8" beyond the boss. Use a pair of side cutters

to grab the roll pin and pry the pin out using the case as your

leverage point.

Fig. 3

Step 5: Remove the roller spring that holds the gear selector plate in each

gear position.

Fig. 4

Step 6: AOD Only: The T.V. spring keeps tension on the T.V.

shaft. Make sure you pay attention to how this spring

is positioned, in the event that the spring moves

during selector shaft removal.

Fig. 5.

All: Move the gear selector plate all the way to the

rear to put it into low gear. Hold the gear selector

plate with a box end wrench or other tool to keep it

from rotating, and unscrew the 14mm nut from the

end of the selector shaft. On the AOD transmission,

the nut will still be retained by the T.V. shaft and will

remain in the transmission.

Fig. 6 and Fig. 7

Step 7: AODE and 4R70W Only: Remove the Auto Trans Gear

Position Sensor from the outside of the transmission

case by removing the mounting bolts and sliding it off

of the selector shaft.

All: Remove the old selector shaft from the transmis-

sion by sliding it out of the bore. The gear selector

plate will stay in the transmission, and you may have

to tap on it or lightly pry on it to get it separated from

the selector shaft.

Step 8: Lubricate the selector shaft seal in the transmission

and the new Lokar selector shaft with a small amount

of transmission fluid or transmission assembly grease.

On the AOD only, also lubricate the T.V. shaft seal

that is inside the new selector shaft.

DO NOT remove

the T.V. shaft seal; it is not necessary to remove it for

installation of the selector shaft.

Slide the Lokar selector shaft into the transmission.

On AOD models, the T.V. shaft fits inside the selector

shaft.

Step 9: Align the two flats on the gear selector plate in the

transmission with the flats on the new selector shaft,

and install the selector shaft into the gear selector

plate.

Fig. 8 The gear selector plate has a pin attached

to it that must be positioned in the groove on the pis-

ton that protrudes from the valve body. This pin needs

to be in the groove before the 14mm nut is tightened.

Fig. 9 Once the pin is in the groove, tighten the nut.

AOD Only: If the T.V. spring slipped out of place, put

the spring back into position as shown in

Fig. 5. Also

verify that the internal T.V. lever is aligned with the

T.V. piston. With the external T.V. lever removed, it is

possible for the T.V. shaft and internal lever to slide

in too far, and the lever can get trapped between the

T.V. piston and the valve body.

Fig. 5 and Fig. 10

AOD Only

AODE and 4R70W

- OR -

- OR -

Fig. 1

Fig. 2

Selector Shaft

T.V. Shaft Seal

Trans Arm with

1/4" Slot and Hole

Selector Shaft

(not required or included

for models with factory

bolt-on trans arms)

Trans Arm with 1/4"

Slot and Hole

Trans Arm

with 5/16"

Slot

Selector Shaft

Flange

#8-32 x 3/8"

Button Head

Bolts and Lock

Washers

3/8"-16 x 3/4"

Lock Bolt

Trans Arm

with 5/16"

Slot

#8-32 x 3/8" Button

Head Bolts and Lock

Washers