Controller settings - channel tab – Ag Leader InSight Spinner Spreader User Manual

Page 11

Part No. 2002831-39 Rev. D

11

Section 8: Controller Settings

These settings are shown in Controller Settings window, accessed via the Controller

Settings button on the Controller Tab. These settings appear on the Channel Tab.

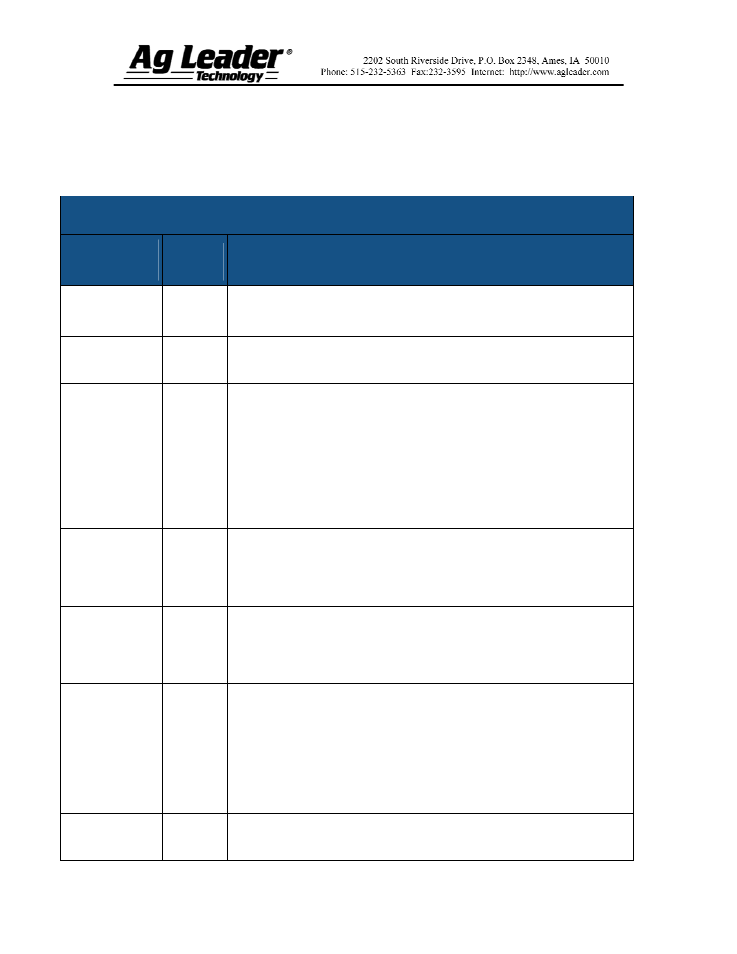

Controller Settings - Channel Tab

Setting

Name

Default

Setting

Description/characteristics

Shaft Speed

Cal

180

Calibration number representing the pulses that equal one revolution of

the rate control metering system.

Control Valve

Configuration

Servo

Setting specifies the type of control valve being used for the rate control

functions of the controlling system.

Response

Threshold

15

Determines where the control channel switches between using Valve

Response 1 and Valve Response 2 speed setting. Leaving all other valve

control settings at the default value and making a small adjustment to this

setting is usually all that is required to fine-tune system performance.

Decreasing this value will have the overall effect of speeding up

servo valve response.

Increasing this value will have the overall effect of slowing servo

valve response.

Valve

Response 1

40%

Determines the speed of the servo valve when product control error

exceeds the Response Threshold setting. Valve Response 1 represents the

fast speed of the servo valve. Decreasing the value will cause the servo

valve to run slower.

Valve

Response 2

8%

Determines the speed of the servo valve when product control error is less

than the Response Threshold setting. Valve Response 2 represents the

slow speed of the servo valve. Decreasing the value will cause the servo

valve to run slower.

Allowable

Error

2%

Determines the percent of error that is allowed prior to the product control

system making any flow rate changes. 2% - 3% is the normal dead band

setting range.

Too low of a setting value can cause the product control system to

continually hunt for the target application rate.

Too high of a setting will cause excessive product application

error.

Max Conveyor

Speed

60

Setting determines the maximum RPM of the conveyor that controls

product distribution to the application point.