Installing the ufm, F - ufm, 4installing the ufm – Dwyer UFM User Manual

Page 7

F - UFM

Issue 1.4

Page 7

4

Installing the UFM

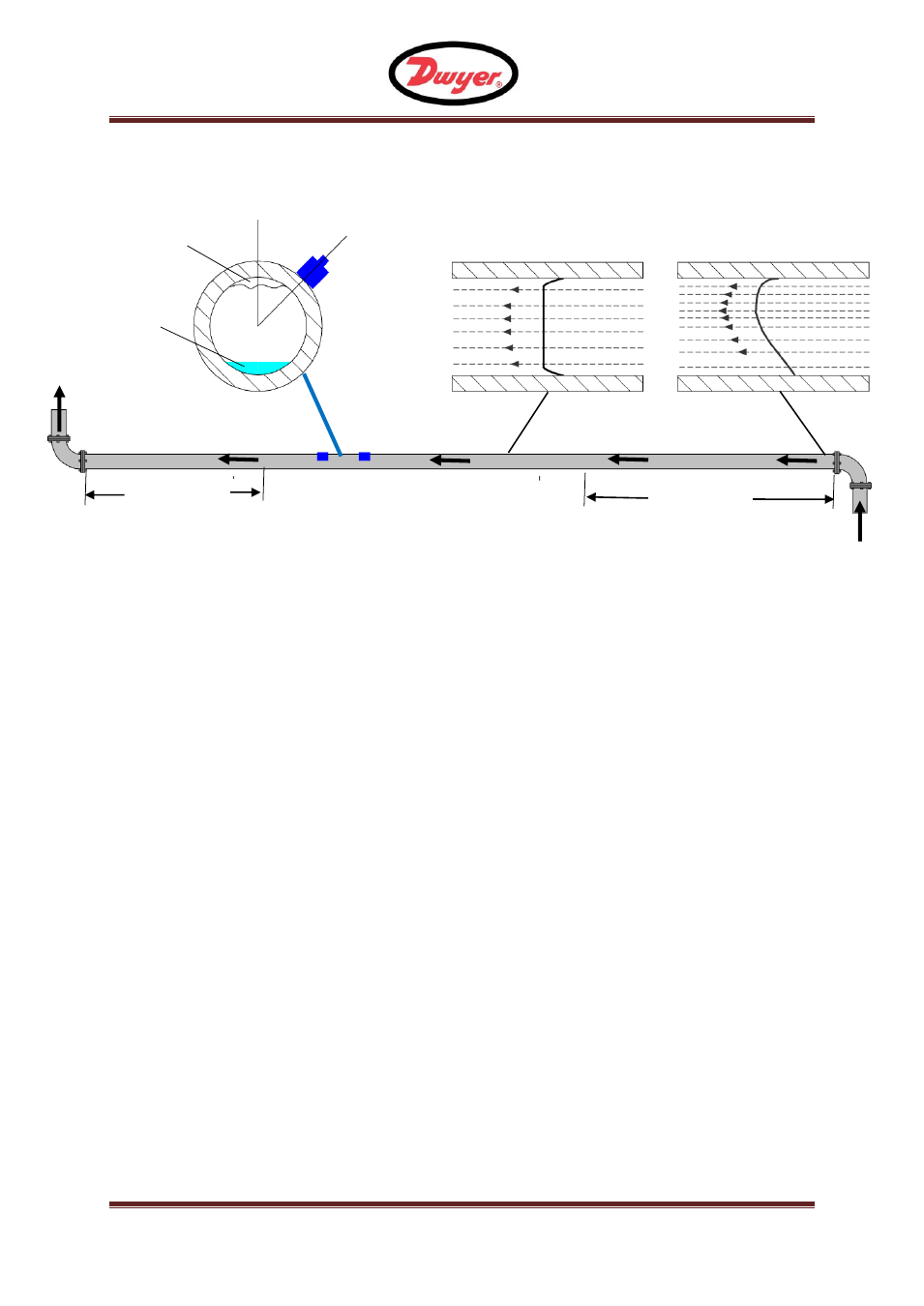

Figure 3 Location of Transducers

In many applications an even flow velocity profile over a full 360° is unattainable due to the

presence of air turbulence at the top of the flow and possibly sludge at the bottom of the pipe.

Experience has shown that the most consistently accurate results are achieved when the

transducer guide rails are mounted at 45° with respect to the top of the pipe.

The UFM equipment expects a uniform flow profile, as a distorted flow will produce

unpredictable measurement errors. Flow profile distortions can result from upstream

disturbance such as bends, tees, valves, pumps and other similar obstructions. To ensure a

uniform profile the transducers must be mounted far enough away from any cause of distortion

such that it no longer has an effect.

To obtain the most accurate results the condition of both the liquid and the pipe must be

suitable to allow ultrasound transmission along the predetermined path. It is important that

liquid flows uniformly within the length of pipe being monitored, and that the flow profile is not

distorted by any upstream or downstream obstructions. This is best achieved by ensuring

there is a straight length of pipe upstream of the transducers of at least 20 times the pipe

diameter, and 10 times the pipe diameter on the downstream side, as shown in Figure 3. Flow

measurements can be made on shorter lengths of straight pipe, down to 10 diameters

upstream and 5 diameters downstream, but when the transducers are mounted this close to

any obstruction the resulting errors can be unpredictable.

Key Point: Do not expect to obtain accurate results if the transducers are positioned close to

any obstruction that distorts the uniformity of the flow profile.

Possible Air

Possible

sludge

Guide

rail

Uniform Flow Profile

Distorted Flow Profile

Flow

Flow

Valid transducer location

20 x Diameter

10 x Diameter

45°