Blue-White FLEX-PRO A2 ProSeries Peristaltic Pump User Manual

Page 15

Page 15

Flex-Pro

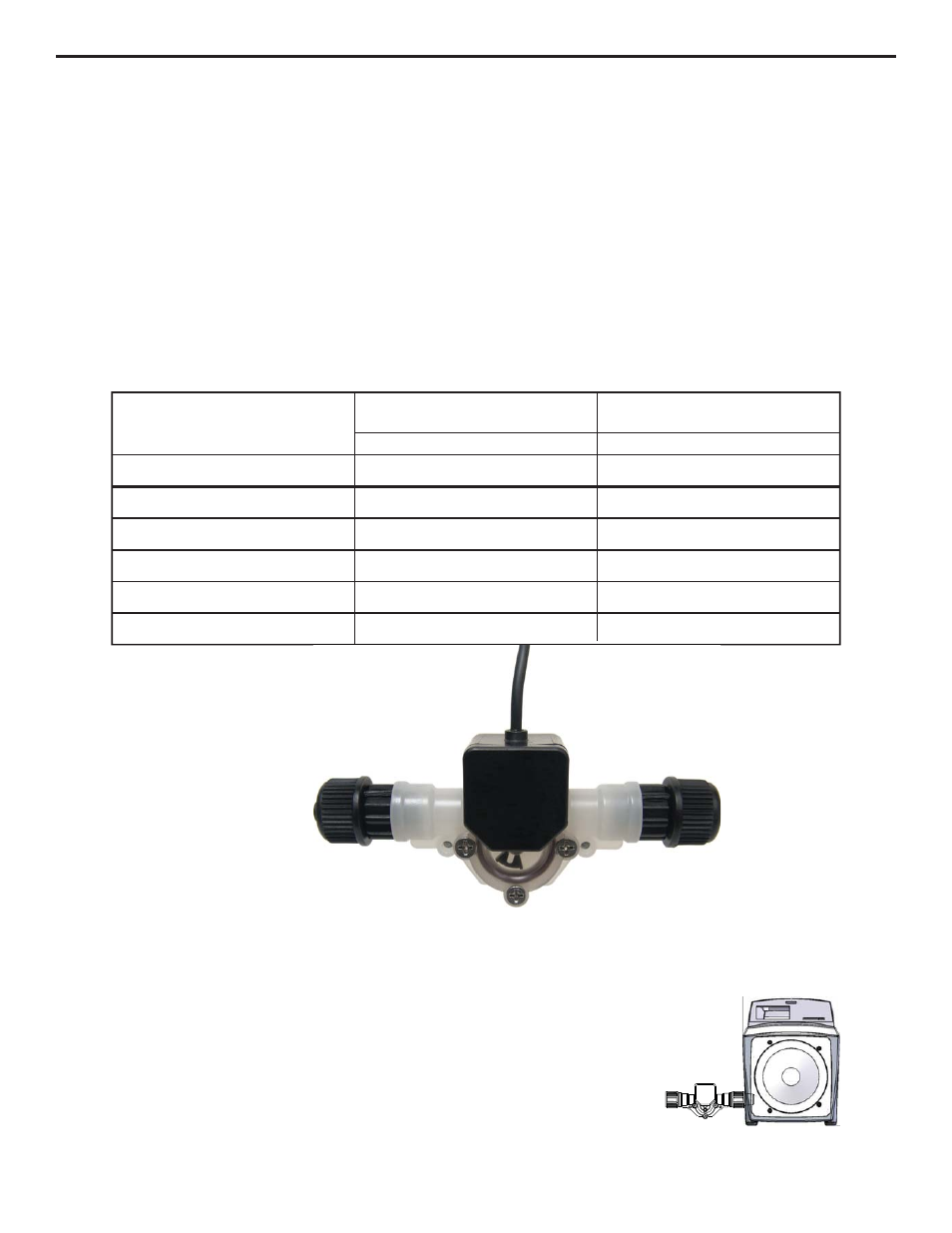

Flow Verification Sensor is designed to give you two installation options.

Sensor can be installed:

!

Directly on pumphead of A2 pump, suction side.

!

Anywhere on suction side of A2 pump.

Wiring for sensor can be connected directly to an A2 pump. Pump will stop pumping if sensor detects no flow. A

relay will then close allowing for remote alarm indication or initiation of a back-up injector pump.

Install FVS Flow

Sensor - Flow Verification Sensor should be installed on inlet (suction) side of pump tube. Sensor includes a PVC

tubing insert, located inside sensors female thread connection, that is designed to seal sensor onto pump tube

inlet adapter. Thread sensor onto pump tube until tubing insert is snug against pump tube inlet fitting - do not

over-tighten.

7.2

Mode 0 - Set FVS (flow verification system) - Continued

Sensor Model Number

Actual Working Range with

Flex-Pro Pump

ML/Min

ML/Min

30-200

FV-100

30-300

Published Flow Range

50-900

FV-200

100-1000

100-1800

FV-300

200-2000

300-3000

FV-400

300-3000

500-5000

FV-500

500-5000

700-7000

FV-600

700-7000

Confirm FVS flow range - Flow Verification Sensor (FVS) will only function

within its operating range. See chart for available ranges.

Example: Sensor model FV-100 has an operation range of 30-300 ml/min

when used as a flowmeter. However, due to pressure drop across sensor,

pump’s suction capability is limited to 14.7 psi. When used as a Flow

Verification Sensor with a peristaltic pump, effective operating range is

reduced to 30-200 ml/min.

NOTE: If pump output is less than 30 ml/min, sensor will not detect chemical

and a signal will not be sent to pump, resulting in an alarm condition.

NOTE: For low viscosity (water-like) fluids only. Consult factory if attempting

to use with viscous fluids.