Operation, Maintenance, Sbs50 boost – Blue Angel Pumps SBS50BOOST User Manual

Page 3

3

Operation

Unit must be full of

fl uid before

operating. Do not run dry or against a

closed discharge. Do not pump dirty water

or abrasive liquids. To do so will cause the

pump failure and will void the warranty.

VALVES

The inlet and outlet isolation valves

should be in the full open position.

PRIMING

NOTE: Before starting the pump it

is absolutely necessary that both

the pump and the inlet pipe be

completely fi lled with water.

PRESSURE BOOST INSTALLATIONS

Priming is automatic when pump is

connected to a pressure source such as a

hydrant or city main. (See Figure 3).

1. Open valves or nozzle on inlet and

discharge side of pump.

2. Open a faucet nearest the booster

unit. Plug pump into outlet. When

the water fl ow from the faucet

reaches one gallon per minute, or

greater, the pump will automatically

start. Keep the faucet open for

approximately 30 seconds to relieve

trapped air in the line. When the

faucet is closed, the pump will

continue to run until pressure

reaches 60 psi.

The pressure switch

is factory set at 50

psi and must not be changed.

3. If you installed a pressure gauge at

the pump inlet, a reading of 2 psi

minimum should show whenever the

pump is in operation. This reading

ensures that there is an ample supply

of water into the pump inlet housing.

4. The controller, fl ow sensor and

pressure switch continuously

monitor water pressure and fl ow.

The system automatically turns the

unit off if pressure reaches 50 to

53 psi. The control package also

protects the unit from dry run by

shutting down if water usage drops

below 1 gallon per minute.

MOTOR/PUMP ROTATION

1. The motor rotates in a counter

clockwise rotation when facing the

pump end and cannot be reversed.

START-UP PROCEDURE

Once the preceding instructions have

been completed, the unit is ready for

normal operation.

1. During the fi rst few hours of

operation, inspect the pump, piping

and any auxiliary equipment used in

connection with the unit for leaks,

excessive vibration or unusual noises.

2. The booster unit will turn on and

off automatically, based on water

usage.

Maintenance

Disconnect

power

and release all

pressure from the system before

attempting to install, service, relocate

or perform any maintenance. Lock the

power disconnect in the open position.

Tag the power disconnect to prevent

unexpected application of power.

Protect the pump

from freezing during

winter conditions.

DRAINING THE PUMP

Drain openings are provided on all

models. To drain the pump:

1. Remove drain plug and prime plug

to vent the system.

REMOVING OLD SHAFT SEAL

Turn disconnect switch

to “off” position.

1. Open a faucet nearest the tank and

allow all water to drain from the

tank.

2. Remove the four cap screws holding

the pump housing (volute) to the

motor (Figure 4).

www.blueangelpumps.com

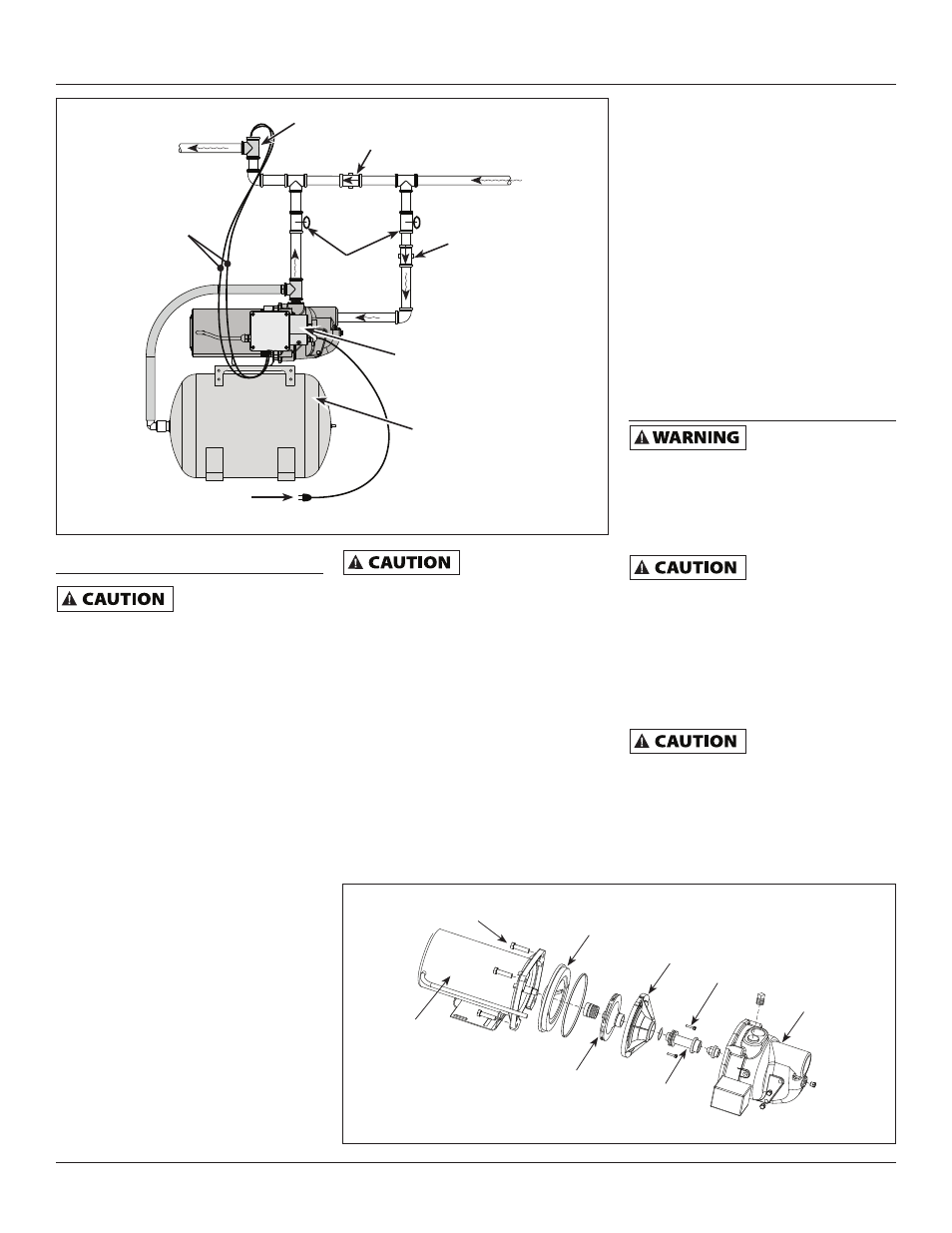

Municipal

Water

Flow

Switch

To Service

Isolation

Valves

Pressure

Switch

Tank

120 VAC Plug

Check Valve

Flow Switch

Connections

NOTE: “T”’s, Elbows,

and Isolation Valves

are not included

NOTE: Orient Flow Switch as indicated

Check Valve

Figure 3 - Typical installation

Cap Screws

Seal Plate

Diffuser

Cap Screws

Pump

Housing

(Volute)

Motor

Impeller

Venturi

Figure 4

Operating Instructions and Parts Manual

SBS50 Boost