Blue Angel Pumps SEF40D-2 User Manual

Sump / effluent pump, Description, Safety guidelines

This pump is intended for use in

domestic sump or effluent lift stations.

It is suitable for pumping effluent,

wastewater, ground water and other

nonexplosive, noncorrosive liquids

with up to 1/2" solids.

Sump /

effluent

pump will not pump raw sewage or

any substance exceeding 1/2” size.

This

pump is

not designed to handle salt water,

brine, laundry discharge, or any other

application which may contain caustic

chemicals and/or foreign materials.

Pump damage could occur if used in

these applications and will void

warranty.

Unpacking

Inspect this unit before it is used.

Occasionally, products are damaged

during shipment. If the pump or

components are damaged, return the

unit to the place of purchase for

replacement. Failure to do so could

result in serious injury or death.

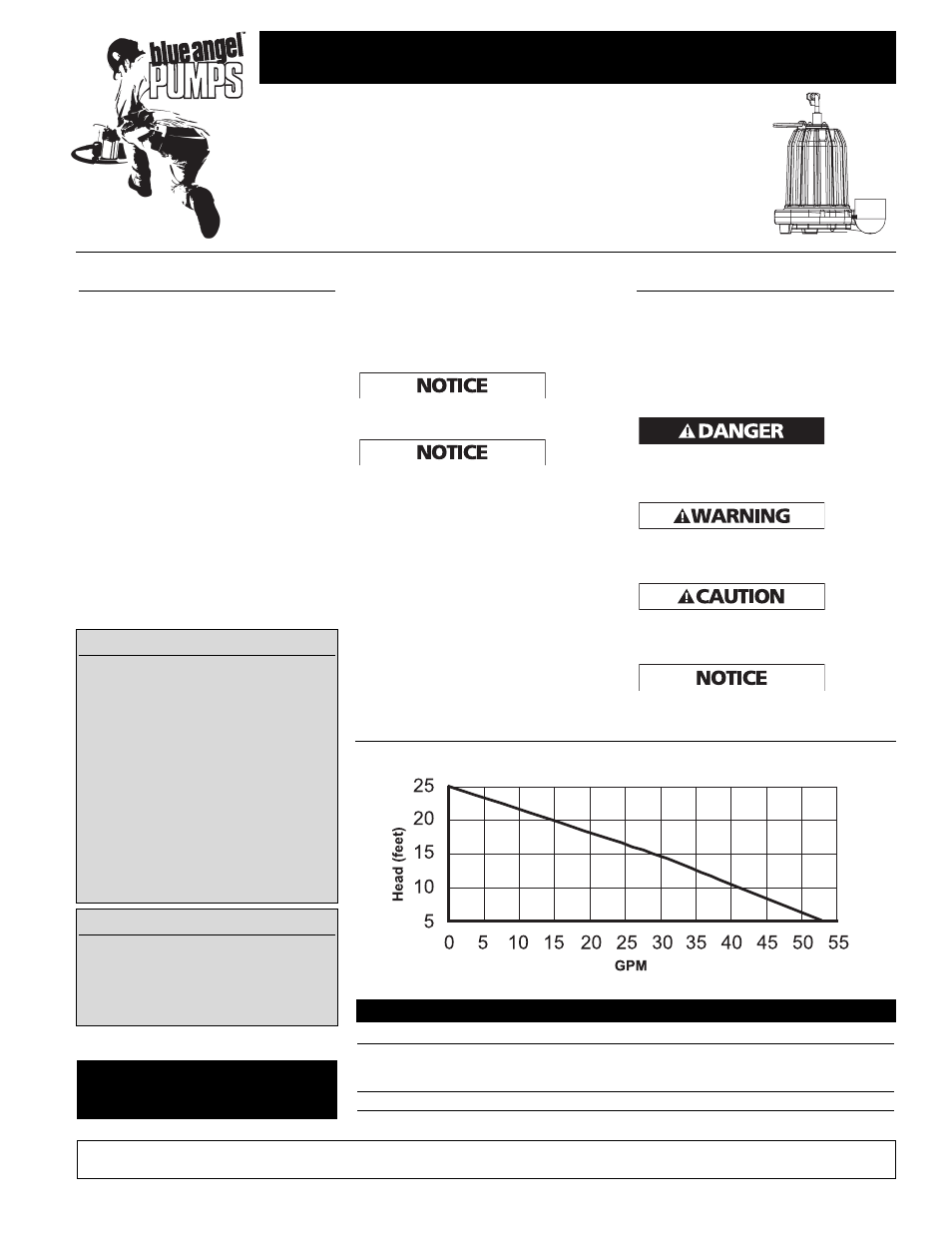

GALLONS PER MINUTE

AT TOTAL HEAD IN FEET

Model

10

15

20

25

SEF40

41

29

14

0

Please read and save these instructions. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by

observing all safety information. Failure to comply with instructions could result in

personal injury and/or property damage! Retain instructions for future reference.

Description

A sump/effluent system consists of a

pump, control switch and a basin.

The system may be controlled by a

float switch with one of the following

kinds of plugs:

Models SEF40D, SEF40D-2, SEF40V,

SEF40V-2, SEF40T, and SEF40T-2:

piggyback-style plug (which accepts

the pump plug) or

Model SEF40M: standard plug (which

uses internal wiring)

The system will use one of the

following kinds of switches:

Models SEF40V and SEF40V-2:

Vertical Mechanical Switch;

Models SEF40T and SEF40T-2:

Mechanical Float Switch; or

Models SEF40D and SEF40D-2:

Diaphragm Switch

Operating Instructions

SEF40V, SEF40V-2, SEF40T, SEF40T-2,

and Parts Manual

SEF40D, SEF40D-2, SEF40M

330405-002 12/07

© 2007 Blue Angel™ Pumps

The Professional’s Line

Sump / Effluent Pump

Rating

4/10 HP, 8.3 A

4/10 HP, 8.3 A

4/10 HP, 8.3 A

4/10 HP, 8.3 A

Switch

Vertical

90

o

Wide Angle Diaphragm

Manual

Mechanical

Mechanical

Switch

Operation

Switch

Float Switch

Cut-in level (factory set)

7.5"

12.5”

12"

—

Cut-out level (factory set) 3.5"

4”

4.5"

—

SEF40V

SEF40T

SEF40D

SEF40M

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

Safety Guidelines

This manual contains information that

is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger

indicates

an imminently hazardous situation

which, if not avoided, WILL result in

death or serious injury.

Warning

indicates

a potentially hazardous situation

which, if not avoided, COULD result in

death or serious injury.

Caution

indicates

a potentially hazardous situation

which, if not avoided, MAY result in

minor or moderate injury.

Notice

indicates

important information, that if not

followed, MAY cause damage to

equipment.

For parts, product & service information

visit www.blueangelpumps.com

Specifications

Power supply

requirements . . . . . . . . . . .120V, 60 hz

Circuit requirements . . . . .15 amps (min)

Motor duty . . . . . . . . . . . .Intermittent

Motor . . . . . . . . . . . . . . . .120V, 1 Phase,

3000RPM

Liquid temperature

range . . . . . . . . . . . . . . . . .40°F to 125°F

Max. operating position . .45

o

from

vertical

Dimensions . . . . . . . . . . . .9" x 10"

Discharge . . . . . . . . . . . . . .1-1/2"

Power cord . . . . . . . . . . . .18 gauge

3 conductor

w/plug

Construction

Pump housing................Cast iron

Impeller..........................Glass reinforced

ABS

Inlet Cover .....................Stainless Steel

Shaft seal .......................Rubber Shaft Seal

Performance

Performance Curve