General safety information, Installation, Electrical – Blue Angel Pumps SBS50BOOST User Manual

Page 2: Continued), Sbs50 boost

2

Risk of electrical

shock. This pump is

designed for indoor installation only.

All wiring should

be performed by a

licensed or certifi ed electrician.

10. For safety, the unit must be

connected to a grounded circuit

equipped with a ground fault

interrupter device.

11. Before installing the pump, have the

electrical outlet checked by a licensed

or certifi ed electrician to make sure

the outlet is properly grounded.

12. Make sure the line voltage and

frequency of electrical current supply

agrees with the motor wiring.

Do not attempt to

use product at 240

volt. Only 120 volt is allowed.

13. Do not attempt repairs to the electric

motor. All repairs to the motor

must be completed at a licensed or

certifi ed electrical motor repair shop.

Do not touch an

operating motor.

Modern motors are designed to operate

at high temperatures.

14. Avoid kinking electrical cord and protect

from sharp objects, hot surfaces, oil and

chemicals. Replace or repair damaged or

worn cords immediately.

Disconnect power and release all

pressure from the system before

attempting to install, service, relocate

or perform any maintenance. Lock the

power disconnect in the open position.

Tag the power disconnect to prevent

unexpected application of power.

15. Keep

fi ngers and foreign objects away

from ventilation and other openings. Do

not insert any objects into the motor.

Risk of electric shock!

Never connect the

green (or green and yellow wire) to a

live terminal!

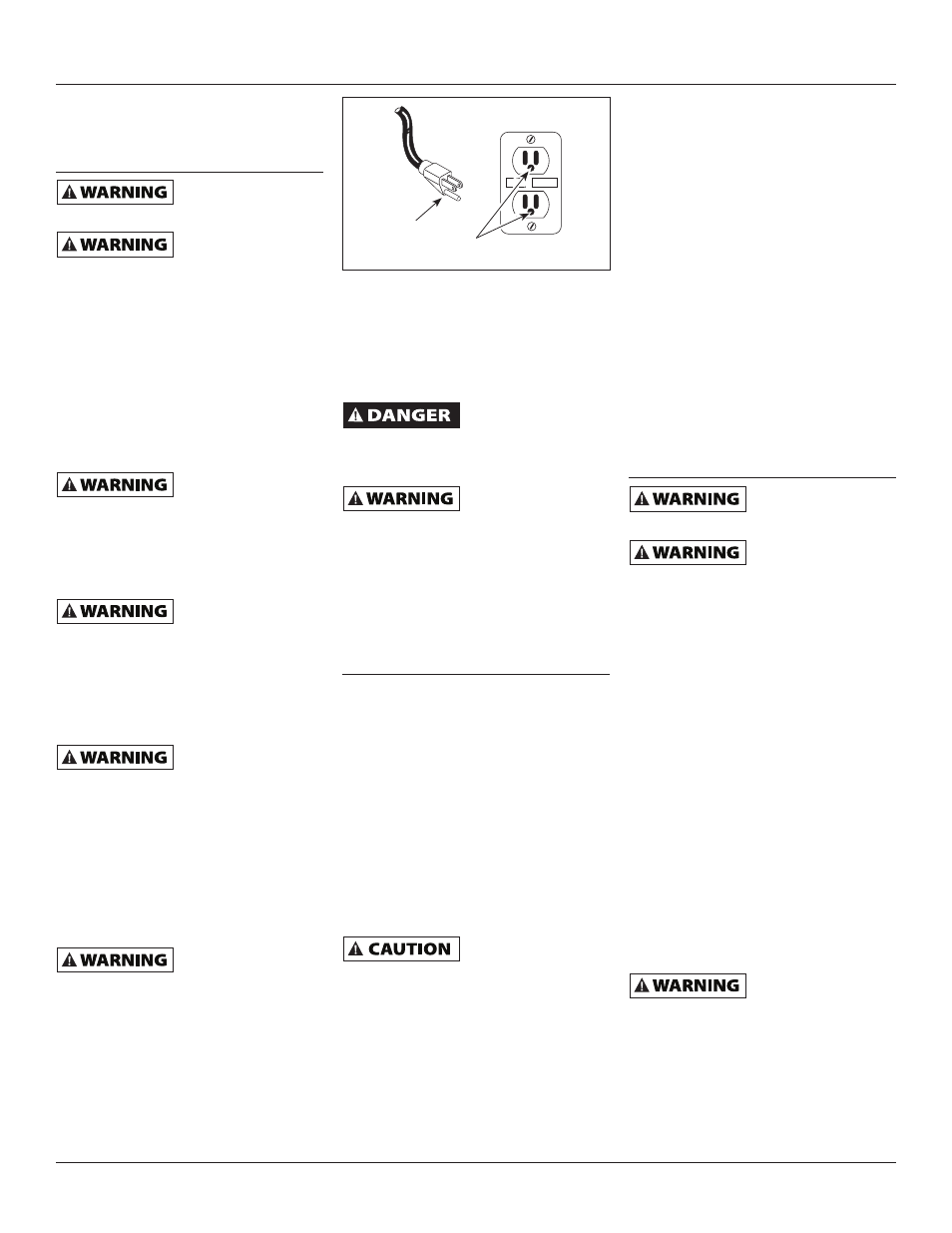

16. To reduce the risk of electrical shock,

the pump should be plugged directly

into a properly installed and grounded

3-prong grounding type receptacle, as

shown in Figure 2. The green (or green

and yellow) conductor in the cord is

the grounding wire. The motor must

be securely and adequately grounded

for protection against shock.

General Safety

Information

(Continued)

17. Where a 2-prong is encountered,

replace the plug with a properly

grounded 3-prong receptacle in

accordance with the National Electrical

Code, local codes and ordinances.

To ensure a proper ground, the

grounding means must be tested by a

licensed or certifi ed electrician.

Do not handle pump

or pump motor with

wet hands, when standing on a wet or

damp surface or when standing in water.

Fatal electrical shock could occur.

Pump motor is

equipped with an

automatic resetting thermal protector

and may restart unexpectedly. Protector

tripping is an indication of motor

overloading because of operating pump

at low heads (low discharge restriction),

excessively high or low voltage,

inadequate wiring, incorrect motor

connections or defective motor or pump.

Installation

LOCATION

Select a location as close to the water supply

as possible. Be sure to comply with any state

or local codes regarding the placement

of the pump. The equipment must be

protected from the elements. A basement

or heated pump house is a good location.

Make sure the pump has proper ventilation.

The temperature surrounding the pump

is not to exceed 100°F (40°C) or nuisance

tripping of the motor overload may occur.

PIPING

Piping may be copper, steel, rigid PVC

plastic or fl exible polyethylene plastic.

Flexible pipe is not

recommended on

suction pipe (inlet pipe). Flow sensor is

designed for 1” NPT connection.

The pipe must be clean and free of rust or

scale. Apply Tefl on

®

thread tape or sealant

to the 1” male NPT pipe threads and install

the switch into the piping system. Thread the

fl ow switch onto the male pipe thread until

hand-tight. Tighten pipe 1 additional turn. If

improper seal results, continue turning pipe

into unit 1/4 turn increments. Do Not Exceed

1 Additional Turn All connections must be air

tight to insure normal operation.

TEST

RESET

Grounded

Pin

Grounded Outlet

Figure 2

Slope all inlet piping upwards towards

the pump to prevent trapping air.

IMPORTANT: Pump is built to handle

clear water only; it is not designed to

handle water containing sand, silt or

other abrasives.

1. Refer to Figure 3 for typical

installations.

2. Bolt pressure booster system to a

secure foundation.

3. Locate the pump so that there will

always be a positive supply of water

to the pump (See Figure 3).

4. For service convenience, the installer

is recommended to add gate valves

and unions as needed to provide for

easier maintenance.

5. Pressure gauges on the inlet and

outlet, provided by the installer, are

recommended to show if suffi cient

water is being supplied to the pump

and to show service pressure.

Electrical

Risk of electrical

shock. This pump is

designed for indoor installation only.

Disconnect power

and release all pressure from the system

before attempting to install, service,

relocate or perform any maintenance.

IMPORTANT: Do not use an extension

cord or splice wires. Joints should be

made in an approved junction box. If the

above information is confusing, consult

a licensed electrician.

Your unit is supplied with a pressure

switch, fl ow sensor and a control box.

The only wire connection needed is to

plug the two red wires from the control

box into the two red wires on the fl ow

sensor (See Figure 3).

MOTOR PROTECTION

This motor has built in thermal protection.

The overload protects the motor against

burnout from overload of low voltage,

high voltage and other causes. The device

is automatic and resets itself once the

temperature has dropped to a safe point.

Frequent tripping of the device indicates

trouble in the motor or power lines and

immediate attention is needed.

Never

examine,

make wiring changes

or touch the motor before disconnect-

ing the main electrical supply switch.

The thermal device may have opened the

electrical circuit. The pump motor should

be equipped with a correctly fused discon-

nect switch to provide protection. Consult

local or United States National Electrical

Codes for proper fuse protection.

www.blueangelpumps.com

Operating Instructions and Parts Manual

SBS50 Boost