3 set-point processing 49, 1 set-point gradient / ramp 49, 4 switching behaviuor – West Control Solutions N8800 User Manual

Page 49

4.4 Switching behaviuor

With 8800 process controller, configuration parameter CYCL (ConF/ Cntr/

CYCL) can be used for matching the cycle time of 2-point and 3-point

controllers. This can be done using the following 4 methods.

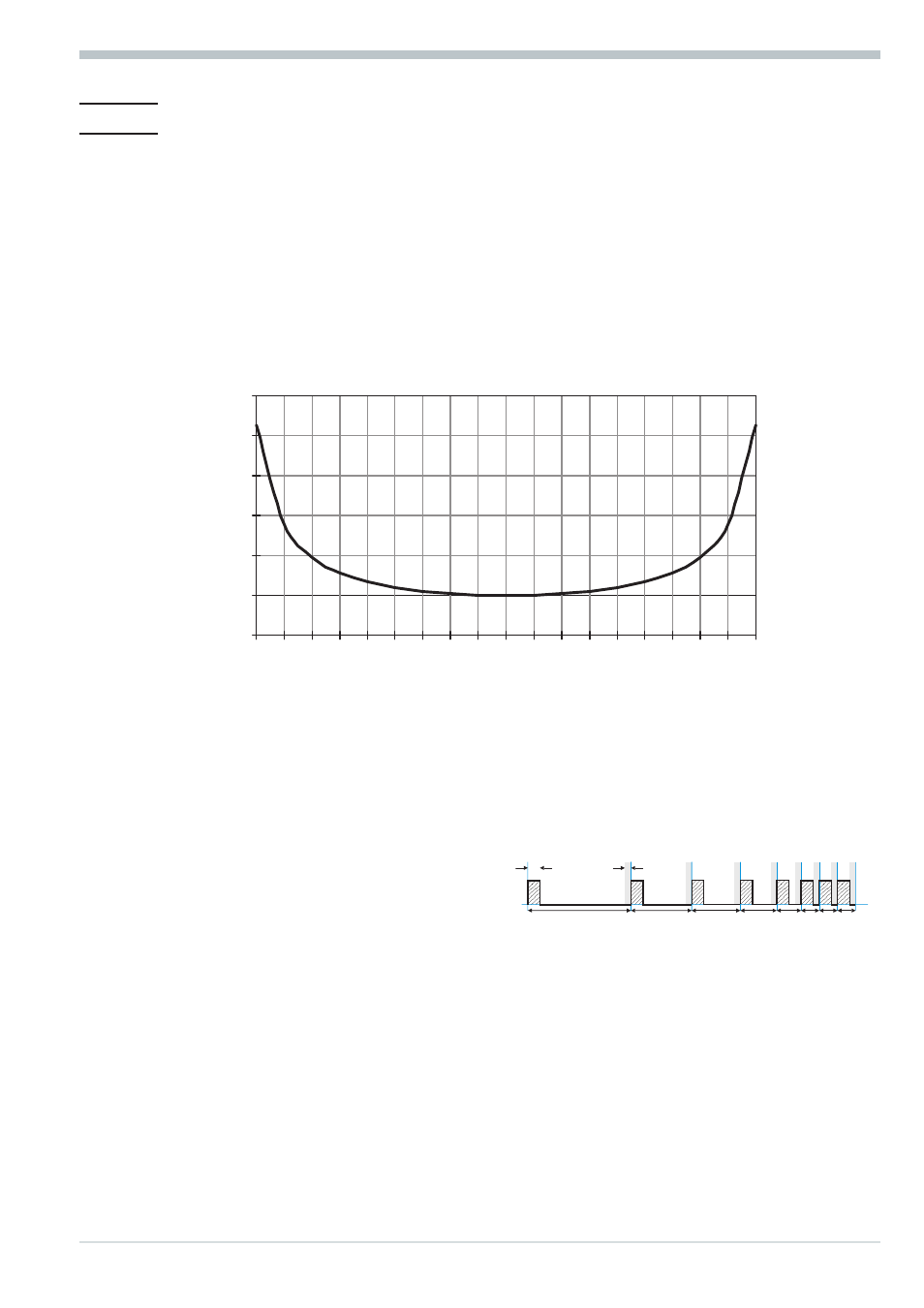

4.4.1 Standard ( CyCl= 0 )

The adjusted cycle times t1 and t2 are valid for 50% or -50% correcting

variable. With very small or very high values, the effective cycle time is extended

to prevent unreasonably short on and off pulses. The shortest pulses result from

¼ x t1 or ¼ x t2. The characteristic curve is also called “bath tub curve”

Parameters to be adjusted: t1 : min. cycle time 1 (heating) [s]

( PArA/ Cntr)

t2 : min. cycle time 2 (cooling) [s]

4.4.2 Switching attitude linear ( CyCl= 1 )

For heating (Y1), the standard method

(see chapter 4.4.1) is used. For

cooling (Y2), a special algorithm for

cooling with water is used. Generally,

cooling is enabled only at an

adjustable process temperature

(E.H2O), because low temperatures

prevent evaporation with related

cooling, whereby damage to the plant is avoided. The cooling pulse length is

adjustable using parameter t.on and is fixed for all output values.

The “off” time is varied dependent of output value. Parameter t.off is used for

determining the min “off” time. For output of a shorter off pulse, this pulse is

suppressed, i.e. the max. effective cooling output value is calculated according to

formula t.on / ( t.on + t.off) w 100%.

Configuration level

8800 process controller

49

Switching behaviuor

0,0

1,0

2,0

3,0

4,0

5,0

6,0

5

10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95

Controller output [%]

relative

cycle

duration

T / T

1

t1

2 x t1

3 x t1

4 x t1

-50% -67% -80% -100%

-30%

-20%

-10%

-6%

t.off

t.on