Cancelation 23 – West Control Solutions N8800 User Manual

Page 23

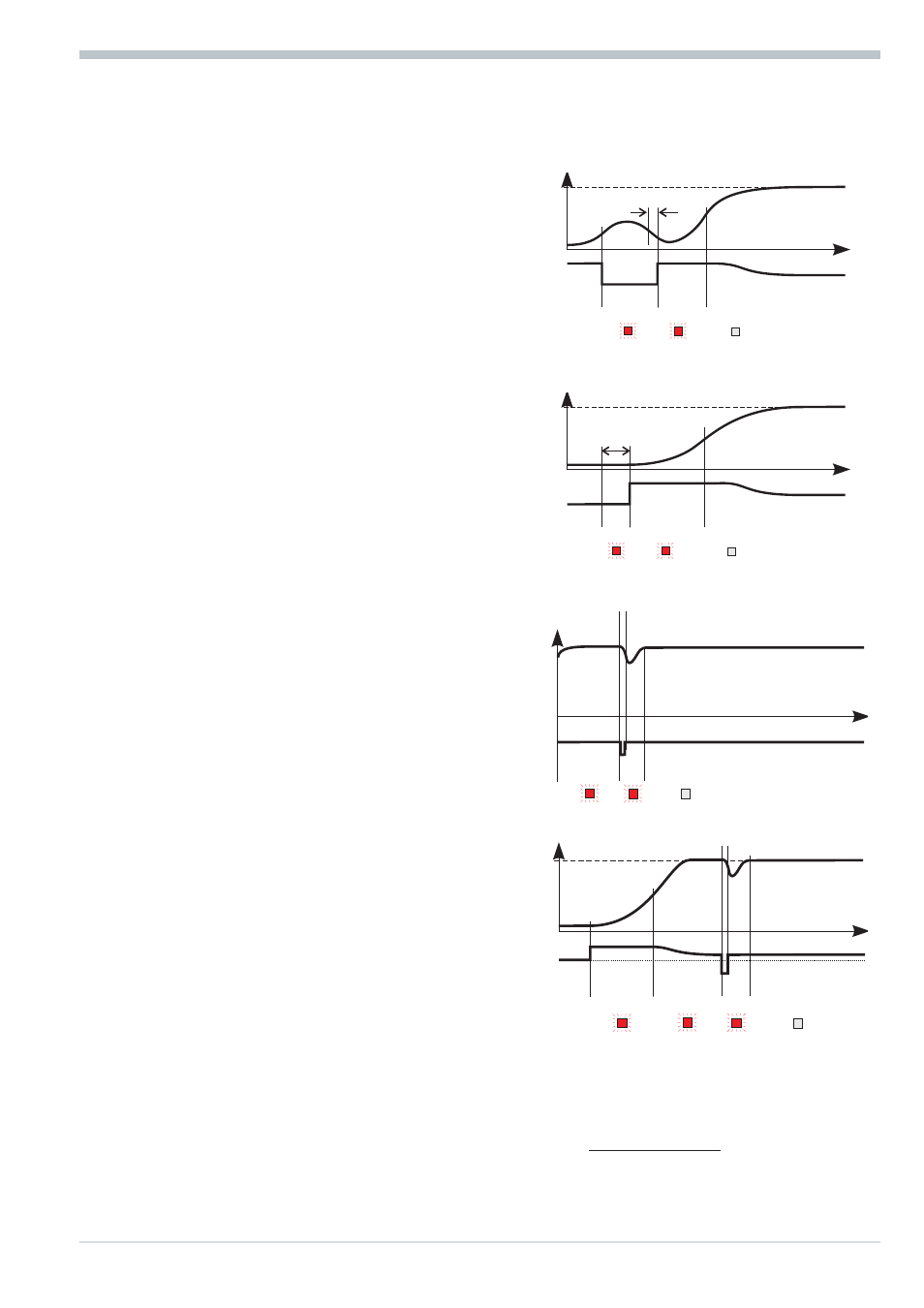

3.5.7 Examples for self-tuning attempts

(controller inverse, heating or heating/cooling)

Start: heating power switched on

Heating power Y is switched off (1).

When the change of process value X

was constant during one minute (2),

the power is switched on (3).

At the reversal point, the self-tuning

attempt is finished and the new

parameter are used for controlling to

set-point W.

Start: heating power switched off

The controller waits 1,5 minutes (1).

Heating power Y is switched on (2).

At the reversal point, the self-tuning

attempt is finished and control to the

set-point is using the new parameters.

Self-tuning at the set-point a

The process is controlled to the

set-point. With the control deviation

constant during a defined time (1)

(i.e. constant separation of process value

and set-point), the controller outputs a

reduced correcting variable pulse (max.

20%) (2). After determination of the

control parameters using the process

characteristic (3), control is started

using the new parameters (4).

Three-point controller a

The parameter for heating and cooling are

determined in two attempts. The heating

power is switched on (1). Heating

parameters Pb1, ti1, td1 and t1 are

determined at the reversal point. Control to

the set-point occurs(2). With constant

control deviation, the controller provides a

cooling correcting variable pulse (3).

After determining its cooling parameters

Pb2, ti2, td2 and t2 (4) from the

process characteristics , control operation is started using the new parameters (5).

a

During phase 3, heating and cooling are done simultaneously!

Operation

8800 process controller

23

Self-tuning

t

2

100%

Y

0%

X

W

Start r

1

3

t reversal point

blinks

t

100%

Y

0%

X

W

start r

1

2

t reversal point

blinks

t

2

100%

Y

0%

X

W

1

3

blinks

4

r t

Start r

t

+100%

Y 0%

-100%

X

W

t reversal

point

Start r

1

2

3

4

5

r t