7 troubleshooting – KROHNE OPTISONIC 7060 EN User Manual

Page 46

OPTISONIC 7060

Electrical & mechanical installation manual 730962.31.00 page 46 of 52

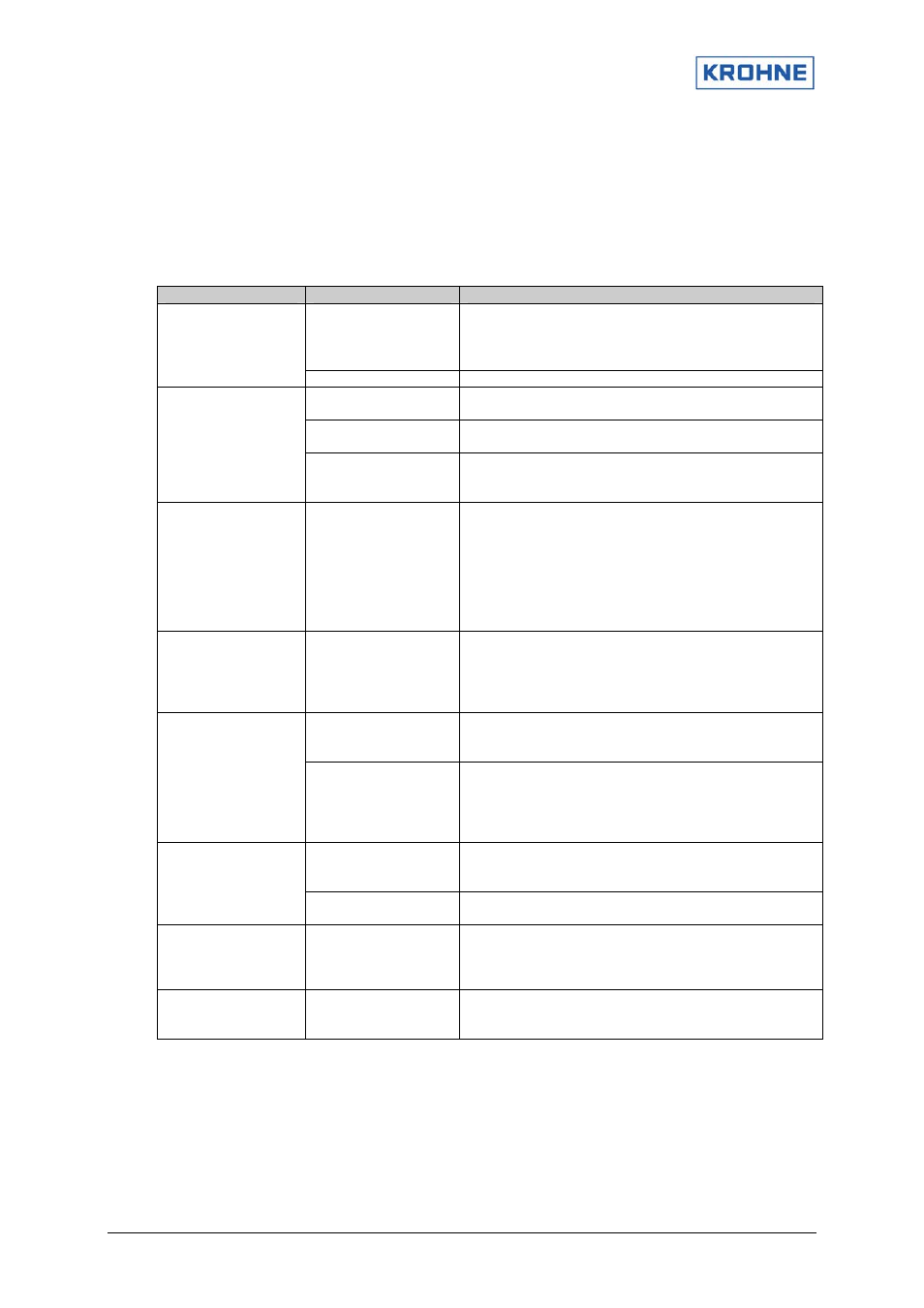

7 Troubleshooting

If the routine checks described in Section 5.2 or the functional checks described in Section

4.1.2

indicate that the device is not functioning properly, the following table will help you

diagnose the fault. If you still cannot find the cause for the fault, you can use the

ALTO IV program to carry out a more detailed fault diagnosis (see software manual, service

manual).

Display, parameter

Possible cause

Corrective action

Faulty power supply

• Check the input voltage at terminals 1 and 2

• Check cables and terminal connections

Important

Take the relevant safety precautions!

• No display

• No pulse frequency

• No active status

signal

Defective device

Contact the manufacturer

Transducer(s) are

dirty

Clean the transducer(s)

Transducer(s) are

defective

Replace the transducer(s) (see service manual)

“Warning” on the

LCD

Cabling swapped

when transducer was

cleaned

Check and, if necessary, correct

Different velocities of

sound in the

individual paths

Transducer or

electronics fault

Replace the transducer(s) (see service manual)

Note

Temperature stratification can result in differences

between the individual paths, especially with very low

flow (higher temperatures generate higher velocities of

sound). Even when the plant is being filled or when it is

shut down, different velocities of sound can occur on

the individual paths as a result of gas stratifications.

Implausible sound

velocity

Gas analysis,

pressure or

temperature

measurement

incorrect

Transducer(s)

damaged during

maintenance

Replace the transducer(s) (see service manual)

•

Lower signal-to-

noise ratio and

reception sensitivity

•

Increased number

of rejected

measurements in

individual paths

Additional sources of

noise due to a valve

that is not fully open,

fittings, noise sources

near the device

Check the measurement plausibility and number of

rejected measurements and, if necessary, remove

noise sources.

Different gas

composition or

process pressure

No work required on the device

Increased reception

sensitivity

Transducer(s) are

dirty

Clean the transducer(s)

Increased number of

rejected

measurements in all

paths

Additional noise

sources

Remove noise sources

Gas velocity outside

the measurement

range