3 menu c, setup, C1, process input a c2, process input b, Operation – KROHNE OPTISYS CL 1100 EN User Manual

Page 20

5

OPERATION

20

OPTISYS CL 1100

www.krohne.com

01/2013 - 4002492301 - MA OPTISYS CL 1100 R02 en

5.2.3 Menu C, setup

C1, process input A

C2, process input B

INFORMATION!

The signal converter has two process inputs, A and B. Each process input has an own submenu

in this main menu. Process input A is always present, i.e. there is always a board in the interface

"Pos.A" in the connection area. The interface of process input B only has a board with the two

channel signal converter. Be aware that the definition which kind of measurement a process

input can do is defined when ordering the device. The configuration cannot be changed later.

INFORMATION!

Note that the appearance of some submenus depends on the hardware setting and the used

sensor(s).

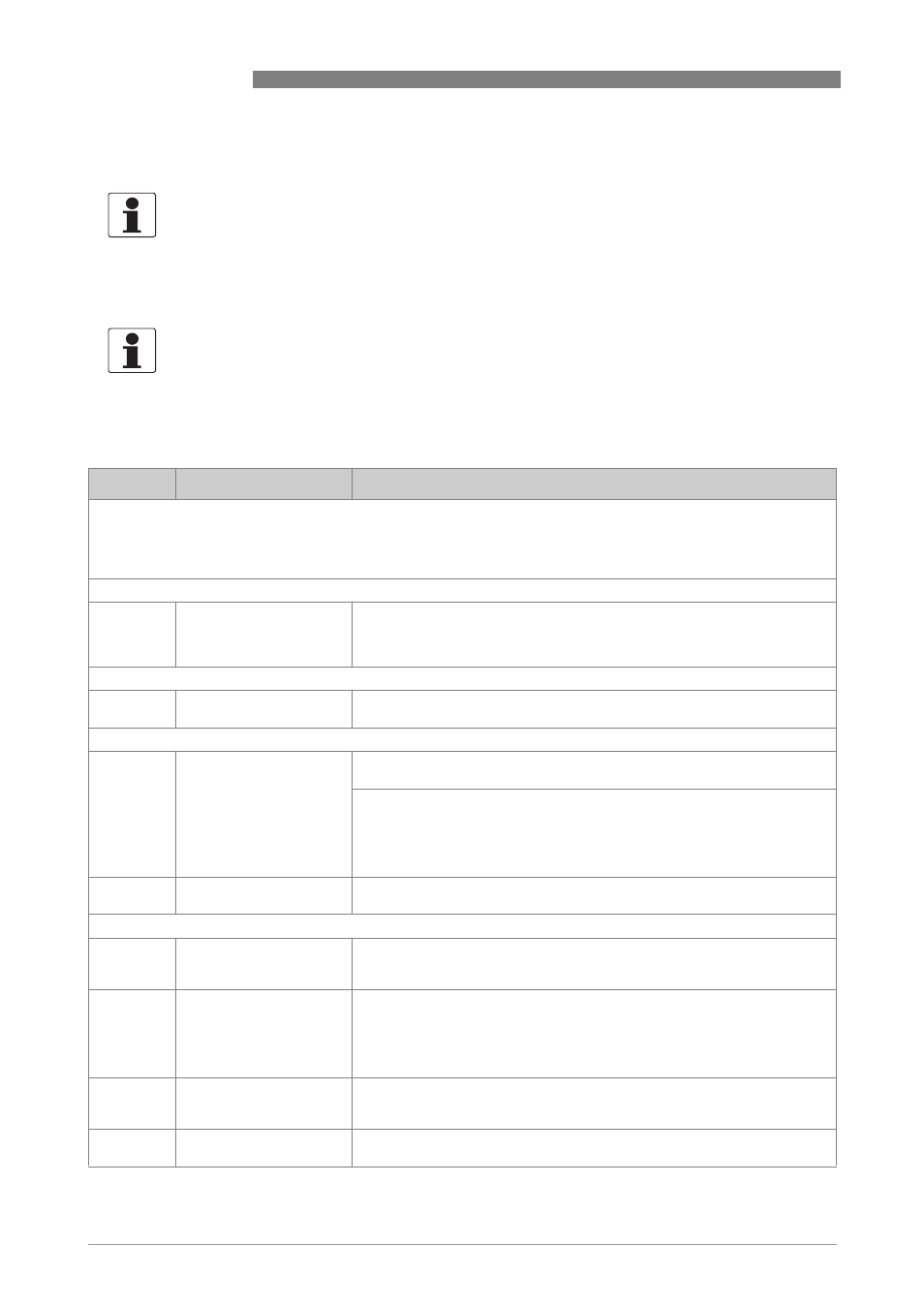

Level

Designation / function

Settings / descriptions

Process input A and B can be either a sensor 1 or a sensor 2. Further information about the type of sensor 1 or 2 please

refer to MAC 100 manual "Sensor input combinations". Process input A is always present, process Input B can be

present.

Note: The exchange of a sensors 1 with a sensor 2, or vice versa, can only be done by the manufacturer!

Depending on the sensor which is connected to a slot A or B the menu changes.

C1.1

parameter (Cl

2

/ClO

2

/O

3

)

This menu item is for selecting the probe which is connected to process

input A. The entries of this selection depends on the chosen device

configuration. The device configuration is customer specific and set during

production.

C1.9

slope

This menu item is read only.

It is used for the calibration procedure.

C1.11

pH compensation

The pH compensation menu is used for calibration of the pH sensor. For

detailed information refer to

pH compensation

on page 25.

Options:

•

off (default setting): pH compensation is disabled

•

manual: pH influences are compensated with manually entered values

•

automatic: pH influences are compensated automatically using the value

from a pH sensor which is connected to input B

C1.12

man. pH compensation

If in menu C1.11 the pH compensation was set to manual, here the desired

pH value is entered manually.

C1.13

cleaning

In this menu the cleaning parameters are set.

For detailed information and the cleaning procedure refer to

Cleaning

on

C1.13.1

cleaning

Options:

•

off: cleaning is disabled

•

24h period: cleaning is performed every 24 hours. (once a day)

•

12h period: cleaning is performed every 12 hours.

•

8h period: cleaning is performed every 8 hours.

C1.13.2

start time

Time:

Time of day: cleaning is started at manually entered time.

The start time of the cleaning procedure can be postpone.

C1.13.3

clean hold [s]

Hold time [s] after cleaning. If measurement after cleaning has not

approximated to 10% of old value, hold time is retriggered up to two times.