Testing the duct smoke detector, Replacement parts, Cleaning the duct smoke detector – Edwards Signaling E-PDD User Manual

Page 4: Wiring

4 / 6

P/N 3101210 • REV 02 • ISS 28JAN13

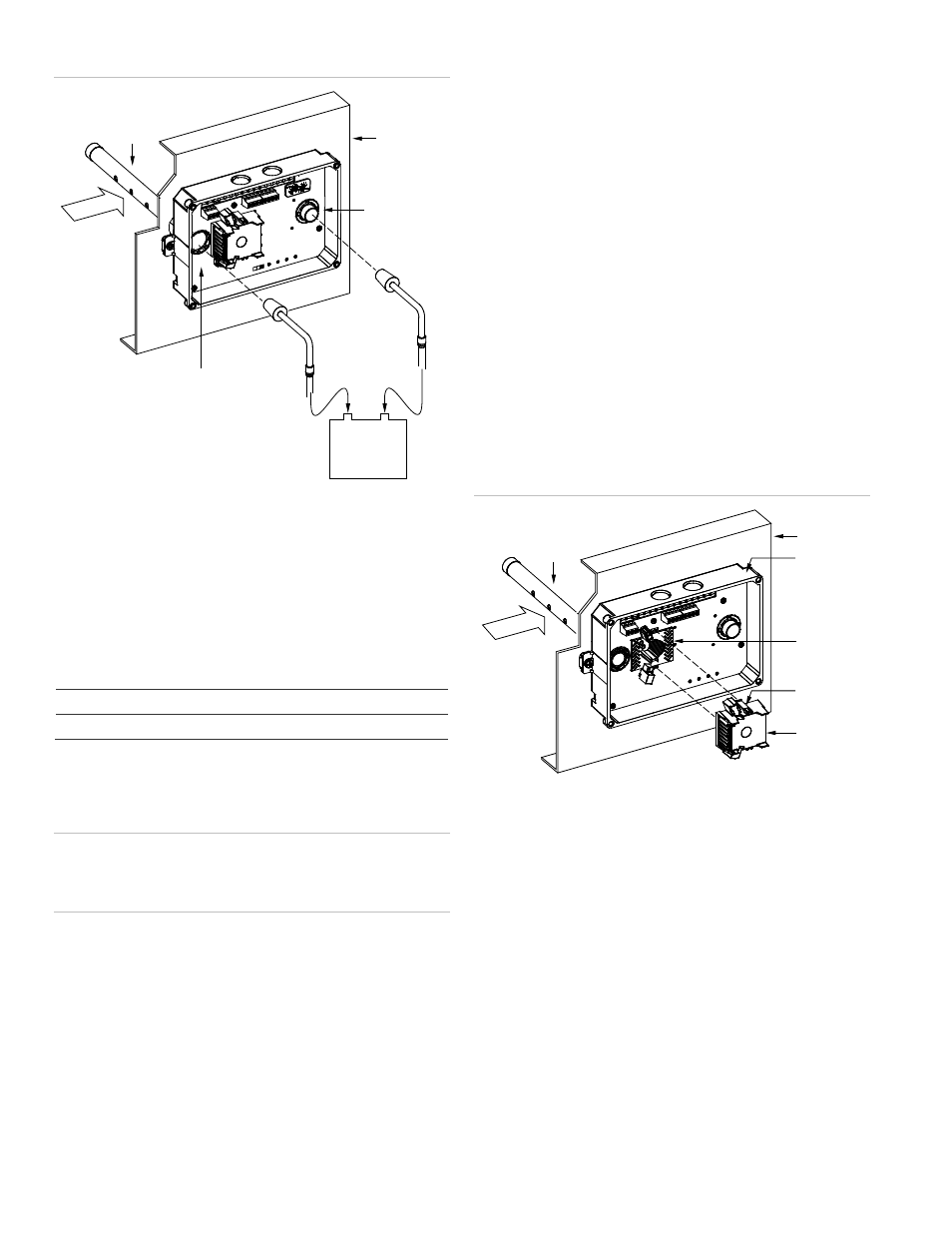

Figure 7: Air pressure differential

Airflow

Sampling tube

opening

Exhaust tube

opening

HVAC duct

Sampling

tube

Air pressure

differential

meter

Testing the duct smoke detector

After completing installation of the duct smoke detector, test

the detector to ensure it is operating correctly prior to leaving

the site. For details, refer to Technical Bulletin P/N 3101212.

Replacement parts

The following table lists the replacement parts for the duct

smoke detector.

Model

Description

E-SDPCB

PCB replacement kit for duct smoke detector

Cleaning the duct smoke detector

Clean the duct smoke detector when it becomes 80% to 99%

dirty or sooner if conditions warrant.

Caution:

Before cleaning the duct smoke detector, notify the

proper authorities that the fire alarm system is undergoing

maintenance and take steps to prevent the control panel from

responding to a false alarm.

To clean the duct smoke detector:

1. Disable the detector/zone to prevent false alarms.

2. Remove the detector’s cover then power down the

detector by disconnecting the SLC wiring.

3. Using a vacuum cleaner, clean compressed air, or a soft

bristle brush, remove loose dirt and debris from inside the

detector housing and cover.

4. Remove dirt and other contaminants from the gasket on

the detector’s cover using isopropyl alcohol and a lint-free

cloth.

5. Squeeze the retainer clips on both sides of the optic

housing then lift the housing away from the printed circuit

board.

6. Gently remove dirt and debris from around the optic plate

and inside the optic housing.

7. Replace the optic housing and detector cover, and then

connect the SLC wiring.

8. Test the detector and verify sensitivity. For details, refer to

Technical Bulletin P/N 3101212.

Figure 8: Duct detector cleaning

Airflow

HVAC duct

Sampling

tube

Retainer

clip

Optic

plate

Optic

housing

Detector

housing

Wiring

Wire in accordance with NFPA 72 and CAN/ULC-S524. Be

sure to observe the polarity of the terminals on the terminal

block as shown in Figure 9.