Edwards Signaling 101XBRM Series User Manual

Page 2

P/N 3101631 ISSUE 3

b. Direct Surface Mounting (indoor installation only)

Remove the two knockouts from the bottom of the

base.

Fasten the base to the surface using suitable

hardware (not supplied).

c. 4" (102 mm) Octagon Box Mounting (indoor

installation only)

Remove the two knockouts from the bottom of the

base.

Fasten the base to the octagon box (not supplied) by

installing the screws (supplied with the box) through

the knockout holes in the base.

d. Conduit Mounting (indoor or outdoor installation)

Install a 1/2" NPT conduit (not supplied). Align the

conduit entrance hole on the base with the conduit

and rotate base until base is tightly secured.

2. Route incoming field wiring into the base through the

conduit entrance hole.

Up to five 101XBRM LED modules or any other modules

shown in Table 2 can be used in any position in the stack.

The terminal block labels, 1 through 5, correspond to the

stacked modules with 1 being the bottom module on the

stack.

Connect field wiring to the terminal block as shown in

Figure 4.

Ground the AC AdaptaLights to the grounding screw

(Figure 3) in accordance with applicable codes. Place

the connected wires inside of the base.

Assemble the base unit and place the base gasket on

top as shown in Figure 2.

3. To stack the modules, align the notch on the bottom of

the first module with the notch on the base and press

into position. Secure by tightening the slotted panhead

through-bolt located on the top of the module.

NOTE: Never try to remove the through-bolt from the

module.

Install the #8-32 x 3/8" (9.5 mm) plastic panhead

screw in the side of the module lens (Figure 5).

Place gasket supplied with module onto the top of

the module.

Continue adding modules in this manner as required.

Place the cap supplied with the base unit onto the top

module ensuring the gasket is in place. Secure with

an o-ring and 3/8" (9.5 mm) cap screw (supplied).

4. Turn on power and verify that module(s) and horn

are operating properly.

Maintenance/Flash Pattern Change

Refer to "Specifications" for replacement parts.

WARNING

To prevent electrical shock, disconnect all

power before starting work on unit.

1. Remove the 3/8" (9.5 mm) cap screw, o-ring and cap

from top of unit.

2. Remove the #8-32 x 3/8" (9.5 mm) plastic panhead screw

from the side of the module lens.

3. Loosen the slotted panhead through-bolt (on top module).

Do not remove the through-bolt from the module; turn

the bolt approximately 30 turns.

4. Carefully remove the module and gasket.

5. Continue to disassemble until the internal dipswitch on

the top circuit is reached or the component to be replaced

is located. To change the flash pattern, set the dipswitch

as illustrated in Figure 6. To replace the pulsating horn,

follow instructions shown below.

6. Replace mini pulsating horn.

a. Remove the screw in the clamp ring, remove ring

and set aside.

b. Remove three phillips head screws from top of base

skirt and the base/horn assembly from the top portion

of the base (Figure 2).

c. Remove the phillips head screw securing the horn

to the mounting bracket (Figure 2).

d. Disconnect wires by cutting off the wire crimp

connectors.

e. Secure the new horn on the mounting bracket with

the screw removed in step 6.c.

f. Connect wires using wire nuts (not supplied).

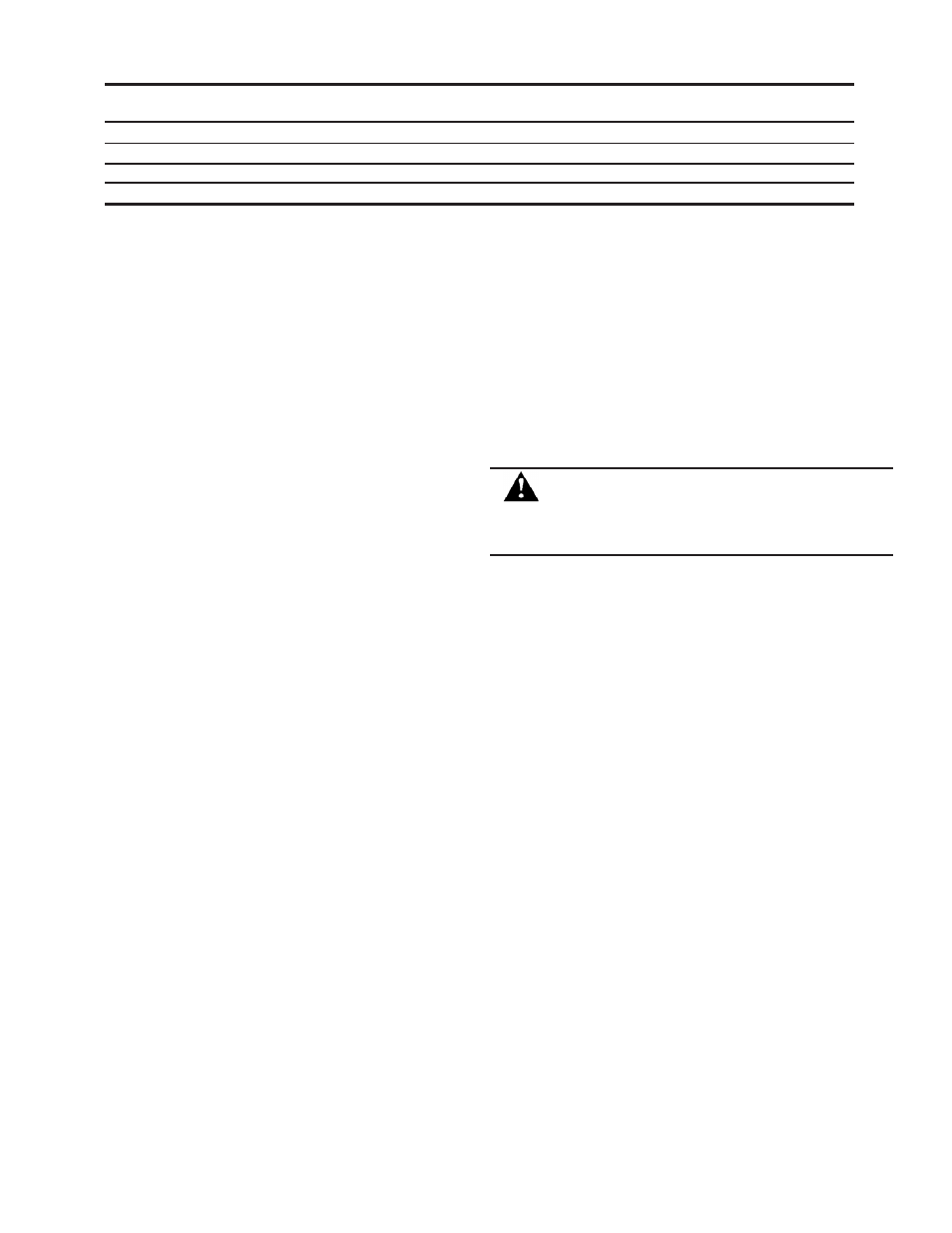

Table 1. PLC Compatibility

Operating

Maximum off state

Continuous on

Cat. No.

voltage*

leakage current (mA)

current (mA)

Surge (inrush/duration)

101BS-G1

24V DC

1.2

20

2/1 A/millisecond

101BS-N5

120V AC

25

50

2/1 A/millisecond

101XBRM( )24D

24V DC

5

215

34.5/52 A/microsecond

101XBRM( )120A

120V AC

5

108

37.5/164 A/microsecond

*All AC volts at 50/60 Hz