Hired-Hand Farm Hand Series: SC-5v2 User Manual

Page 13

Part No. 4801-5324 Rev 9-05

Farm Hand SC-5v2 5 Stage

13 of 40

6.1.4 Stage On Temperature (P4)

The OnPoint (Max. On Point) setting is the temperature at which a stage turns on. (i.e. the

temperature at which a start signal is transmitted by the controller). The OnPoint setting of a

'cool' stage will always be greater than the target temperature. The OnPoint setting of a 'heat'

stage will always be less than the target temperature. The temperature controller will

automatically limit settings accordingly.

6.1.5 Stage Off Temperature (P5)

The OffPoint (Min. On Point) setting is the temperature at which a stage turns off.

6.2 Variable/Cool Timer

The following parameters are used to program only the variable stages on the Farm Hand SC-5v2.

The following sections explain each parameter in detail.

P10 = Min. Runtime Percentage

P11 = Motor Curve Selection

6.2.1 Minimum Runtime Percentage (P10) (Variable Stages Only)

This setting is the percentage of the system timer that the variable stage will run at minimum

speed if the stage sensor's temperature is below the Minimum OnPoint (OFF) for the stage.

6.2.2 Motor Curve Selection (P11) (Variable Stages Only)

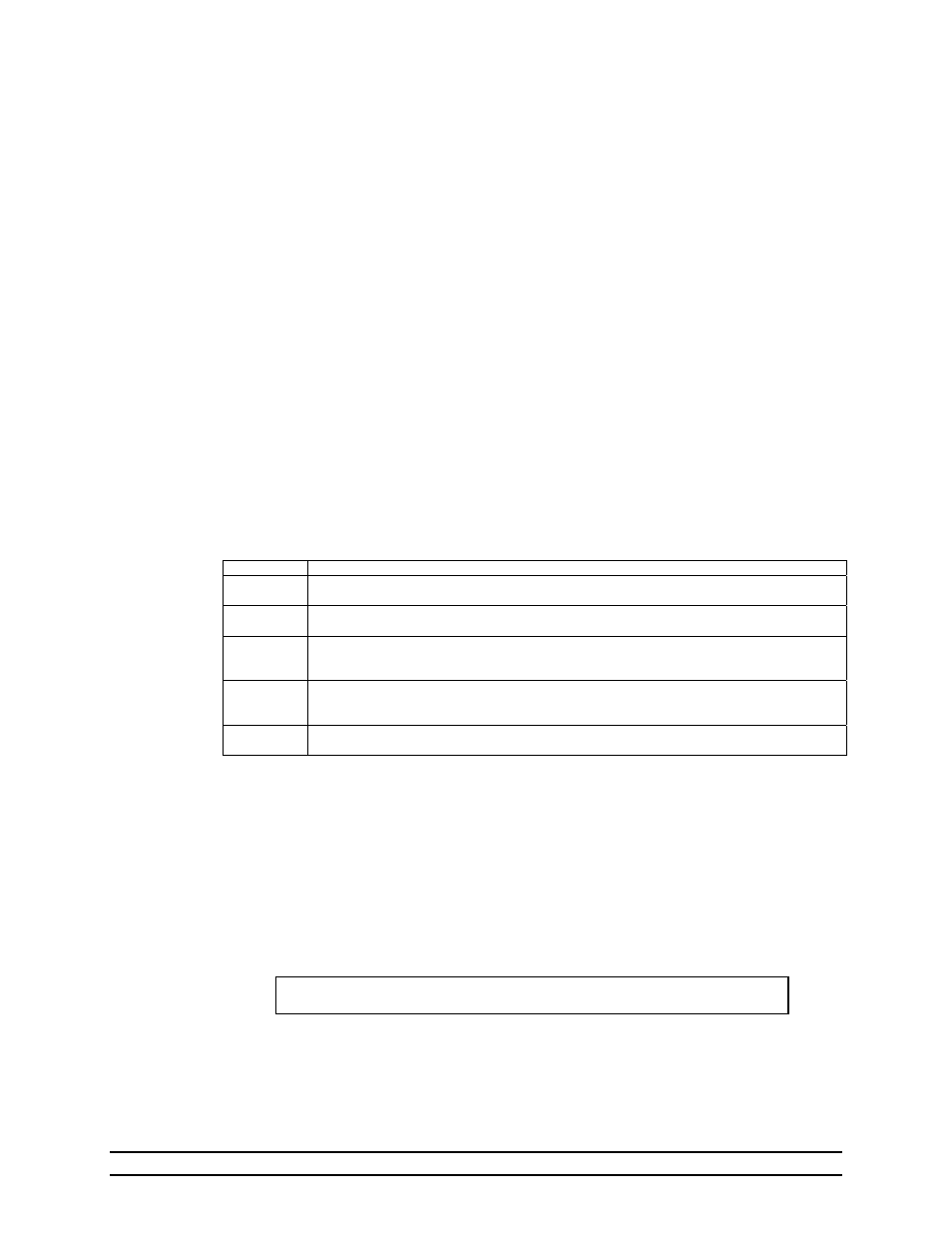

The controller is programmed to operate single phase or three phase fan motors at their optimum

performance levels. Select the correct motor curve parameter (P11) for your particular application

from the following table.

6.3 Natural Ventilation

This controller runs 1 or 2 curtain machines independently. No additional resources – including

external timers – are necessary. The curtain machines run off a common cycle timer and run

timer, however they can use separate sensors. The sensor selection is made via a switch located

on the inside of the front cover of the machine. This switch causes the machines to either operate

together or independently. If they are operating independently, unit 1 always uses sensor 1 and

unit 2 uses sensor 2.

A brief overview of the programmable parameters for the curtain machines follows:

NOTE: Parameters P20-P24 are only used when using the main curtain to

naturally ventilate the building.

P20 – Curtain Cycle Time (min.)

The controller looks at all parameters and decides whether or not to move the

curtains occasionally. This parameter determines how often this occurs. Valid

settings are 1 to 10 minutes.

Curve

Conditions

0

This curve is optimized for use with Hired Hand’s line of Funnel Flow Fans that are 24” or less. Also,

line voltage must be Single Phase.

1

This curve lends itself better to operation of 36” fans. The power distributed at each percentage is

somewhat greater than that of curve 0. Therefore, the speed will be a little greater than that of curve 0.

2

This curve is for 3-Phase systems. Its purpose is to shift the voltage curve to give a much higher power

from the varied phase. Conditions that would warrant the use of this curve is a variable speed fan that

varies a great deal from 100% speed to 95% speed.

3

This curve is for 3-Phase systems. Its purpose is to shift the voltage curve to give much less power from

the varied phase. Conditions that would warrant the use of this curve is a variable speed fan that varies

very little from 100% speed to 5% speed.

4

This curve is for use with Hired-Hand’s newest Emerson fan motor. These motors are typically used on

fans that are 24” or smaller.