0 installation, Warning – Hired-Hand Universal Ray Tube Heaters: AG1 Series User Manual

Page 6

6

2.0

Installation

2.0

Installation • Electrical Requirements

Instructions for the following are detailed in the Tube Heater General Manual:

• Design considerations

• Hanger suspension and placement (

Note: Placement for poultry facilities on page 9).

• Tube layout and assembly

• Burner control box suspension

• Reflectors (and accessories)

• Venting and combustion air intake

• Gas requirements

• Baffle assembly

NOTE: Electronic versions of all manuals are available at www.detroitradiant.com.

AG1

Series

WARNING

!

!

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, serious injury or death. Read and understand, the installation, operating and

maintenance instructions thoroughly before installing or servicing this equipment. Only

trained, qualified gas installation and service personnel may install or service this equipment.

Not for residential use! Do not use this heater in the home, sleeping quarters, attached

garages, etc. Installation of a commercial tube heater system in residential indoor spaces

may result in property damage, serious injury or death.

Combustion Air

The combustion air intake collar is also a factory preset air orifice. Non-contaminated air for combustion

must be ducted to the heater in all agricultural applications. Do not take combustion air from pressurized

attic spaces, with the exception of broiler houses.

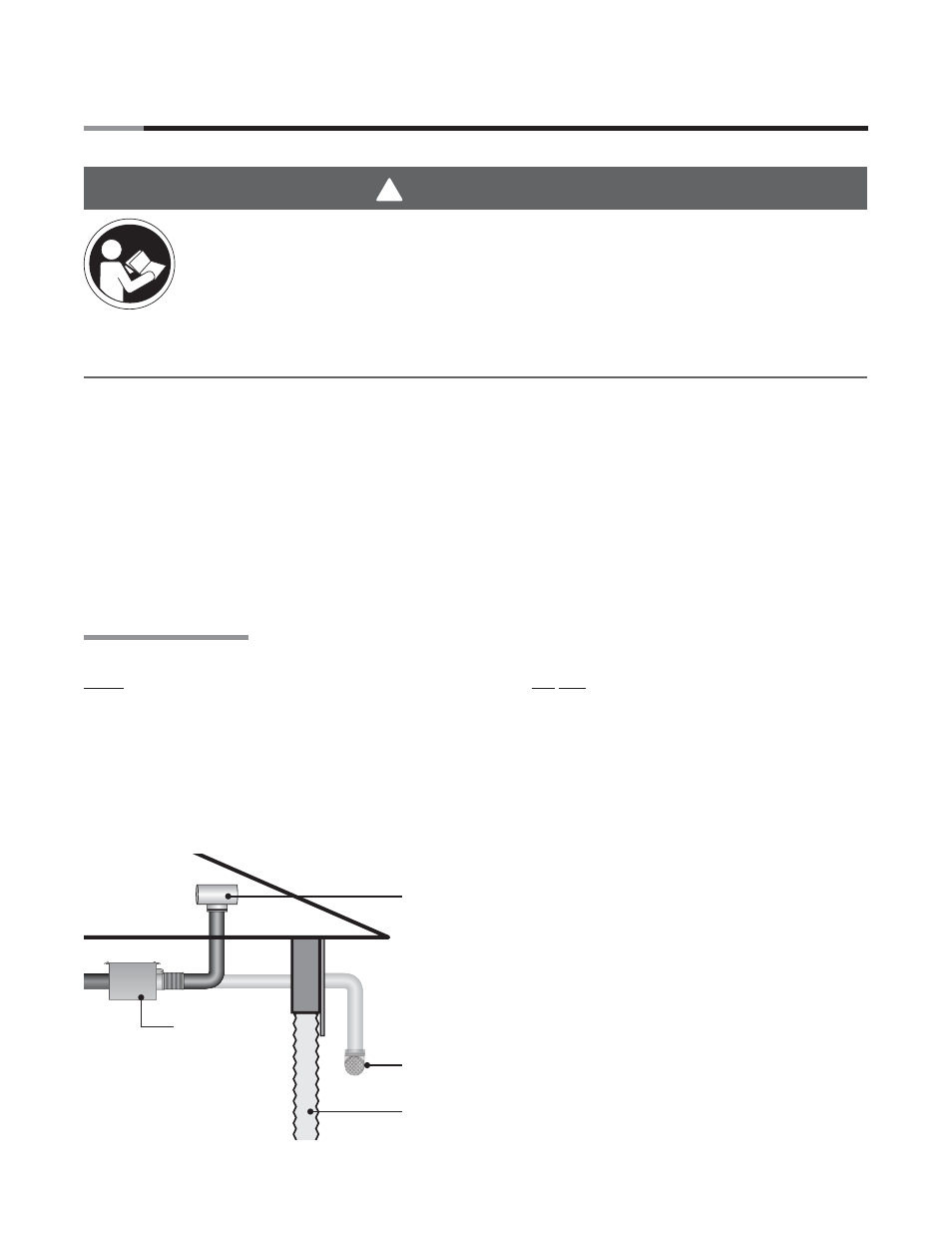

Locate the air intake away from any steam source. Use caution when locating air intake above curtain

walls, as they can leak. When curtain walls are present, use 4-inch light gauge PVC air intake material

from curtain sidewall to the heater; do not exceed 25 feet. With an elbow, drop intake one foot below the

top of the curtain wall. Cap intake with a 1/4-inch birdscreen. Figure 2.1.

Figure 2.1

•

Combustion Air Intake (Broiler House)

Burner

control box

Air intake

through attic

(broiler houses)

1/4 in. birdscreen

on plastic tee

Curtain wall