3 five-point linear calibration, 4 calculations example – Rice Lake Condec UMC600IS User Manual

Page 34

Calibration

31

4.3

Five-Point Linear Calibration

There are five calibration points (La, Lb, Lc, Ld, and Le) that can be entered sequentially. Calibrations using

fewer than five points will linearize the curve up to the last data point. The curve is then extrapolated from the last

entry point. For best results, use values of 20%, 40%, 60%, 80%, and 100% of full scale for the five linearization

points.

1. Turn on Option 6 (see Section 3.3.5 on page 23).

2. After performing a zero calibration as described in Section 4.1, place the first test weight on the scale

platform. Allow ten or more seconds for stabilization (motion LED goes out).

NOTE:

Straight averaging is applied during calibration.

3. Enter test weight value for the first calibration point using the numeric keyboard.

4. When the display is correct, press the

ENT

key. The display will read

CAL

briefly. The value of the last

calibration point entered will then appear with a flashing display prompt

L_

indicating the next

calibration point to be entered (Lb, Lc, Ld, or Le).

5. Repeat Steps 2, 3 and 4 for Lb, Lc, Ld, and Le with the appropriate test weights.

6. Recheck the zero weight by emptying the scale.

NOTE

: AZM is off during calibration. Dead load display provides signal reference.

7. When complete, open all switches on SW1.

8. Re-install faceplate overlay and bracket. Tighten the knurled fasteners. Seal the unit if used in a

legal-for-trade application.

Note:

If the response is more critical within a certain range, four of the five points can be in that area. The fifth point is

always 100% full scale.

4.4

Calculations Example

Capacity = 200,000 lb x 20 lb

Number of graduations = 200,000

÷ 20 = 10,000

Configuration:

•

Parameter 1 = 100 (10,000 graduations)

•

Parameter 2 = 20 (resolution)

•

Parameter 3 = 0 (no decimal point)

Other Factors to Note

AZM/PAZ: 1.9% x 200,000 = 3800 lb

Overrange: 103% x 200,000 = 206,000 lb

Minimum calibrated load: 10% x 200,000 = 20,000 lb

Analog Sensitivity

Analog signal input range: 0.7 to 3.2 mV/V

Analog signal sensitivity: 0.3

µV/graduations at 20,000

For H-44 requirements, use a factor of 4 (1.2

µV/grad). If the lower signal range is used for calibration, the

indicator may fail acceptance testing with 0.3

µV/grad.

NOTE:

Check for a minimum live load of 12 mV for 10,000 graduations. If less than 12 mV, increase the number of

graduations accordingly.

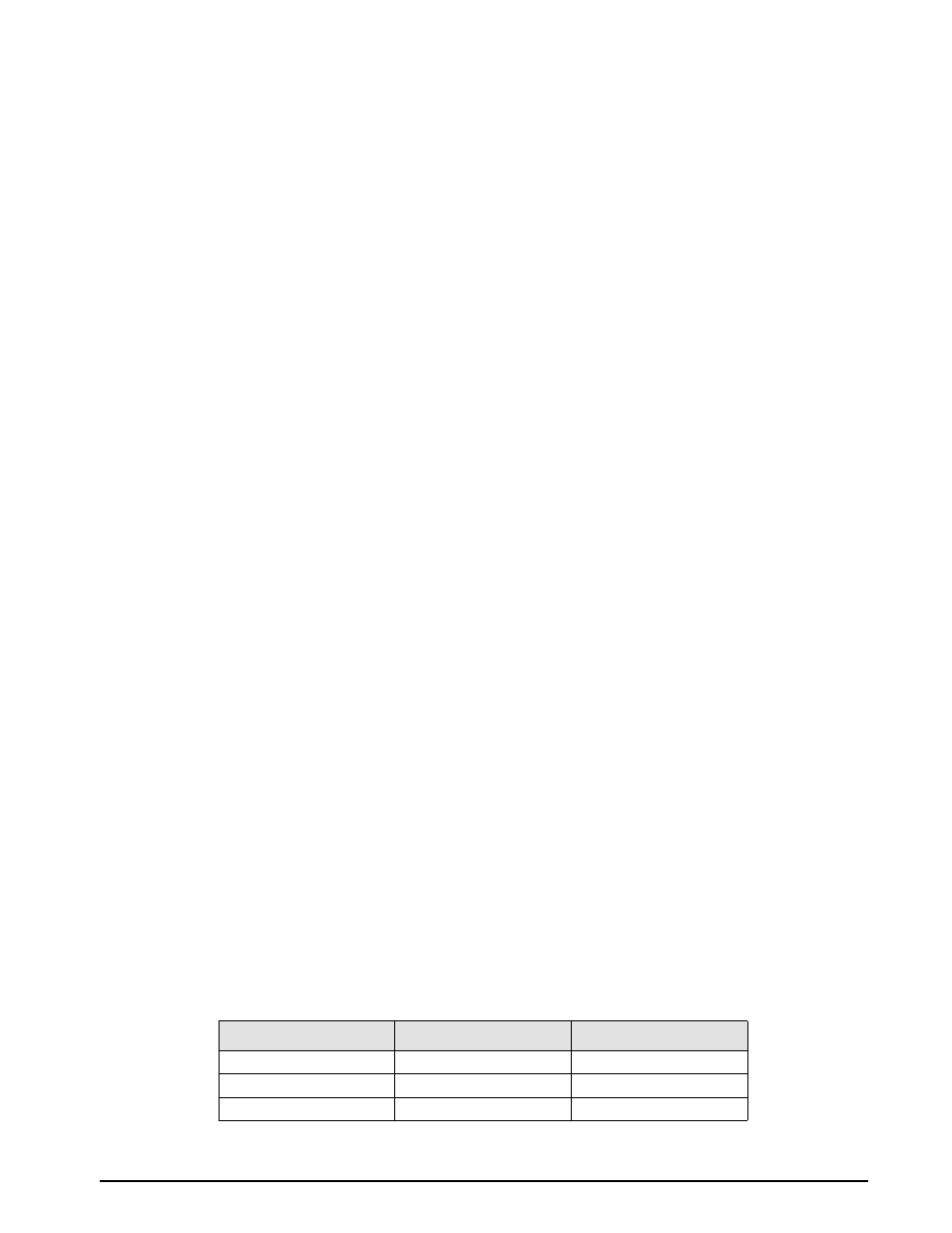

Live Load Signal Range

The following table gives examples to determine the live load signal range:

Load Cells

Rated at 2mV/V

Rated at 3mV/V

5V Excitation

2mV/V x 5V = 10 mV

3mV/V x 5V = 15 mV

Dead load (est)

2 mV

5 mV

Live load

8 mV

10 mV

Table 4-1. Live Load Range Signal Range