Watlow Series PD Ethernet Enabled Temperature and Process Controller User Manual

Page 25

W a t l o w S e r i e s P D

■

2 3

■

C h a p t e r 5 T r o u b l e s h o o t i n g

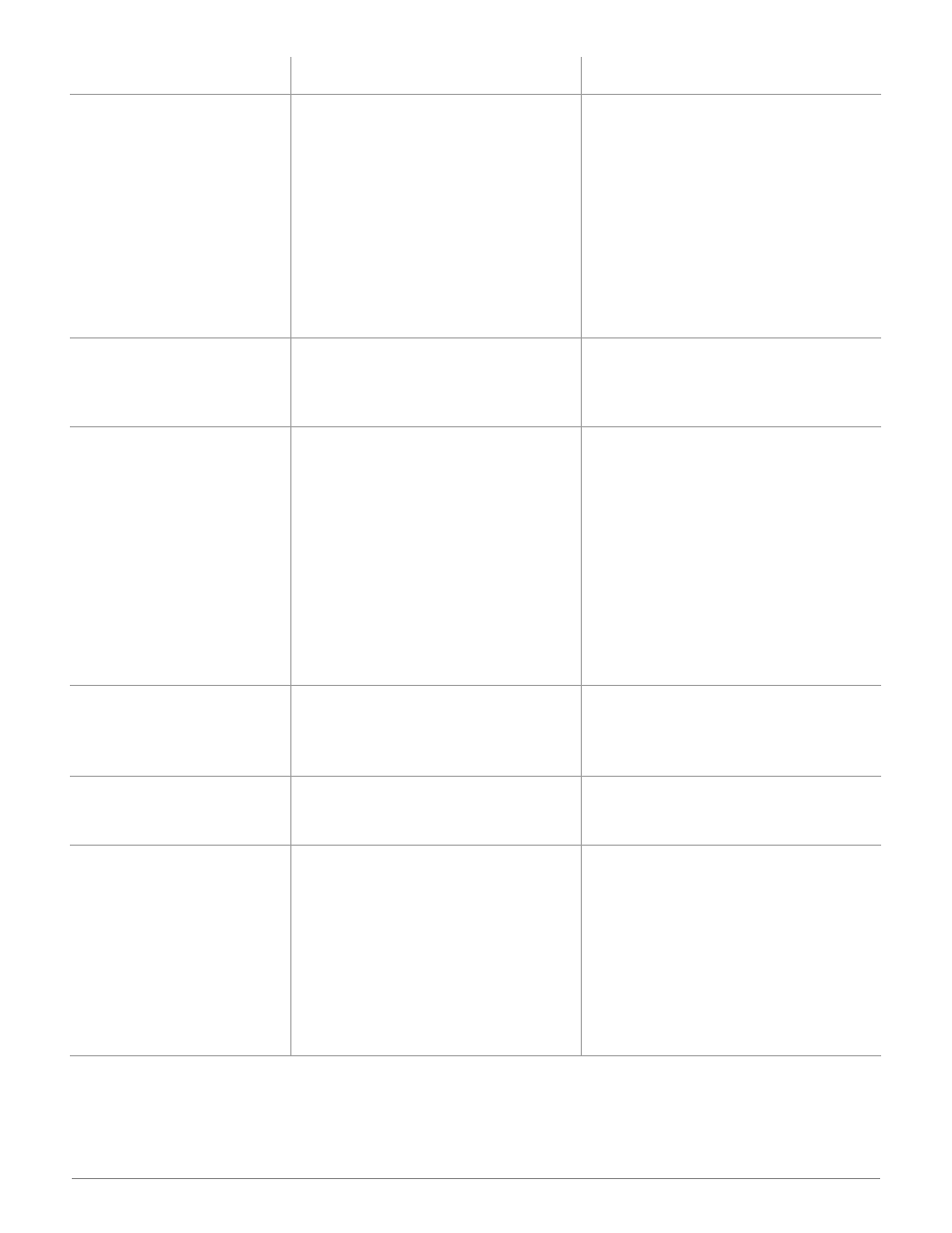

Indication

Probable Cause(s)

Corrective Action

Alarm will not activate or

clear.

• Controller is in Error condition.

• Alarm is in latched setting.

• Alarm is silenced.

• Incorrect configuration.

• Incorrect wiring.

• Wrong output type.

• Defective controller.

• Determine cause of error and correct.

• Wait for process to return to normal

and acknowledge alarm.

• Wait for process to return to normal

and alarm will work correctly.

• Configure Alarm, Alarm Set Point, Hys-

teresis, Silencing and Latching.

• Correct wiring.

• Replace controller with correct output

type.

• Repair or replace controller.

Controller's process value

reading is decreasing as the

actual process is increasing.

• Thermocouple is reversed wired.

• Analog voltage or current input scal-

ing is reversed.

• Check thermocouple wire for correct po-

larity.

• Configure correct scaling on Input page.

Controller does not control

close enough to set point.

• PID values incorrect.

• Cycle times incorrect.

• Heat or cooling capacity incorrectly

sized for application.

• Incorrect sensor placement.

• Controller is in Manual mode (open

loop).

• Control loop action configured incor-

rect.

• Tune controller (Auto Tune or Manual

Tune).

• Set cycle time to match hardware on

Control Loop .

• Size energy sources to match load.

• Place sensor in optimal location.

• Change to Auto mode (closed loop) on

Monitor page.

• Configure Control Loop Action on Con-

trol Loop page.

Output cycles (turns on and

off) too frequently.

• Wrong control mode. PID control se-

lected instead of ON-OFF control.

• The cycle time is set too short.

• Activate ON-OFF control on Output

page.

• Increase Output Cycle Time on Out-

put page.

Cannot access Security, Mon-

itor, Configuration or Cali-

bration page.

• Password is enabled and incorrect

password is supplied.

• Provide the correct user name and pass-

word.

Process value reads incor-

rectly

• Analog input is configured incorrectly.

• Thermocouple sensor shorted.

• Process sensor scaled incorrectly.

• Calibration offset is incorrect.

• Sensor is wired incorrectly.

• Controller calibration is incorrect or

corrupt.

• Defective controller.

• Configure control for appropriate sen-

sor input on Analog Input page.

• Repair wiring or replace sensor.

• Set scaling on Analog Input page.

• Correctly set calibration offset.

• Wire sensor per wiring section.

• Recalibrate controller.

• Repair or replace controller.