Wiring – Watlow Series TM User Manual

Page 8

Wa t l o w S e r i e s C

• 6 •

C h a p t e r 3 W i r i n g

Ó

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this con-

troller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment

and property, and/or injury or

loss of life.

Note: Insulated terminals re-

quired for quick connect style

terminals.

For quick connect terminals 1,

2, 6, 7, 8, 9, and 10, AMP P/N

3-520406-2 or equivalent recom-

mended. Use Amp crimp tool

P/N 58078-3, insert 90391-3.

For quick connect terminals 3, 4,

and 5, AMP P/N 2-520405-2 or

equivalent recommended. Amp

crimp tool P/N 58078-3, insert

58079-3.

The terminals on the back of the Series C and Series TM controllers are

the same for all of the package styles. They are 6.3 mm (0.25 in) quick connect,

push on style terminals or removable screw terminal block. The terminal style

is an ordering option.

Check the part number to determine your hardware configuration. Refer to

the wiring diagrams appropriate for your controller’s configuration.

All outputs are referenced to a de-energized state.

Wiring Guidelines

1. Use the correct thermocouple type per the model number on the case stick-

er of the unit. See dimension drawings for sticker locations.

• Use correct thermocouple polarity. Red is usually negative.

• If you must extend thermocouple leads, use thermocouple extension

wire to minimize errors.

• Be sure you have good crimp connections on your thermocouple con-

nections.

• Insulate the thermocouple mounting from the mounting surface to

prevent heat migration input errors.

• Thermocouple leads should be routed separately from any high voltage

lines.

• Long lead lengths create electrical resistance and there is not any lead

resistance compensation. When using a two or three-wire RTDs, there will

be an additional 2.6° C (4.7° F) error for every 1

Ω of lead length resistance.

That resistance when added to the resistance of the RTD element, can re-

sult in erroneous input to the temperature controller.

2. In electrically-noisy environments (heavy switching contactors, motors,

solenoids, etc.), use shielded thermocouple lead wire with the shield con-

nected at the sensor end only.

3. Use a separate thermocouple to maintain the limit function of this

controller; do not parallel thermocouple input from the primary controller.

4. All wiring and fusing must conform to the National Electric Code (NEC)

NFPA70 and any other locally applicable codes.

5. Fuse the independent load voltage on the L1 (hot) side and connect it to

the common (C) side of the relay.

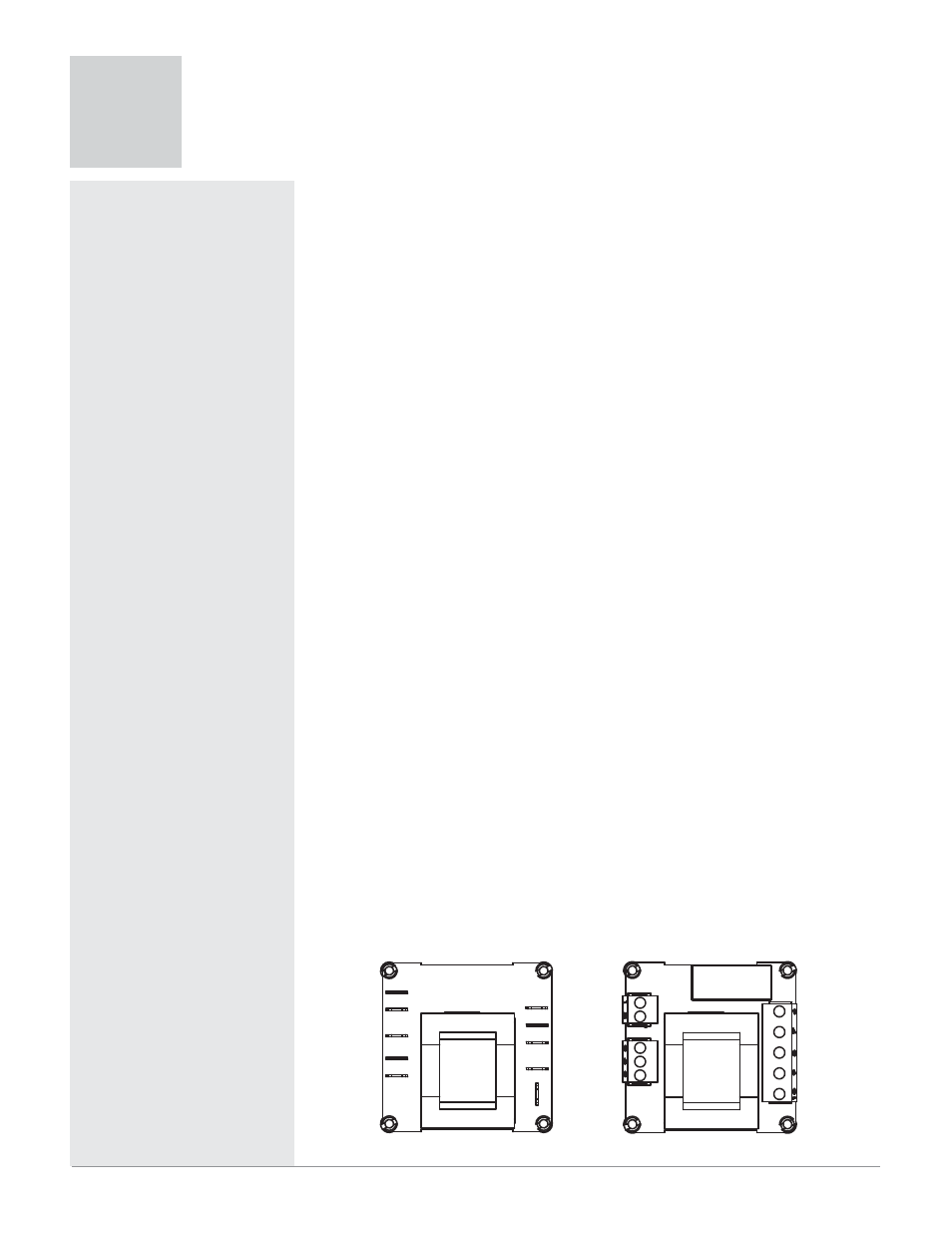

Note: The model number determines the connection terminal style. See below for terminal locations.

1

2

3

4

5

6

10

9

8

7

1

2

3

4

5

6

10

9

8

7

Wiring

3