Watlow Series TM User Manual

Page 18

Wa t l o w S e r i e s C

• 1 6 •

Tr o u b l e s h o o t i n g

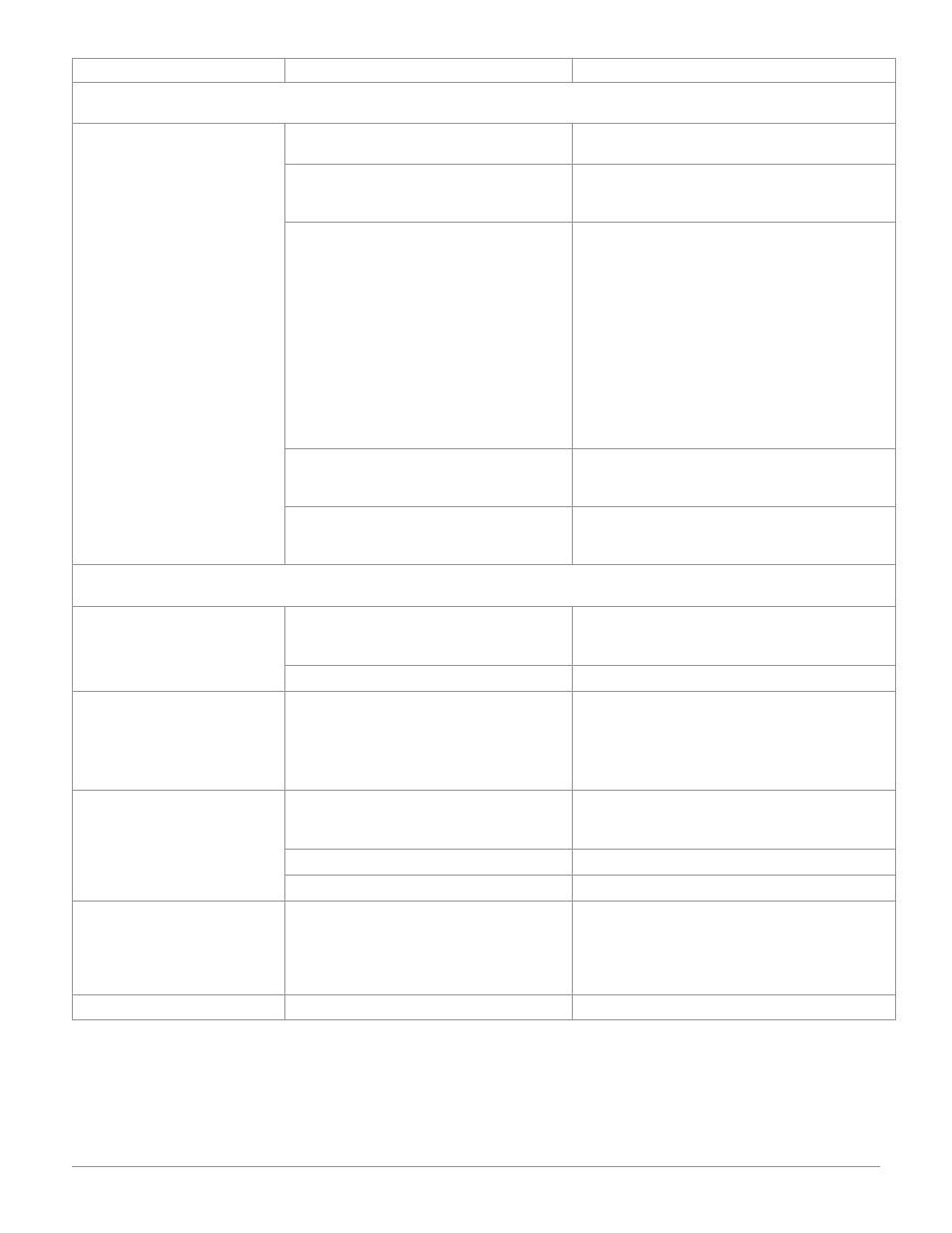

Indication

Probable Cause(s)

Corrective Action

Troubleshooting RTD inputs

Temperature reading is in-

correct, showing a sensor er-

ror,

[Er;In] , or LOAD LED

is switching at the wrong

temperature.

• Calibration offset incorrect (tactile

models only).

Check calibration offset

• Settings for degree C or F is incorrect. Check model part number for degree C or F.

If model has Increment/Decrement keys then

C/F setting is adjustable.

• Sensor or controller may be bad. Sen-

sor connections may be bad.

• Place a 110 ohm resistor across the sensor

input terminals. The display should indicate

25°C (77°F). If it does, the controller is OK.

Sensor or connections may be bad.

For controllers without the ability to view

process temperature:

- Decrease set point below ambient tempera-

ture, LOAD LED should be off for heating

controllers and on for cooling controllers.

- Increase set point above ambient tempera-

ture. LOAD LED should be on for heating

controllers and off for cooling controllers.

• Ambient temperature in the control

cabinet is over 70°C (158°F).

• Measure temperature in cabinet to ensure

it is below 70°C (158°F). Vent cabinet or add

fans if necessary.

• Sensor connections may be bad. Ex-

cessive lead wire resistance.

• Check sensor connections. Measure lead

wire resistance. There will be a 2.6°C (4.7°F)

error for every ohm of lead wire resistance.

Troubleshooting controller outputs

Controller output signal is

not on when it should be.

Load LED is not on.

• Temperature reading is incorrect on

display of indicating controls or limit.

See input troubleshooting.

• See input troubleshooting.

• Set point is not set correctly.

• Verify set point setting.

Controller output signal is

not on when it should be.

Load LED is on.

• Output wiring is incorrect.

• Verify wiring. Relay outputs act as a

switch, they do not source power.

For DC output controls, voltage should be

about 20VDC with no load. Greater than 5

volts with load of 500

Ω or greater.

Control output signal is on

when it should not be on.

Load LED is on.

• Temperature reading is incorrect on

display of indicating controls or limit.

see input troubleshooting.

• See input troubleshooting.

• Set point is not set correctly.

• Verify set point setting.

• Control output is defective.

• Repair or replace controller.

Load is on when it should

not be on. Load LED is off.

• Power switching device (SSR, HG

relay, mechanical relay) is shorted. Con-

troller outputs shorted.

• Remove wires from output of control to in-

put of power switching device. If load is still

on, replace power switching device. If load

turns off, replace controller or sensor. See in-

put troubleshooting.

• Output wiring is incorrect.

• Verify wiring.